Troubleshooting — procedure, Gold cga gas-fired water boiler — boiler manual, Check the following – Weil-McLain Gold CGa User Manual

Page 50

GOLD CGa Gas-Fired Water Boiler — Boiler Manual

50

Part Number 550-101-009/0107

Troubleshooting — procedure

(continued)

11a

Check the following:

1. Wire connectors to control module are securely

plugged in at module and originating control.

. Gas pressures:

a. With boiler off — 13” w.c. maximum natural

or propane gas pressure upstream of gas valve.

b. With boiler on:

• 5” w.c. minimum natural gas pressure or

11” w.c. propane gas pressure upstream of

gas valve.

• 3.5” w.c. minimum natural gas pressure or

10” w.c. propane gas pressure downstream

tapping on gas valve — Can be adjusted by

regulator on gas valve.

In event of vent damper

failure:

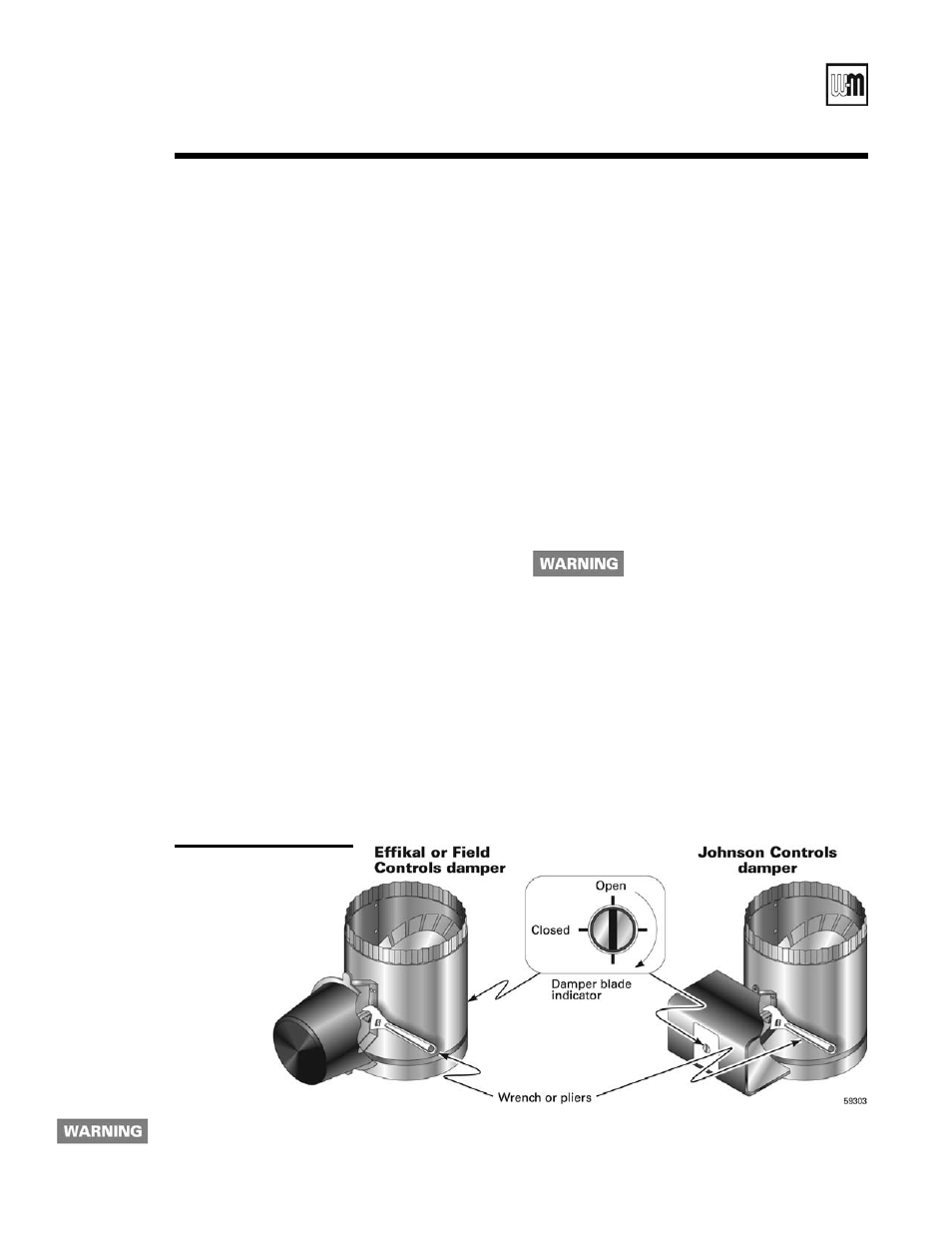

Effikal or Field Controls damper

If troubleshooting chart recommends replacing actua-

tor and actuator is not immediately available, damper

blade can be fixed in an open position to allow boiler

operation. Manually turning blade can cause actuator

damage. Follow these instructions only in case of no

heat or damper actuator malfunction.

1. Move damper service switch to

Hold Damper Open

position. Apply call for heat to boiler. Damper blade

should then rotate to open position and boiler will

fire.

. If step 1 does not open damper, manually rotate

• Verify proper operation after servicing. • See vent damper manufacturer’s instructions packed with vent damper

for additional information. Failure to comply could result in severe personal injury, death or substantial property

damage.

Figure 28

Manually

opening the

vent damper

damper blade to open position using wrench or

pliers on flat shaft between damper and actuator.

Boiler will fire. Verify that damper service switch is

in

Hold Damper Open

position. (

Figure 28

)

3.

Do not leave vent damper permanently in this

position.

Replace actuator immediately. If vent

damper is left in open position, boiler will not oper-

ate at published efficiencies.

Johnson Controls damper

If troubleshooting chart recommends replacing actuator

and actuator is not immediately available, damper blade

can be fixed in an open position to allow boiler opera-

tion. Follow these instructions only in case of no heat

or damper actuator malfunction. See

Figure 28

.

1. Turn off power to boiler.

Failure to turn off power to boiler

can result in severe personal injury,

death or substantial property dam-

age.

. Refer to vent damper manufacturer’s instructions

for procedure to fix vent damper in open position.

3. Turn on power to boiler.

4. Using wrench or pliers on flat shaft section, manu-

ally rotate damper blade until green light turns on.

Boiler will fire. (

Figure 28

)

5. Do not leave vent damper permanently in this posi-

tion. Replace actuator immediately. If vent damper

is left in open position, boiler will not operate at

published efficiencies.