86038510pg4-1, Maintenance, Warning – Windsor Wave WAV 10125050 User Manual

Page 11

MAINTENANCE

WAV 86038510 05/15/07

4-1

NOTE: T

HE FOLLOWING SERVICE ITEMS SHOULD BE PERFORMED BY

AN AUTHORIZED SERVICE FACILITY OR AUTHORIZED SERVICE

PERSONNEL

. A

LL PARTS REFERRED TO IN THESE INSTRUCTIONS CAN

BE IDENTIFIED BY USING THE PARTS LISTS AND ILLUSTRATIONS ON THE

FOLLOWING PAGES

.

REMOVE MACHINE POWER CORD FROM ELECTRICAL

SOURCE BEFORE MAKING ANY REPAIRS OR

ADJUSTMENTS TO THE MACHINE.

TO ACCESS BELT/BRUSH MOTOR

1. Place machine in the upright storage position.

2. Remove (3) screws holding belt cover to chassis.

3. Loosen brush motor and roll belt off brush pulley.

4. Remove (5) screws holding brush housing to

chassis- (3) Located on front of housing,

(2) Located rear of housing.

5. Remove (2) screws from each end of brush housing

and remove brush assembly.

6. Inspect/replace brush and bearings as required. The

brush is equipped with a yellow wear indicator

bristles. The brush should be replaced when it wears

down to the height of the yellow bristles.

7. When installing belt push down on motor for proper

tension.

8. When reinstalling brush, check belt for proper

tension.

TO ACCESS AND REMOVE VAC MOTOR

AND FILTERS

.

1. Open lid cover.

2. Remove (2) screws from each/both vac motor

brackets.

THE GREEN GROUND WIRE MUST ATTACH THE MOTOR TO

THE POWER CORD FOR SAFE OPERATION. SEE THE

WIRING DIAGRAM.

NOTE: WHEN REPLACING ELECTRICAL COMPONENT

PARTS REFER TO WIRING DIAGRAM FOR PROPER

CONNECTION.

NOTE: THE VAC MOTOR IS PROTECTED BY A CIRCUIT

BREAKER LOCATED IN THE SWITCH PANEL. THE BREAKER

WILL ONLY TRIP UNDER CONDITIONS OF ABUSE.

BRUSH MOTOR

1.

Access belt and brush as described above.

2. Disconnect spring holding frame to brush motor

housing.

3.

Remove (4) bolts holding motor housing to the

chassis and lift out motor asm.

4.

Remove brush motor pulley and (2) bolts holding

motor to bracket, lift out brush motor.

CARBON BRUSH

1. Access belt and brush as described above.

2. Remove brush caps. NOTE: BRUSHES SHOULD BE

REPLACED WHEN WORN TO 3/8” OR LESS.

NOTE: BEFORE REINSTALLING BRUSH MOTOR BRACKET

ASSEMBLY IT’S RECOMMENDED THAT THE REAR SPRING

BE RECONNECTED TO THE FLAPPER ASSEMBLY.

NOTE: PART NO. 86001250 – PRV NO. 140212 IF YOU HAVE

A MOTOR MARKED “LEESON.” PART NO. 86135360 – PRV

NO. 14340 IF YOU HAVE A MOTOR MARKED “86247470 – PRV

NO. 53617.”

!

WARNING

!

W A R N I N G

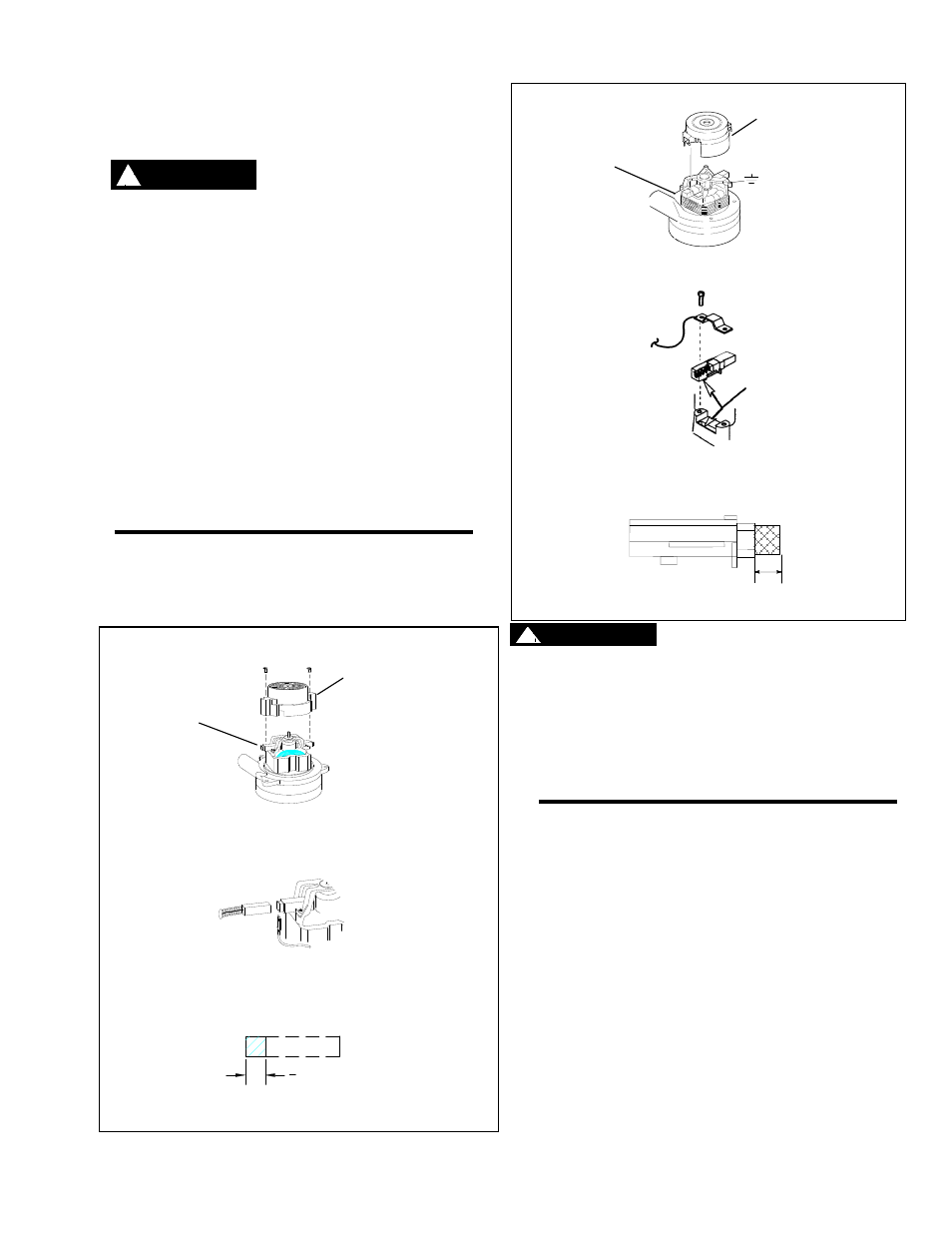

Vacuum Motor Carbon Brushes Replacement (Windsor)

End Cap

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a qualified

service center.

Important:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage motor if

brushes are allowed to wear away completely.

Periodically check the length of the carbon brushes. Replace both

carbon brushes when either is less than 3/8" (9.5mm) long.

3

8

[9.5mm]

Vacuum Motor Carbon Brushes Replacement (Ametek)

End Cap

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a qualified

service center.

Note:

Place

stop in

groove.

Important:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage motor if

brushes are allowed to wear away completely.

Periodically check the length of the carbon brushes. Replace both

carbon brushes when either is less than 3/8" (9.5mm) long.

3/8 (9.5mm)