York E1FB240 User Manual

Page 7

and/or drafts. Circulation of air to the thermostat should not

be blocked by curtains, drapes, furniture, partitions, etc.

Some installations may require a locking cover to protect the

thermostat from tampering and/or damage.

Both the manual and the auto changeover thermostats have

non-adjustable, voltage-type anticipators for both cooling and

heating.

REFRIGERANT PIPING

GENERAL GUIDELINES

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system

and by using procedures and materials that conform with es-

tablished standards.

Use hard drawn copper tubing where no appreciable amount

of bending around pipes or other obstructions is necessary.

Use long radius ells wherever possible with one exception -

small radius ells for the traps in all vapor risers. If soft copper

is used, care should be taken to avoid sharp bends which

may cause a restriction.

Pack fiber glass insulation and a sealing material such as

permagum around refrigerant lines where they penetrate a

wall to reduce vibration and to retain some flexibility.

Support all refrigerant lines at minimum intervals with suitable

hangers, brackets or clamps.

Braze all copper to copper joints with Sil Fos-5 or equivalent

brazing material. Do not use soft solder.

Insulate all vapor lines with a minimum of 1/2" ARMA-FLEX or

equal. Liquid lines exposed to direct sunlight and/or high tem-

peratures must also be insulated.

Never solder vapor and liquid lines together. They can be taped

together for convenience and support purposes, but they must

be completely insulated from each other.

LINE SIZING

When sizing refrigerant lines for a split-system air conditioner,

check the following:

1. Suction line pressure drop due to friction at full capacity,

2. Liquid line pressure drop due to friction at full capacity,

3. Suction line velocity for oil return at part capacity, and

4. Liquid line pressure drop due to static head.

NOTE: Never base refrigerant line sizes on the OD of the suc-

tion and liquid connections on the unit.

Tables 4 and 5 list friction losses for both the suction and liq-

uid lines on the system. Table 6 shows the amount of refrig-

erant charge required per foot of refrigerant line.

When the evaporator coil is below the condensing unit, the

suction line must be sized for both pressure drop and for oil

return. For certain piping arrangements, different suction line

sizes may have to be used. The velocity of the suction gas

must always be great enough to carry oil back to the compressor.

When the condensing unit is below the evaporator coil, the

liquid line must be designed for the pressure drop due to

both friction loss and vertical rise. If the total pressure drop

exceeds 40 psi, some refrigerant may flash before it reaches

the thermal expansion valve. This flashing will not only

cause erratic valve operation and poor system performance,

but could also damage the expansion valve.

SERVICE VALVES

These outdoor units have both vapor and liquid line service

valves.

Both valves are shipped from the factory front-seated and

closed with the valve stem in the maximum clockwise posi-

tion.

These service valves are the back-seating type and have a

1/4" male flare access port for evacuating and charging the

system.

Shrader access valves are provided on the compressor va-

por and discharge lines for pressure checking the system.

All access ports are sealed with a removable cap. Never re-

move a cap unless the valve is fully back-seated with its

valve stem in the maximum counter-clockwise position be-

cause the refrigerant charge will be lost.

INSTALLATION

Since these units are shipped with a holding charge of

Refrigerant-22, they can be checked for a refrigerant leak by

opening the access port on the liquid line service valve as fol-

lows:

1.

Open the valve by turning the stem to its maximum counter-

clockwise position.

2.

Remove the cap from the access port.

WARNING: Provisions for recovering refrigerant releases

must be available during all phases of installa-

tion, leak testing and charging. Do NOT re-

lease refrigerant into the atmosphere.

Unitary Products Group

7

035-16192-001-A-1001

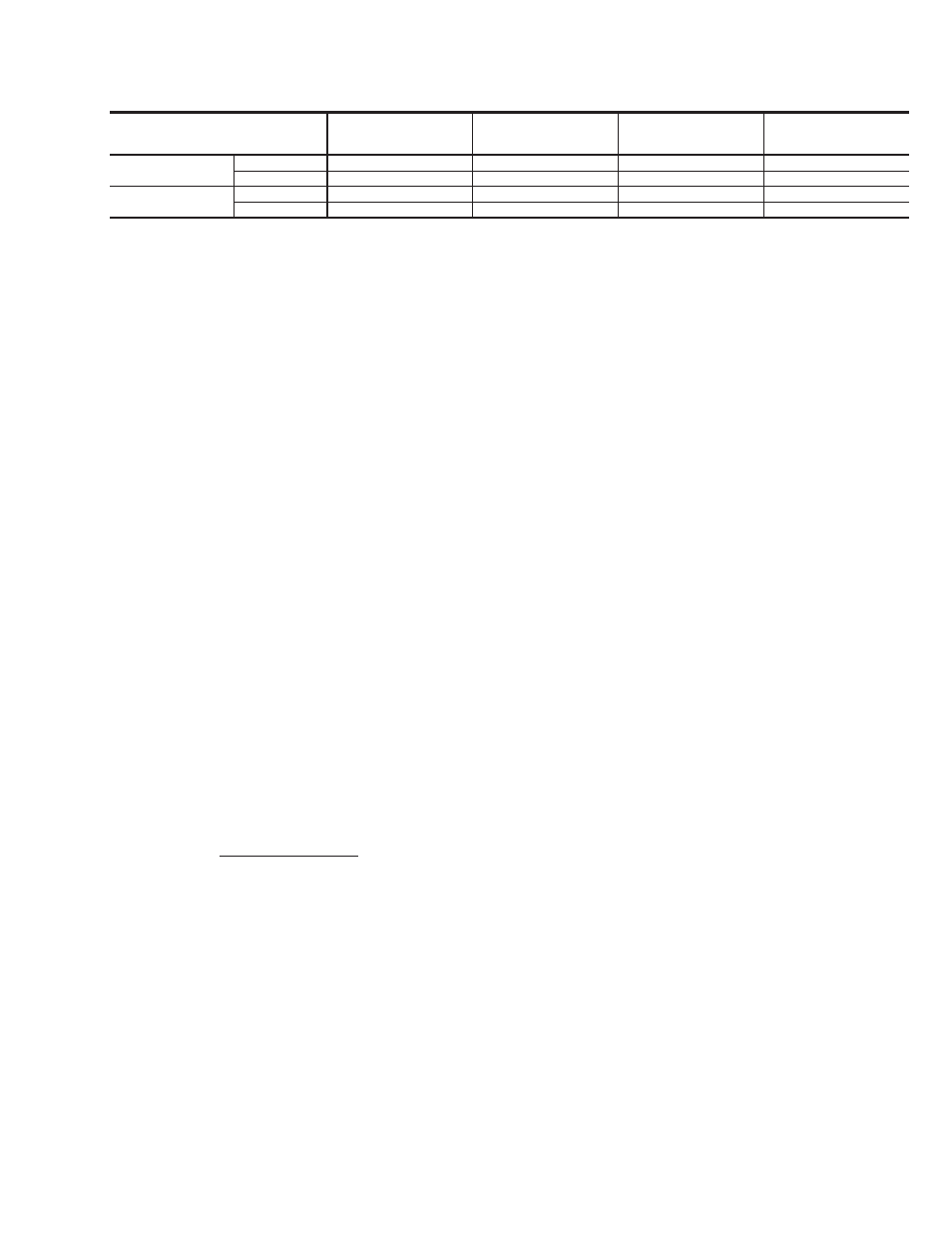

Model

Designation

Nominal

Capacity

(Tons)

Refrigerant

Flow Rate

3

(Lbs./Min.)

Type L

Copper Tubing

(Inches O.D.)

Friction

Loss

4,5

(PSI/100 Ft.)

180

System 1

7-1/2

22.5

1-1/8

4.7

System 2

7-1/2

22.5

1-1/8

4.7

240

System 1

10

30

1-3/8

2.8

System 2

10

30

1-3/8

2.8

1

All horizontal suction lines should be pitched at least 1 inch every 20 feet in the direction of the refrigerant flow to aid the return of oil to the compressor.

2

Every vertical suction riser greater than 25 feet in height should have a “P” trap at the bottom to facilitate the return of oil to the compressor. Use short radius fittings for these traps.

3

Based on Refrigerant-22 at the nominal capacity of the condensing unit, a suction temperature of 40

°

F and a liquid temperature of 105

°

F.

4

Although suction lines should be sized for a friction loss equivalent to a 2

°

F change in saturation temperature (or approximately 3 psi), sizing the lines for the proper return of oil

is more important.

5

These friction losses do not include any allowances for valves or fittings.

6

Since the refrigerant gas velocity may be too low to maintain good oil return up a vertical riser, use the next smaller size. The larger size may be used for horizontal runs for a smaller

pressure drop.

TABLE 4 - SUCTION LINES

1,2