Whirlpool EDP/EDN User Manual

Page 9

Endurance

Page 9

1.

Run gas supply line in accordance with all

applicable codes.

2.

Locate and install manual shutoff valves in

accordance with state and local requirements.

3.

Install drip leg, ground joint union and drip cap

to trap sediment and for test gauge access.

4.

Support all piping with proper hangers.

5.

All threaded joints should be coated with piping

compound resistant to the action of liquefied

petroleum gas.

6.

The boiler and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of ½ psig (3.5kPa).

7.

The boiler must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psig (3.5kPa)

8.

The boiler and its gas connection must be leak

tested before placing the boiler in operation.

9.

Purge all air from gas lines.

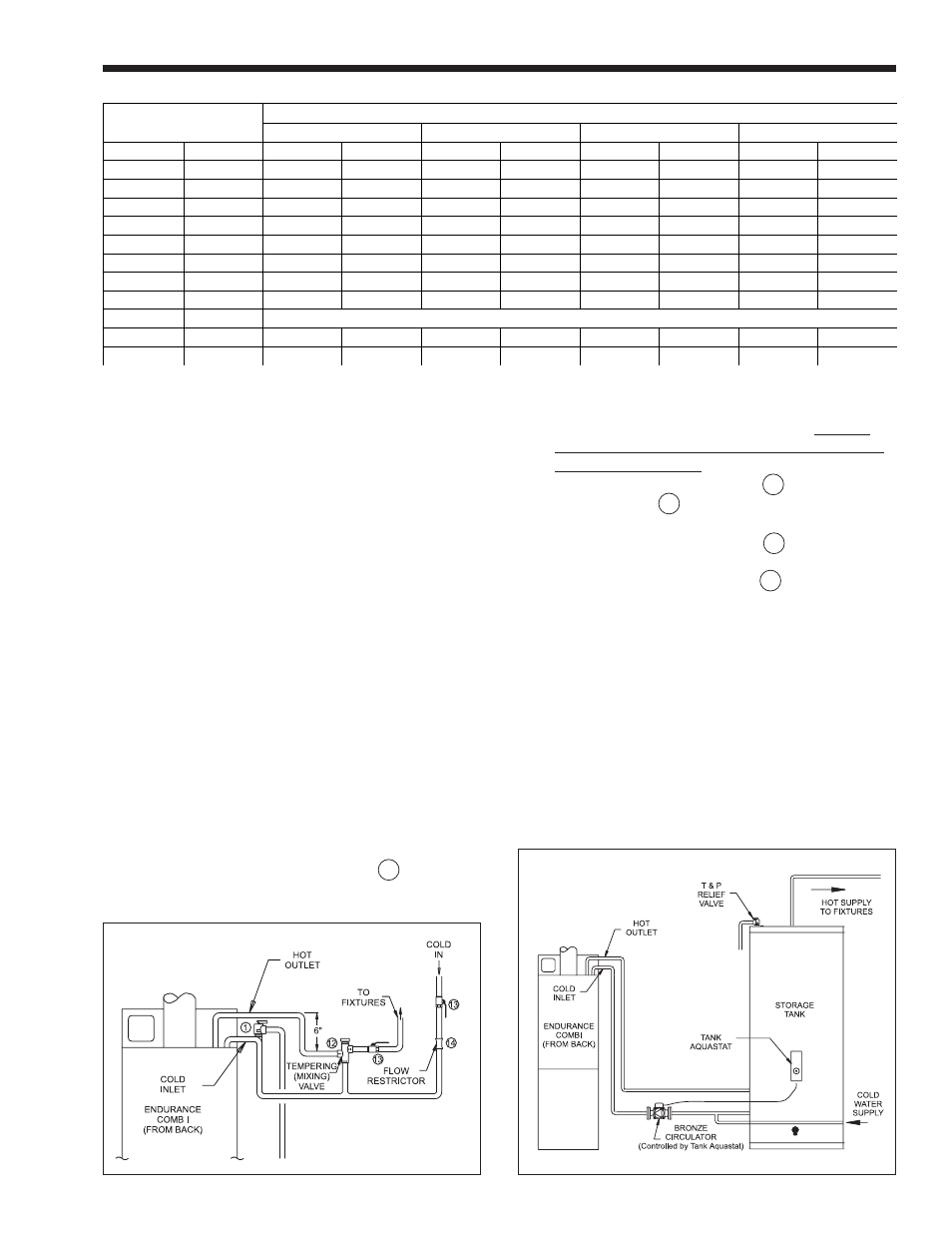

3B. Domestic Water Piping (EBP only)

1.

Connect tempering (mixing) valve 12 “Hot” port

to hot water outlet from unit. This valve should

Figure 12. Domestic Water Piping.

Figure 13. Domestic Water Piping With Storage Tank.

be no higher than 120°F mixed delivery

temperature or as local codes dictate. LAARS

RECOMMENDS ANTI-SCALD TEMPERING

(MIXING) VALVES (see Figure 12).

2.

Connect gate or shutoff valve 13 to tempering

(mixing) valve 12 “MIX” port, and cold

water inlet.

3.

Install supplied flow restrictor 14 ahead of

tempering (mixing) valve tee.

4.

Connect pressure relief valve 1 (if required by

codes), maximum 150 PSI as close to the unit as

possible. No other valves or restrictions may be

installed between the Endurance and the relief

valve.

DO NOT USE A TEMPERATURE/PRESSURE

RELIEF VALVE AS THIS IS NOT A STORAGE

HOT WATER HEATER.

Note: Installations with water containing 10

or more grains of hardness, must be installed with

appropriate water treatment.

Length

of Pipe

Capacity of Pipe

1/2"

3/4"

1"

1-1/4"

ft.

m

MBTU/h

kW

MBTU/h

kW

MBTU/h

kW

MBTU/h

kW

10

3

132

38.7

278

81.5

520

152.4

1050

307.7

20

6.1

92

27

190

55.7

350

102.6

730

213.9

30

9.1

73

21.4

152

44.5

285

83.5

590

172.9

40

12.2

63

18.5

130

38.1

245

71.8

500

146.5

50

15.2

115

33.7

215

63

440

128.9

75

22.9

93

27.2

175

51.3

360

105.5

100

30.5

79

23.1

150

44

305

89.4

150

45.7

64

18.8

120

35.2

250

73.3

Additional length to be added for each tee or bend

ft

m

ft

m

ft

m

ft

m

1.3

0.4

1.7

0.5

2.2

0.7

2.7

0.8

Table 3.