Whirlpool EDP/EDN User Manual

Page 8

Page 8

LAARS HEATING SYSTEMS

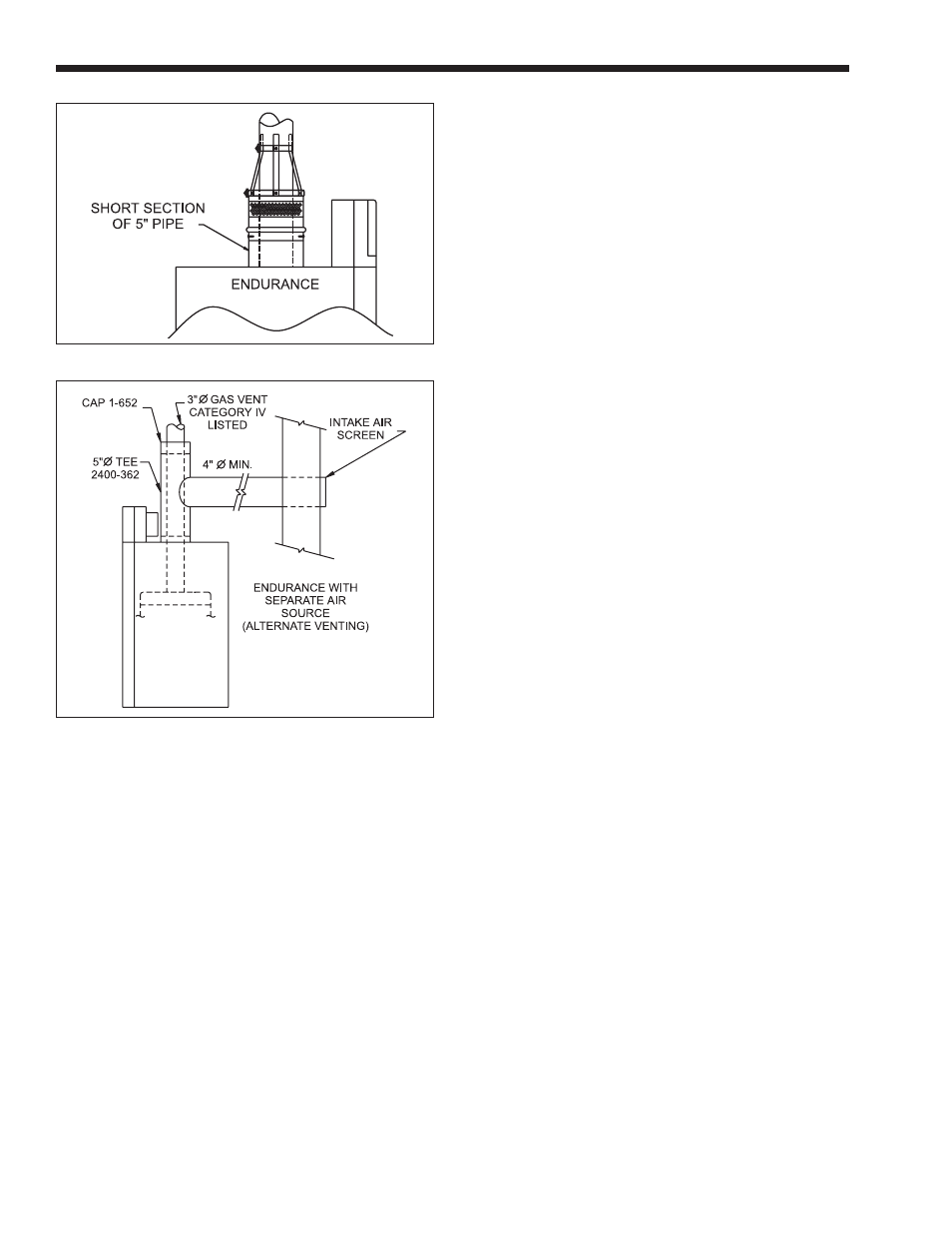

Figure 11. Non-Concentric Combustion Air Source.

(6.5 sq. cm) per 1,000 BTU/hr (293W) boiler

input, but not be less than 100 square inches

(645.2 sq. cm). These openings shall freely

connect with areas having adequate infiltration

from outside.

3.

When all air is provided from outdoors, the

confined space shall be provided with one

opening within 12" of the ceiling. This opening

shall connect directly, or by ducts, with outdoors

or spaces (crawl or attic) that freely connect

with the outdoors, and shall have a minimum free

area of:

a.

1 sq. in. per 3000 BTU/hr (7 cm

2

/kw) of the

total input rating of all equipment located

in the enclosure, and

b.

Not less than the sum of the areas of all

vent connectors in the confined space.

2F. Connecting Special Gas Vent

to the Appliance

Part number 2400-372 is used with a vent

terminal (p/n 2400-277) to secure the 3 inch special

gas vent to the flue outlet of the appliance. Heat-Fab

pipe or fittings (p/n 2400-350 or 2400-352) or the male

end of Z-Vent pipe (Z-Vent # 02 SVEPXX030) may

be installed over the flue outlet of the Appliance (see

Figure 10).

2G. Securing Special Gas Vent

Attach p/n 2400-277 with sheet metal screws to

the 5" collar on the appliance with a short piece of 5"

pipe or to the end of the 5" combustion air duct.

Attach p/n 2400-372 bracket and tighten clamp. Form

the tabs on the bracket onto the special gas vent pipe

and secure the tabs with the 3" clamp. After the clamp

has been tightened, fold the end of the tabs down over

the clamp (see Figure 10).

DO NOT use screws in any portion of the 3"

special gas vent.

When providing combustion air from another

location, the connection of the 5" duct to the appliance

must be secured with sheet metal screws.

Each 5" joint in the 5" duct must be secured with

sheet metal screws.

In this type of installation, p/n 2400-372 must be

used to secure the special gas vent at the point where it

exits the duct. The combustion air supply should be

protected from debris entering the duct with an

appliance vent terminal, p/n 2400-277, as shown in

Figure 8 or with a large mesh screen.

Follow the special gas vent manufacturer's

instructions for cleaning and sealing all parts before

assembling.

Apply ¼" bead of silicone sealer (GE108 or

Novagard 400) to the 3" flue outlet of the appliance

approximately 1" from the end.

Slide 3" inner vent pipe or 1-880 adapter, when

using outer 3" telescoping section, over the appliance

flue outlet and push down to stop (do not force pipe

beyond stop).

Apply another bead of silicone around this joint

and smooth out.

Apply ¼" bead of silicone to subsequent 3" joints.

An alternate, nonconcentric combustion air

source may be installed (as shown in Figure 11),

provided that the minimum 4" diameter combustion air

duct does not exceed 15' (4.6m). Termination should

include an air screen and be located in a qualified air

space (see Section 2E) or outside.

SECTION 3.

3A. Gas Piping

The appliance requires an inlet gas pressure of at

least 4" w.c. (1.0kPa) and no greater than 13" WC

(3.2kPa). Check with your local gas utility or supplier

for availability of this pressure range.

Refer to Table 3 to size the supply piping to

minimize pressure drop between meter or regulator

and unit.

Figure 10. Special Gas Vent Connection.