Warning, Attach horizontal tracks to q.i. flag angles, Attach horizontal tracks to f.a. flag angles – Wayne-Dalton TORQUE MASTER PLUS 9400 User Manual

Page 4: Adjusting top brackets, Torquemaster, Spring tube, Center bearing bracket, Cable drum assemblies

NOTE: When attaching operator bracket to top section with u-bar, apply additional pressure to

thread into the u-bar.

(2) #12 x 1/2”

Phillips head screws

(5) 1/4”- 14 x 5/8”

Self-tapping screws

Top section

Tools: Hammer, Step ladder, Tape measure

14

Place the top section in the opening. Temporarily secure the top section by driving a nail in the

header near the center of the door and bending it over the top section. now, flip up the hinge

leaves, hold tight against section, and fasten center hinges first and end hinges last (refer

to step, Stacking Sections). Vertical track alignment is critical. Position flag angle between

1-11/16” (43 mm) to 1-3/4” (44 mm) from the edge of the door; tighten the bottom lag screw.

flag angles must be parallel to the door sections. Repeat for other side.

IMPORTANT: THE DIMEnSIOn BETWEEn THE flAG AnGlES MuST BE DOOR WIDTH PluS

3-3/8” (86MM) TO 3-1/2” (89 MM) fOR SMOOTH, SAfE DOOR OPERATIOn.

for Q.I. track:

Complete the vertical track installation by securing the jamb bracket(s) and tightening the other

lag screws. Repeat for other side.

for f.A. track:

Complete the vertical track installation by securing the jamb bracket(s) and tightening the other

lag screws. Push the vertical track against the rollers so that the rollers are touching the deepest

part of the curved side of the track; tighten all the track bolts and nuts. Repeat for other side.

Attach horizontal Tracks to Q.I. flag Angles

Tools: Ratchet wrench, 9/16” Socket, 9/16” Wrench, level, Step ladder

15

NOTE: If you have Q.I. flag angles, complete this step.

To install horizontal track, place the curved end over the top roller of the top section. Align key

slot of the horizontal track with the Q.I. tab of the flag angle. Push curved portion of horizontal

track down to lock in place.

WARNING

WARNING

DO NOT RAIsE DOOR uNTIL hORIzONTAL TRACks ARE sECuRED AT REAR, As

OuTLINED IN sTEP, REAR suPPORT, OR DOOR COuLD fALL fROM OvERhEAD

POsITION CAusING sEvERE OR fATAL INjuRy.

level the horizontal track assembly and bolt the horizontal angle to the first encountered slot in

the flag angle using (1) 3/8”-16 x 3/4” truss head bolt and (1) 3/8”-16 hex nut. Repeat for other

side.

Remove the nail that was temporarily holding the top section in place, installed in step, Top

Section.

IMPORTANT: fAIluRE TO REMOVE nAIl BEfORE ATTEMPTInG TO RAISE DOOR COulD CAuSE

PERMAnEnT DAMAGE TO TOP SECTIOn.

NOTE: If an idrive

®

opener will be installed, position horizontal tracks slightly above level.

Attach horizontal Tracks to f.A. flag Angles

Tools: Ratchet wrench, 7/16” Socket, 9/16” Socket, 9/16” Wrench,

level, Step ladder

16

NOTE: If you have f.A. flag angles, complete this step.

To install horizontal track, place the curved end over the top roller of the top section. Align the

bottom of the horizontal track with the top of the vertical track. If you have Q.I. horizontal track,

tighten the horizontal track to the flag angle with a stud plate and (2) 1/4”-20 flange hex nuts. If

you have universal horizontal track, tighten the horizontal track to the flag angle with (2) 1/4”-20

x 9/16” track bolts and (2) 1/4”-20 flange hex nuts.

WARNING

WARNING

DO NOT RAIsE DOOR uNTIL hORIzONTAL TRACks ARE sECuRED AT REAR, As

OuTLINED IN sTEP, REAR suPPORT, OR DOOR COuLD fALL fROM OvERhEAD

POsITION CAusING sEvERE OR fATAL INjuRy.

level the horizontal track assembly and bolt the horizontal angle to the first encountered slot in

the flag angle using (1) 3/8”-16 x 3/4” truss head bolt and (1) 3/8”-16 hex nut. Repeat for other

side.

Remove the nail that was temporarily holding the top section in place, installed in step, Top

Section.

IMPORTANT: fAIluRE TO REMOVE nAIl BEfORE ATTEMPTInG TO RAISE DOOR COulD CAuSE

PERMAnEnT DAMAGE TO TOP SECTIOn.

NOTE: If an idrive

®

opener will be installed, position horizontal tracks slightly above level.

Adjusting Top Brackets

Tools: 7/16” Wrench, Step ladder

17

With horizontal tracks installed, you can now adjust the top brackets. Vertically align the top sec-

tion of the door with the lower sections. Once aligned, position the top bracket slide, out against

the horizontal track. Maintaining the slide’s position, tighten the (2) 1/4”-20 flange hex nuts to

secure the top bracket slide to the top bracket base. Repeat for other side.

TorqueMaster

®

spring Tube

Tools: None

18

TorqueMaster

®

springs come lubricated and pre-assembled inside the TorqueMaster

®

spring

tube. To prepare for install, lay the TorqueMaster

®

spring tube assembly on the floor, inside

garage, in front of the door, and with the labeled end to the left.

Center Bearing Bracket

Tools: None

19

NOTE: If you are installing the idrive

®

opener with your garage door, skip this step and go to

your idrive

®

Installation Instructions and Owner’s Manual. After completing the steps up to and

including, Drum Wrap Installation of your idrive

®

Installation Instructions and Owner’s Manual

continue with Step, Rear Support, of this door Installation Instructions and Owner’s Manual.

NOTE: If you are not installing the idrive

®

opener on your garage door, you must install the cen-

ter bearing bracket assembly. follow these instructions for non-idrive

®

operated garage doors.

Being cam shaped, the center bearing bracket assembly only fits one way. Slide the center bear-

ing bracket assembly towards the center of the TorqueMaster

®

spring tube, from the right side.

Cable Drum Assemblies

Tools: Tape measure, Step ladder

20

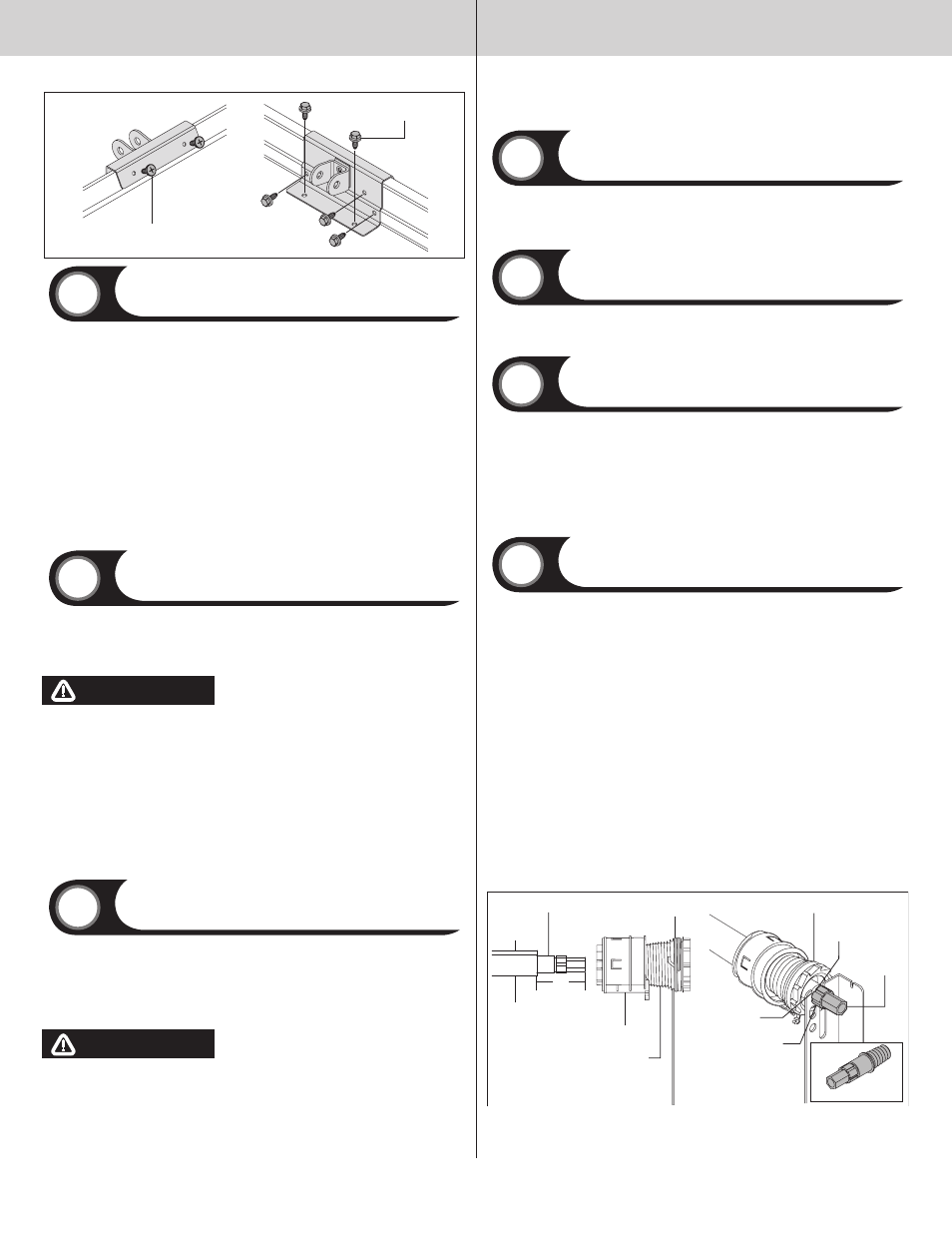

Shake the TorqueMaster

®

spring tube assembly gently to extend the winding shafts out about 5”

on each side. for single spring applications, there will be no left hand spring in the TorqueMas-

ter

®

spring tube assembly. lift the TorqueMaster

®

spring tube assembly and rest it on top of the

flag angles.

NOTE: Cable drum assemblies are marked right and left hand and consist of a cable drum

and drum wrap. Cable drums and TorqueMaster

®

spring tube assembly are cam shaped to fit

together only one way.

Starting on the right hand side, slide the drum wrap over to access the counterbalance cable.

Pre-wrap the cable drum with the counterbalance cable 1-1/2 wraps as shown.

Position the TorqueMaster

®

spring tube assembly so the can peak is pointing straight up. Slide

the cable drum over the winding shaft until the cable drum seats against the TorqueMaster

®

spring tube assembly.

The winding shaft must extend past the cable drum far enough to expose the splines and the

grooves. Align the winding shaft grooves with the round notch in the flag angle.

for double spring applications: Repeat for left hand side.

for single spring applications: Pre-wrap the left hand cable drum with counterbalance cable

1-1/2 wraps and insert the loose winding shaft into the cable drum prior to sliding the cable

drum over the TorqueMaster

®

spring tube assembly.

NOTE: On single spring applications, take care in handling the loose winding shaft (left side) so

that it does not slide back into the TorqueMaster

®

spring tube assembly.

Torquemaster

®

spring

tube assembly

Cam peak

straight

Winding shaft

Counterbalance cable

1-1/2 wraps

Drum wrap

Grooves

Cable drum

Splines

Round notch

Winding

shaft

Right cable

drum

5”

Loose winding shaft

4

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com