Detailed service procedures – Weil-McLain 550-141-830/1202 User Manual

Page 9

9

Cleaning boiler flueways:

Make sure all electrical connec-

tions to boiler are turned off and wait until boiler

is warm, not hot, before cleaning. Failure to do so

will result in severe personal injury, death or

substantial property damage.

1. Top flue boilers -remove breeching and jacket

top panel.

Rear flue boilers - remove jacket top panel.

2. Remove flue collector hood, saving hardware

for reassembly.

3. Shut off oil valves. Arrange drip pans under

the areas of oil piping that will be discon-

nected.

Disconnect oil line at burner so

that

you can swing open the door complete-

ly.

4. Line combustion chamber floor with news-

paper to catch any soot that will be loosened

in the cleaning process.

5. Starting at the top of the boiler, use a wire

flue brush to thoroughly clean between all

pins at all angles. Be careful not to damage

side wall of rear refractory.

6. Move to the bottom of the flueways and clean

up between the sections to reach pins left

uncleaned in step #5.

Thoroughly clean flueways

between all pins at all angles.

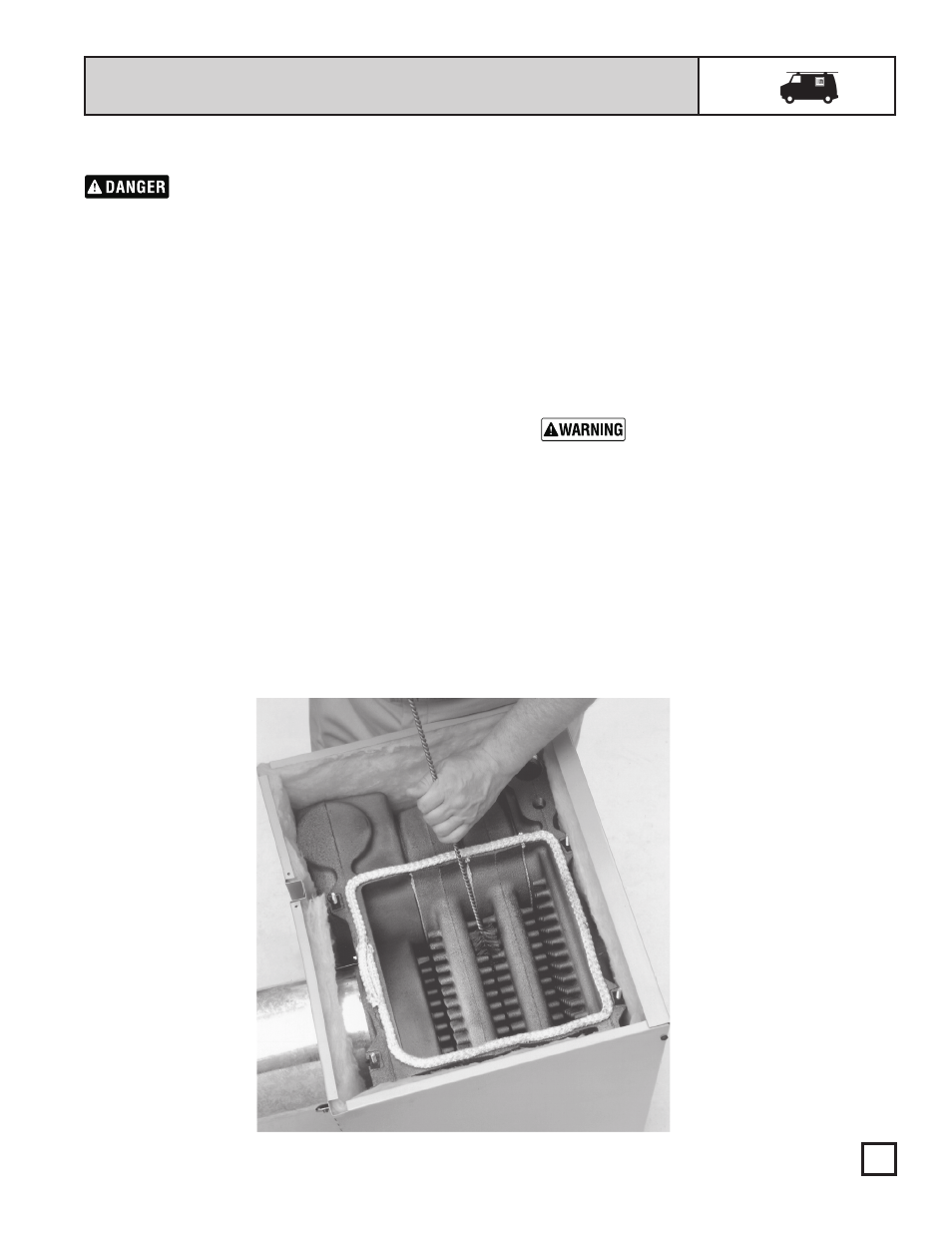

Start on top of boiler,

finish from the bottom.

Cleaning Boiler Flueways

Figure 3

Detailed Service Procedures

7. Once the flueways are cleaned, carefully

remove the paper from the floor of the

combustion chamber.

8. Verify sealing rope around flue area is intact.

Visually check condition and position of

insulation in combustion chamber floor,

and the refractories at the rear of boiler and

in the burner mounting door. Replace any

parts as necessary.

9. Close burner mounting door and tighten nut

securely. Place flue collector hood on top of

boiler. Secure with hardware from step #2.

Maintain a gas-tight seal to

avoid possible flue gas leakage and carbon

monoxide emissions, which can lead to severe

personal injury or death.

10. Check breeching for sooting and clean if

necessary. Install jacket top panel and

breeching.

11. Reconnect oil line and all electrical connec-

tions.

Part No. 550-141-830/1202