Weil-McLain NX User Manual

Page 13

WM 550-141-996/1105

Page 13

RWB 6104WMNX R1005

Chimney Vent Systems: Install the burner cover

and repeat Steps 2 and 4 above. If CO2 increas-

es (O2 decreases), remove the cover and adjust

the air setting so the CO2 (O2) with the cover

installed meets the requirements of Step 3.

Direct Vent Systems with Outside Air Ducted to

Burner: Install the burner cover.

Start and stop the burner several times to ensure

satisfactory operation. Test the primary control

and all other appliance safety controls to verify

that they function according to the manufactur-

er’s specifi cations.

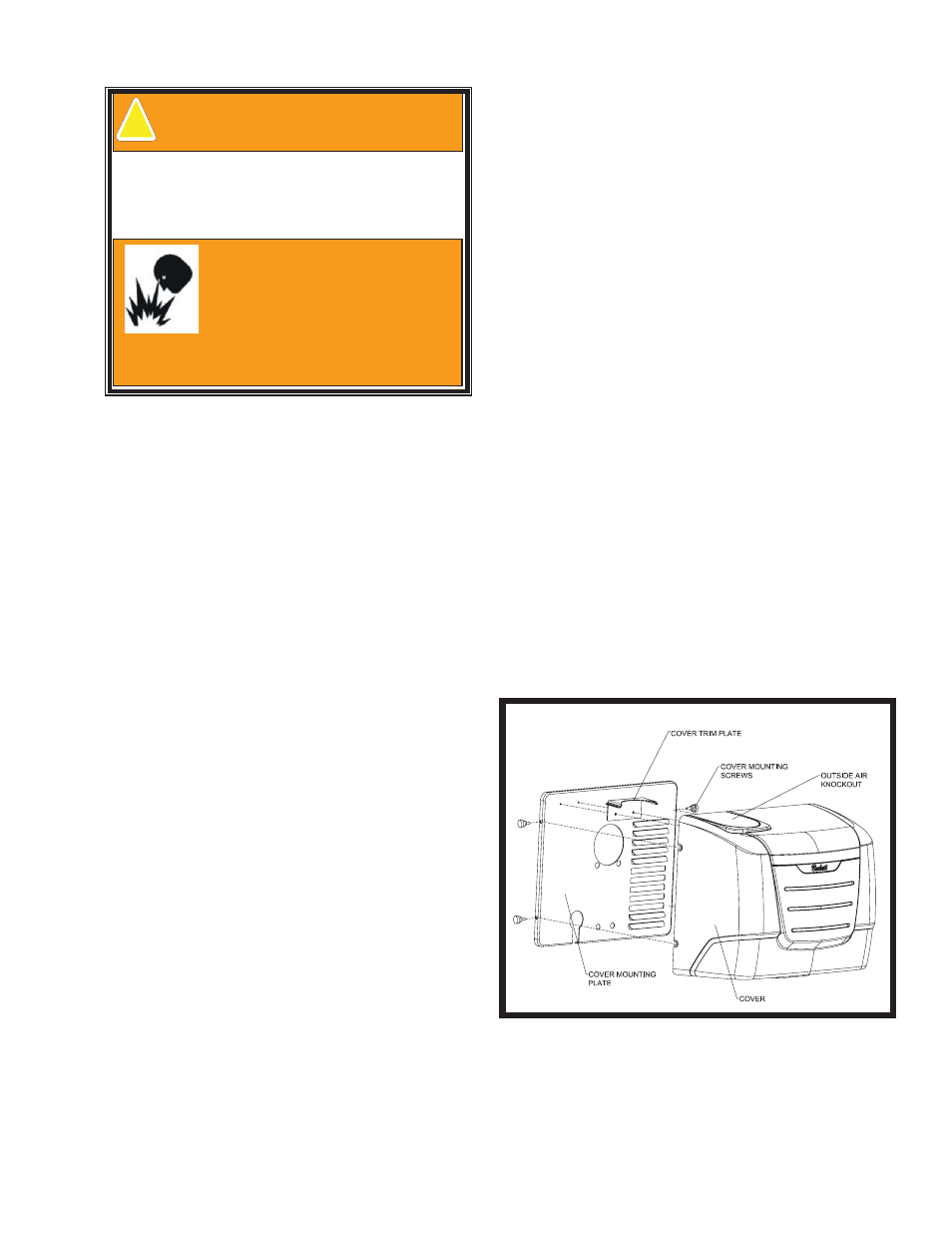

Cover Installation

Install the cover mounting screws in the cover

mounting plate.

Install the cover over the mounting plate while

aligning the side slots with the installed cover

mounting screws.

Direct Vent specifi ed burners include an opening

on the top of the cover for an outside air intake.

4.

5.

6.

•

1.

2.

3.

Figure 6. – Burner Cover

SK9804A

Start the Burner

Warning–Check for Excess

Fuel Accumulation.

Do not attempt to start the burner when excess fuel or

vapor has accumulated in the appliance. Starting the burner

under these conditions could result in a puffback of hot

combustion gases, high smoke levels, or otherwise

hazardous operation.

Could cause death, personal

injury and/or substantial

property damage due to

equipment malfunction, heavy

smoke, soot blockage, hot gas

puff-back, fire and asphyxiation

hazard

.

S112

!

Step

1:

Adjust the head/air until a trace of smoke

is achieved. This can be accomplished by turn-

ing the screw on the head/air adjustment plate

assembly to increase air (CCW) or decrease air

(CW).

Step 2:

At the trace of smoke level, measure the

CO2 (or O2) . This is the vital reference point

for further adjustments. Example: 13.5% CO2

(2.6% O2)

Step 3:

Increase the air to reduce the CO2 by 1.5

to 2 percentage points. (O2 will be increased by

approximately 2.0 to 2.7 percentage points.) Ex-

ample: Reduce CO2 from 13.5% to 11.5% (2.6%

to 5.3% O2).

Step 4:

Recheck smoke level. It should be Zero.

This procedure provides a margin of

reserve air to accommodate variable

conditions.

If the draft level has changed, recheck the

smoke and CO2 levels and readjust

burner, if necessary.

Step 5:

Once the combustion has been set, tight-

en the lower acorn nut and splined nut on the air

adjustment assembly. See Figure 5.

•

•

Set Combustion with Test Instruments

Allow the burner to run for approximately 5 to 10

minutes.

Set the stack draft between -0.01” to

-0.02” w.c. for chimney vent applications. No

draft adjustment required for direct venting.

Follow these fi ve steps to properly adjust the

burner:

•

1.

2.

3.