Warning, End brackets, Securing center bearing bracket assembly – Wayne-Dalton TORQUE MASTER PLUS 9400 User Manual

Page 5: Securing door for spring winding, Cable adjustments, Winding springs

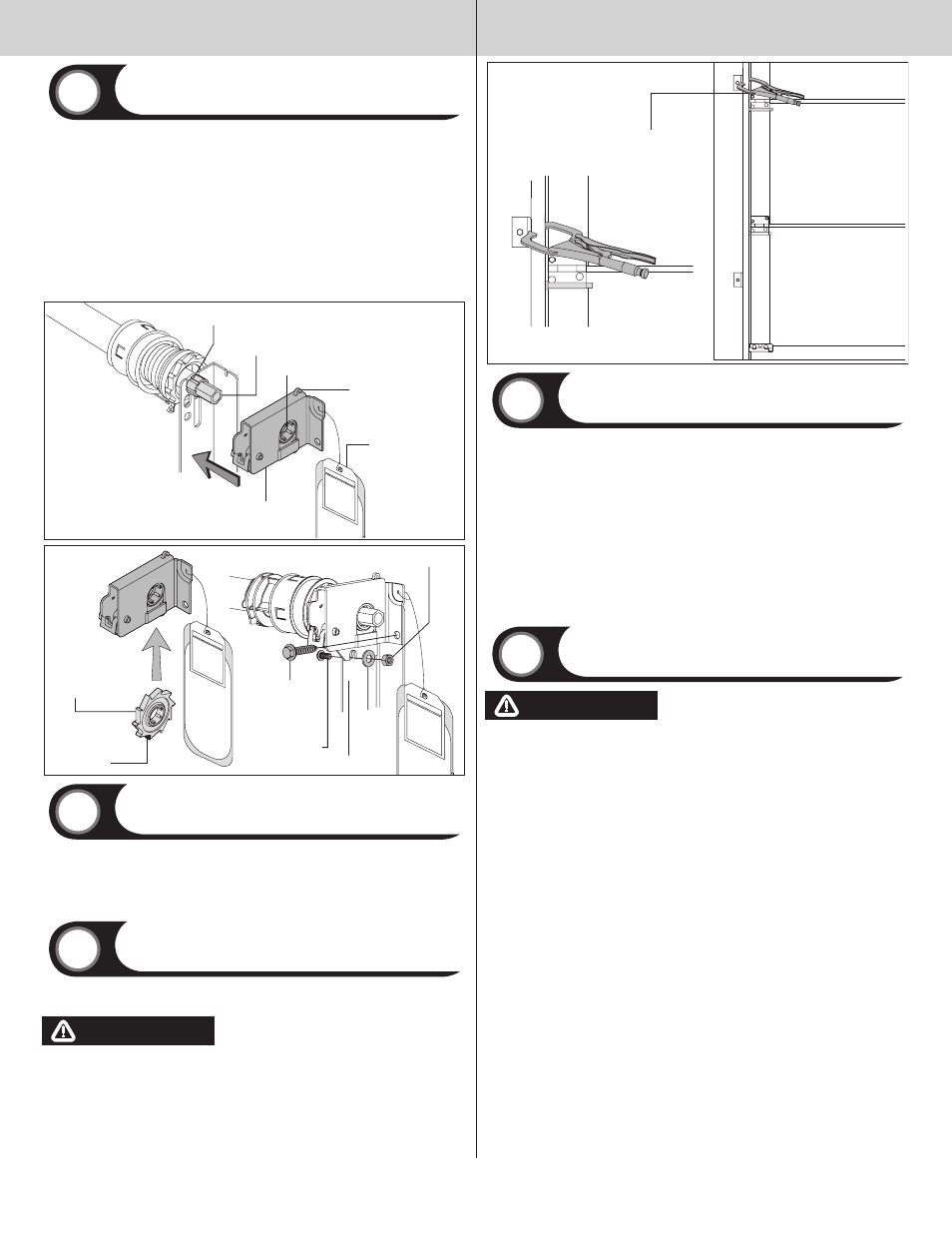

End Brackets

Tools: Power drill, 7/16” Socket driver, 1/2” Wrench, Step ladder

21

IMPORTANT: WARnInG TAGS MuST BE SECuRElY ATTACHED TO BOTH EnD BRACKETS.

End brackets are right and left hand. You can identify the right hand end bracket by the discon-

nect cable guide hole in the top of the bracket.

Beginning with the right hand side, slide the end bracket onto the winding shaft so that the

splines in the ratchet wheel fit onto the winding shaft grooves.

Attach the end bracket to the flag angle using (1) 5/16”-18 x 3/4” carriage bolt, (1) 5/16”

washer and (1) 5/16”-18 hex nut; then secure it to the jamb using (1) 5/16” x 1-5/8” lag screw.

Repeat for left hand end bracket

NOTE: If ratchet wheel falls out of end bracket, refer to illustration for proper insertion orienta-

tion.

NOTE: On single spring applications, no ratchet wheel is required on the left hand side.

Grooves

Warning tag

Disconnect cable

guide hole

Splines

Winding

shaft

Right end bracket

Ratchet wheel

(teeth pointing

upwards)

Black tooth

5/16” x 1-5/8”

Lag screw

5/16” -18 x 3/4”

Carriage bolt

5/16”

Washer

Flag angle

5/16” Hex nut

securing Center Bearing Bracket Assembly

Tools: Power drill, 3/16” Drill bit, 7/16” Socket driver, Step ladder, Level

22

IMPORTANT: TORQuEMASTER

®

SPRInG TuBE MuST BE lEVEl BEfORE SECuRInG CEnTER

BEARInG BRACKET ASSEMBlY TO HEADER.

To locate the center bearing bracket assembly, mark the header halfway between the flag angles

and level the TorqueMaster

®

spring tube. Drill 3/16” pilot holes into header for the lag screws.

fasten the center bearing bracket assembly to the header using (2) 5/16” x 1-5/8” lag screws.

securing Door for spring Winding

Tools: Vice Clamps

23

Place vice clamps onto both vertical tracks just above the third roller. This is to prevent the

garage door from rising while winding counterbalance springs.

WARNING

WARNING

fAILuRE TO PLACE vICE CLAMPs ONTO vERTICAL TRACk CAN ALLOW DOOR

TO RAIsE AND CAusE sEvERE OR fATAL INjuRy.

Vice clamps above third

roller on both sides of door

Bottom section

Vice clamps attached to inner

and outer rail of vertical track

Cable Adjustments

Tools: Locking pliers, Flat tip screwdriver, Step ladder, Tape measure,

Pliers/ Wire cutters

24

Starting on the right side, adjust the cable drum assembly by rotating the drum until the set

screw faces directly away from the header. TorqueMaster

®

spring tube cam peak should be

pointing straight up.

loosen the set screw no more than 1/2 turn. Ensure counterbalance cable is aligned and seated

in the first and second grooves of the cable drum and pull on the end of the cable to remove all

cable slack.

Snug the set screw, and then tighten an additional 1-1/2 turns. Measure approximately 6” of

cable and cut off excess cable. Insert end of cable in hole of cable drum. Repeat for left hand

cable drum assembly.

IMPORTANT: EnSuRE THE CABlE IS AlIGnED AnD SEATED In THE fIRST AnD SECOnD

GROOVES Of THE CABlE DRuM PRIOR TO WInDInG SPRInGS.

NOTE: Illustration shows the right hand TorqueMaster

®

Plus cable drum assembly, left hand

cable drum assembly is symmetrically opposite.

Winding springs

Tools: Ratchet wrench, 5/8” Socket, 3” Socket extension, Pliers/ Wire

cutters, Flat tip screwdriver, Step ladder

25

WARNING

WARNING

IT Is RECOMMENDED ThAT LEAThER GLOvEs BE WORN WhILE WINDING ThE

TORQuEMAsTER

®

PLus sPRINGs. fAILuRE TO WEAR GLOvEs MAy CAusE

INjuRy TO hANDs.

Double check to ensure the counterbalance cable is aligned in the first and second grooves of

the cable drum (see step, Cable Adjustments). There are two methods for counting the spring

turns as you wind. One method is to identify the black tooth on the ratchet wheel inside of the

end bracket. When the wheel makes one revolution and the tooth returns to its starting point,

one turn has been made. The other method is to make a mark on the winding shaft (or socket)

and end bracket, and count your turns in this manner.

Starting on the right hand side, turn the pawl knob on the end bracket to the upper position.

using a ratchet wrench with a 5/8” (16mm) socket (

NOTE: A 3” (76mm) extension is also

recommended for added clearance from the horizontal angle), wind the spring by rotating the

winding shaft counter clockwise, while watching either the black tooth on the ratchet wheel or

the mark on the winding shaft.

IMPORTANT: PAWl KnOB MuST BE In uPPER POSITIOn TO ADD/ REMOVE REQuIRED nuMBER

Of SPRInG TuRnS.

After 2-3 turns, remove the ratchet wrench and adjust the cable on the left side. Ensure

counterbalance cables are in the first and second grooves of the cable drums in step, Cable

Adjustments.

NOTE: Single spring applications require no spring winding on the left hand side, but cable

tension needs to be adjusted.

IMPORTANT: COunTERBAlAnCE CABlE TEnSIOn MuST BE EQuAl On BOTH SIDES PRIOR TO

fullY WInDInG SPRInGS.

see the spring turn chart for the required number of turns:

for single spring applications:

Return to the right hand end bracket and continue winding the spring to the required number of

turns for your door. Place pawl knob in lower position.

for double spring applications:

Either use the black tooth on the ratchet wheel for winding reference or place a mark on the

winding shaft and end bracket. Place the ratchet wrench with 5/8” socket onto the left hand

winding shaft end. To wind the spring, rotate the winding shaft clockwise, while watching the

5

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com