General specifi cations, Warning–professional service required, Table 2 – burner specifi cations – Weil-McLain NX User Manual

Page 5: Table 3 – air tube combination (atc) codes

WM 550-141-996/1105

Page 5

RWB 6104WMNX R1005

General Specifi cations

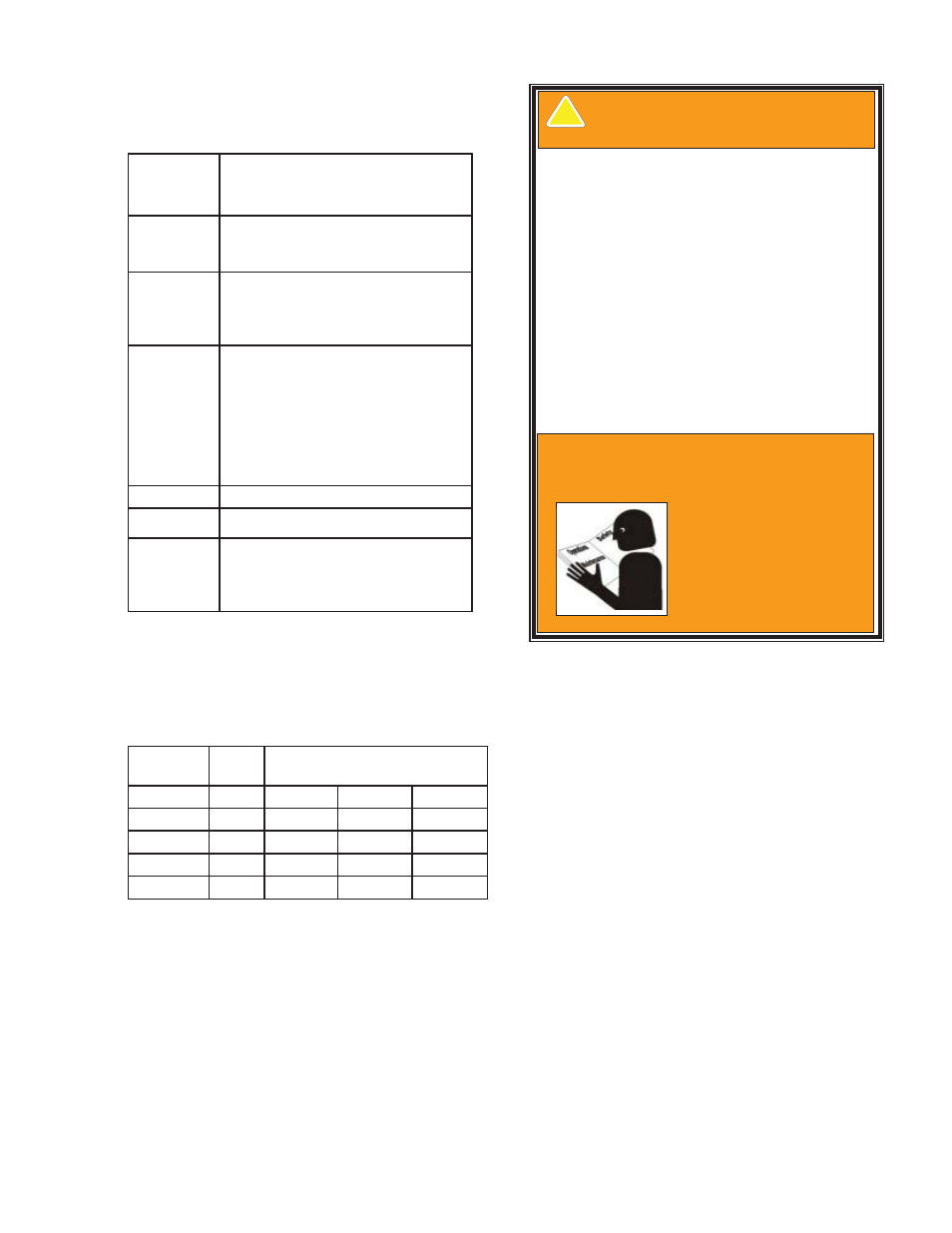

Table 2 – Burner Specifi cations

Capacity

LB & LC

Firing rate 0.40 – 1.35 GPH

Input 56,000 – 189,000 Btu

LD & LF

Firing rate 1.10 - 1.75 GPH

Input 154,000 – 245,000 Btu/h

Fuels

U. S No. 1 or No. 2 heating oil only

...........(ASTM D396)

Canada No. 1 stove oil or No. 2

.........furnace oil only

Electrical

Power supply 120 volts AC, 60 Hz,

.............single phase

Operating load 5.8 Amps max

Motor 1/7 hp, 3450 rpm, NEMA 48M

frame PSC rotation CCW

when facing shaft end

Ignition Continuous duty solid-state

igniter

Fuel pump

Outlet pressure ...... Note 1

Air tube

ATC code .......See Table 3

Dimen-

sions

(with

cover)

Height (maximum) 12-1/2 inches

Width (maximum) 15 inches

Depth ............ 9-1/4 inches

Air tube diameter 3-1/4 inches

Note 1. See appliance manufacturer’s burner specifi ca-

tions for recommended outlet pressure.

Table 3 – Air Tube Combination (ATC)

codes

Firing rate

(gph)

Head

ATC codes for usable air tube

lengths:

(min-max)

5”

7”

9”

0.40-1.35

9-Slot

NX50LB

NX70LB

NX90LB

0.40-1.35

6-Slot

NX50LC

NX70LC

NX90LC

1.10-1.75

9-Slot

NX50LD

NX70LD

NX90LD

1.10-1.75

6-Slot

NX50LF

NX70LF

NX90LF

Certifi cations/approvals

Underwriters Laboratories has certifi ed this burner

to comply with ANSI/UL 296 and has listed it for

use with #1 or #2 fuel oil as specifi ed in ASTM

D396. Low sulfur #1 and #2 fuel oils reduce heat

exchanger deposits with all burners compared to

the standard fuels. Reduced deposits extend the

service interval for cleaning and improve the effi -

ciency of the appliance over time. Low sulfur fuels

reduce particulate and oxides of nitrogen emis-

sions as well. The Oilheat Manufacturers’ Associa-

tion recommends these fuels as the preferred fuels

for this burner.

•

Warning–Professional

Service Required

This equipment must be installed, adjusted and put into

operation only by a qualified individual or service agency

that is:

x Licensed or certified to install and provide technical

service to oil heating systems.

x Experienced with all applicable codes, standards and

ordinances

x Responsible for the correct installation and

commission of this equipment

x Skilled in the adjustment of oil burners using

combustion test instruments.

The installation must strictly comply with all applicable

codes, authorities having jurisdiction and the latest

revision of the National Fire Protection Association

Standard for the Installation of Oil-Burning Equipment,

NFPA 31 (or CSA B139 and B140 in Canada).

Regulation by these authorities take precedence over the

general instructions provided in this installation manual.

S105

Read and understand the manual

supplied with this equipment. Incorrect

installation, adjustment, and use of

this burner may result in

severe personal injury

death, or substantial

property damage from

fire, carbon monoxide

poisoning, soot or

explosion.

!

General Specifi cations