Optional installations, Trolley arm configuration – Wayne-Dalton TORQUEMASTER 9600 User Manual

Page 8

or TorqueMaster® Plus operation problems.

Close the door and place vice clamps onto both vertical tracks just above the third roller. This is

to prevent the garage door from raising while adjusting the counterbalance spring(s).

IMPORTANT: TO ADjuST SPRInGS, OnlY ADD OR REMOVE A MAxIMuM Of 3/10 Of A TuRn

(THREE TEETH On THE RATCHET WHEEl) AT A TIME. BOTH SIDES nEED TO BE ADjuSTED

EQuAllY On DOuBlE SPRInG DOORS.

Add spring tension: The ratchet wheel is made of 10 teeth. To add spring tension, ensure the

ratchet and socket is set so that it will tighten counter clockwise on the right hand side and

clockwise on the left hand side. Place the ratchet wrench with 5/8” socket and 3” socket exten-

sion onto the winding shaft, pull down to add 3/10 of a turn. Watch as three teeth of the ratchet

wheel pass over the pawl, creating three “clicks”.

Remove spring tension: To remove spring tension, place a regular 5/8” wrench onto the winding

shaft. Pull down on the wrench to relieve pressure between the pawl and the ratchet wheel.

Push in on the pawl to allow the three ratchet wheel teeth to pass by the pawl, as you carefully

allow the wrench to be rotated upward by the spring tension, release the pawl to allow it to

engage with the ratchet wheel.

IMPORTANT: BE PREPARED TO HOlD THE full TEnSIOn Of THE SPRInG.

IMPORTANT: DO nOT ADD OR REMOVE MORE THAn 1 SPRInG TuRnS (1 SPRInG TuRn

EQuAlS 10 TEETH On RATCHET WHEEl) fROM THE RECOMMEnDED nuMBER Of TuRnS

SHOWn On THE SPRInG TuRn CHART.

If the door still does not operate easily, lower the door into the closed position, unwind spring(s)

completely, and recheck the following items:

1.) Check the door for level.

2.) Check the TorqueMaster® spring tube and flag angles for level and plumb.

3.) Check the distance between the flag angles, which must be door width plus 3-3/8” to

3-1/2”.

4.) Check the counterbalance cables for equal tension; adjust if necessary.

5.) Rewind the spring(s).

6.) Make sure door isn’t rubbing on jambs.

NOTE: If an idrive® opener was installed and you have completed this step, refer to the idrive®

Installation Instructions and Owner’s Manual to complete your idrive® installation.

oPTIonal InsTallaTIons

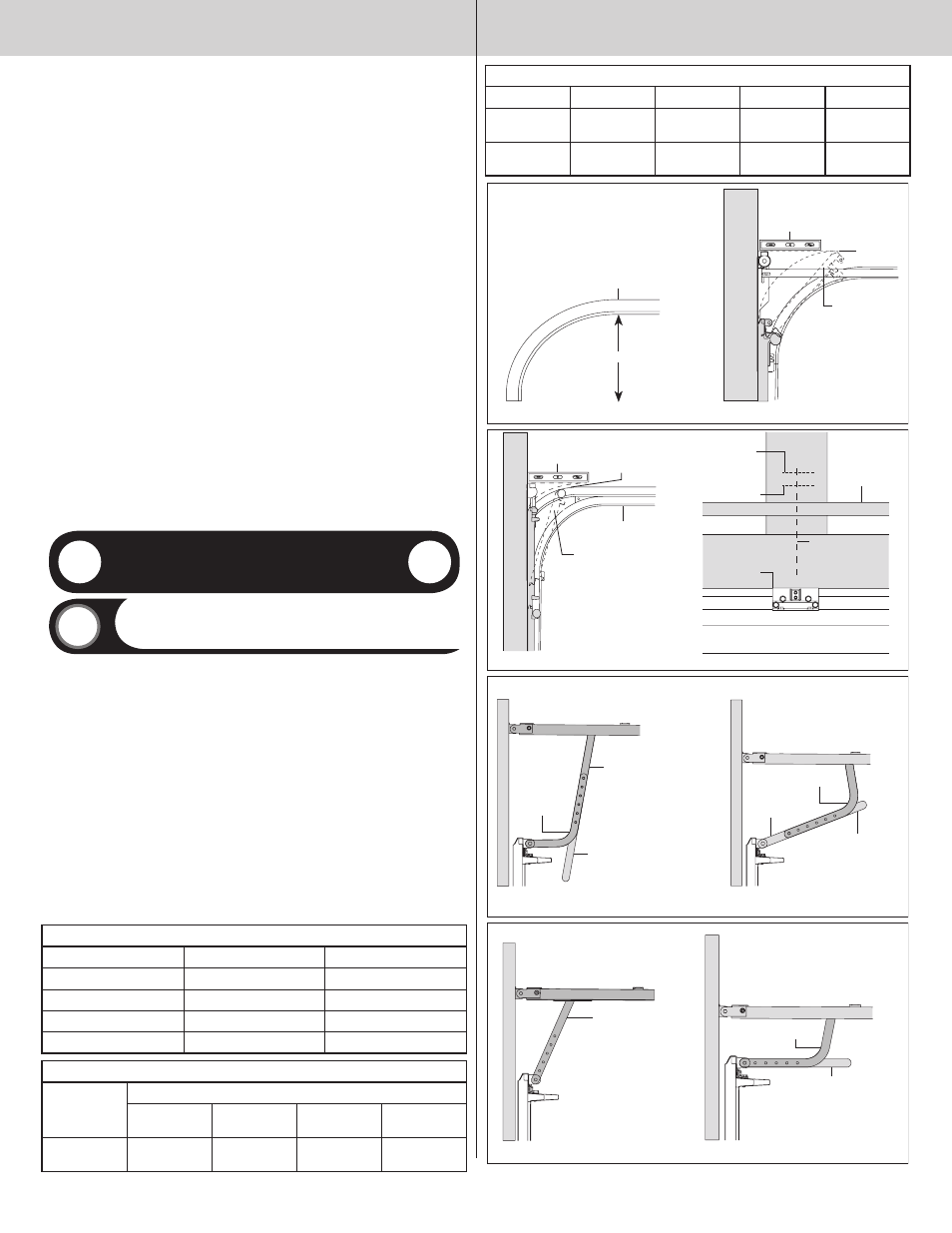

Trolley Arm Configuration

Tools: Tape measure, Level

Measure the curved ends of the horizontal track to determine if you have a 12” or 15” radius

horizontal track, as shown in fIG 1; if you have a low headroom door skip this step. Determine

center line of the door. Mark vertical line at this point on the header, as shown in fIG 4. Raise

the door slightly until the top section reaches the highest point of travel (high arc), as shown in

fIG 2 and fIG 3 for low headroom. using a level, mark this high arc point on the header where it

intersects the vertical center line, as shown in fIG 4. Hold the wall bracket’s bottom edge 1/2” -

1” (room permitting) above the high arc line and centered on the vertical center line, as shown in

fIG 4. Mark the wall bracket’s mounting holes on the header wall and then refer to your garage

door operator manual for pre-drilling and securing the wall bracket to header.

using the operator hook-up charts, refer to referenced illustrations for correct arm hook-up from

trolley to operator bracket. for low headroom, refer to operator hook-up chart for low headroom.

note: Refer to your operator manual for specific details on how to assembly the curved and

straight arm, as shown in fIG 5 and fIG 6, and fIG 7 and fIG 8 for low headroom.

NOTE: Depending on your setup, you may or may not have to cut straight arm to accomplish

trolley settings.

Align hole in the appropriate arm with holes in operator bracket tabs, as shown in step, Trolley

Arm Hookup. Insert 5/16” x 1-1/4” clevis pin, making sure hole in clevis pin is outside of second

tab of operator bracket. Insert cotter pin into clevis pin hole and spread hairpin cotter to ensure

it will secure assembly.

OPERATOR HOOK-uP CHART,STAnDARD lIfT fOR 12” AnD 15” RADIuS

OPERATOR MODElS

TYPE Of ARM BEInG uSED

REf. IlluSTRATIOnS

QuAnTuM/ClASSIC

CuRVED / STRAIGHT

fIG 6

lInEAR

STRAIGHT / CuRVED

fIG 5

lIfTMASTER (SEARS)

CuRVED / STRAIGHT

fIG 6

GEnIE

CuRVED / STRAIGHT

fIG 6

OPERATOR HOOK-uP CHART fOR lOW HEADROOM

OPERATOR

MODElS

TYPE Of ARM BEInG uSED

PREfERRED

HOOKuP

REf. IlluSTRA-

TIOnS

OPTIOnAl

HOOK-uP

REf. IlluSTRA-

TIOnS

QuAnTuM /

ClSSSIC

CuRVED /

STRAIGHT

fIG. 8

STRAIGHT

fIG. 7

OPERATOR HOOK-uP CHART fOR lOW HEADROOM

lInEAR

STRAIGHT

fIG. 7

n/A

n/A

lIfTMASTER

(SEARS)

CuRVED /

STRAIGHT

fIG. 8

STRAIGHT

fIG. 7

GEnIE

CuRVED /

STRAIGHT

fIG. 8

STRAIGHT

fIG. 7

FIG 1

12” or 15”

FIG 2

Horizontal

track

Level

High arc

Top section

High arc

FIG 4

FIG 3

TorqueMaster

®

counterbalance

Vertical

center line

From step

Typical 1/2”-1”

above high arc

High arc line

Header

Top section

Low headroom track

Level

Cut straight arm to

accomplish trolley

setting

FIG 6

FIG 5

Curved arm

Curved arm

Cut straight arm to

accomplish trolley

setting

Straight arm

Straight arm

Curved arm

Straight arm

FIG 8

FIG 7

Cut straight arm to

accomplish trolley setting

8

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com