Troubleshooting and solutions, Gm 2000 eac - en – Wagner SprayTech GM 2000 EACF User Manual

Page 25

6.

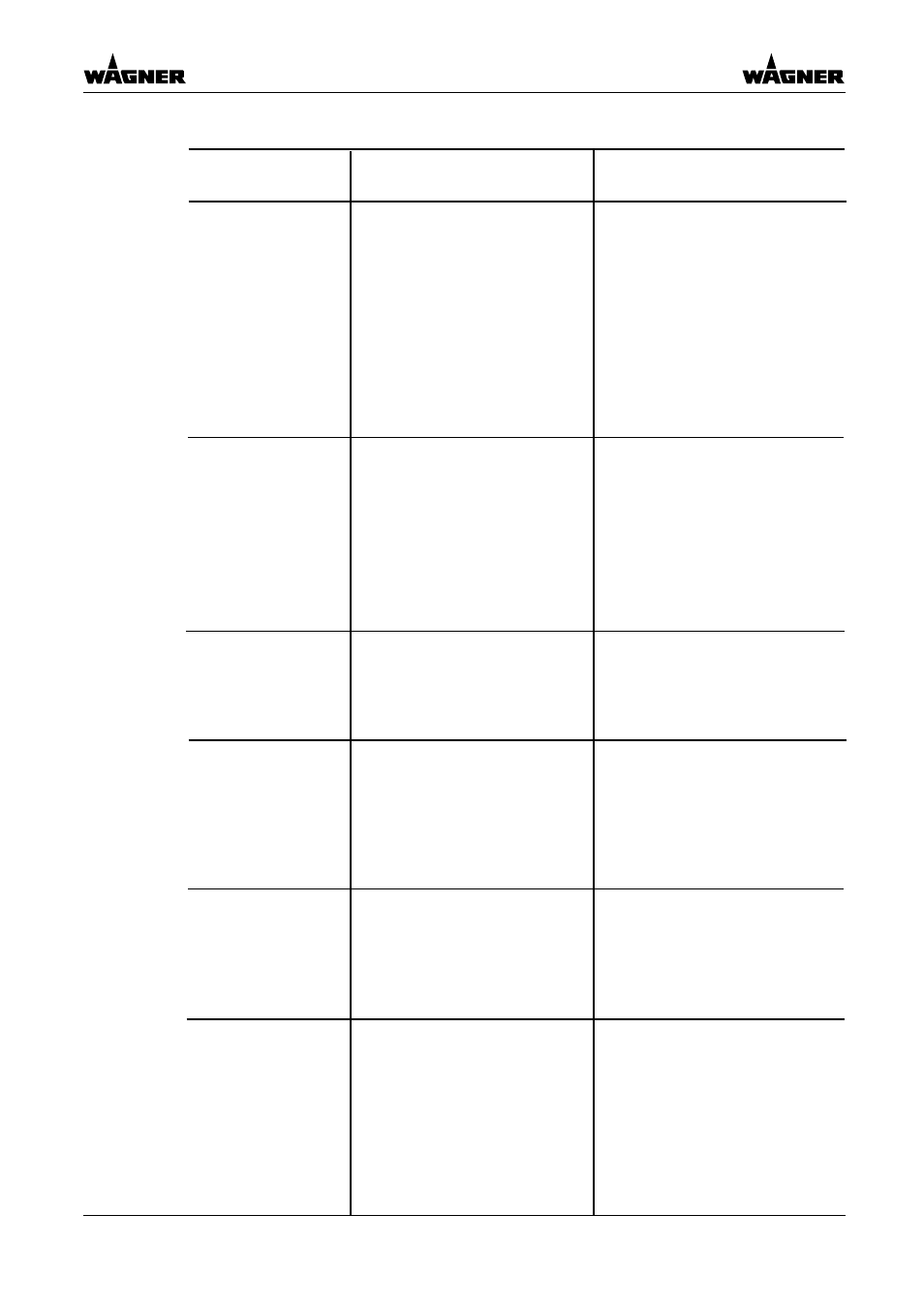

TROUBLE SHOOTING AND SOLUTIONS

GM 2000 EAC - EN

6.1

Problem

Insufficient material

output

Poor spray pattern

Leaking air valve

Poor wrap round or

electrostatic effect

Back spraying

No electrostatic ef-

fect

(no wrap around)

Cause

• Tip too small

• Material pressure too low

• Gun filter or high-pressure

filter in pump blocked

• AirCoat tip (round) clogged

• Wrongly adjusted atomizing

air

• Tip too large

• Material pressure too low

• Material viscosity too high

• Damaged seals on the valve

rod

• Poor earth

• Paint conductivity too high /

resistance paint too high

• Spraying pressure too high

• No earth

• Distance between spray gun

and workpiece too large.

• High voltage switched off ?

• High voltage failure

Solution

• Select larger tip (see chapter

7.1 and 7.2)

• Increase material pressure

• Clean or exchange filter

• Clean tip (see chapter 4.4,

4.8 and 4.9)

• Readjust the atomizing air

• Select smaller tip (see chap-

ter 7.1 and 7.2)

• Increase material pressure

• Thin material acc. to manu-

facturer's instruction.

• Exchange seals (see chapter

5.4 and 5.5)

• Check earth of object

• Check resistance of paint

(see chapter 2.4)

• Adjust spraying pressure

• Check earth. (see chapter

3.2)

• Reduce distance between

spray gun and workpiece.

• Switch on high voltage.

• Repair failure acc. to opera-

ting instructions of control

unit.