2 aircoat round jet process, 3 aircoat flat jet process, Gm 2000 eac - en – Wagner SprayTech GM 2000 EACF User Manual

Page 13

2.3.2

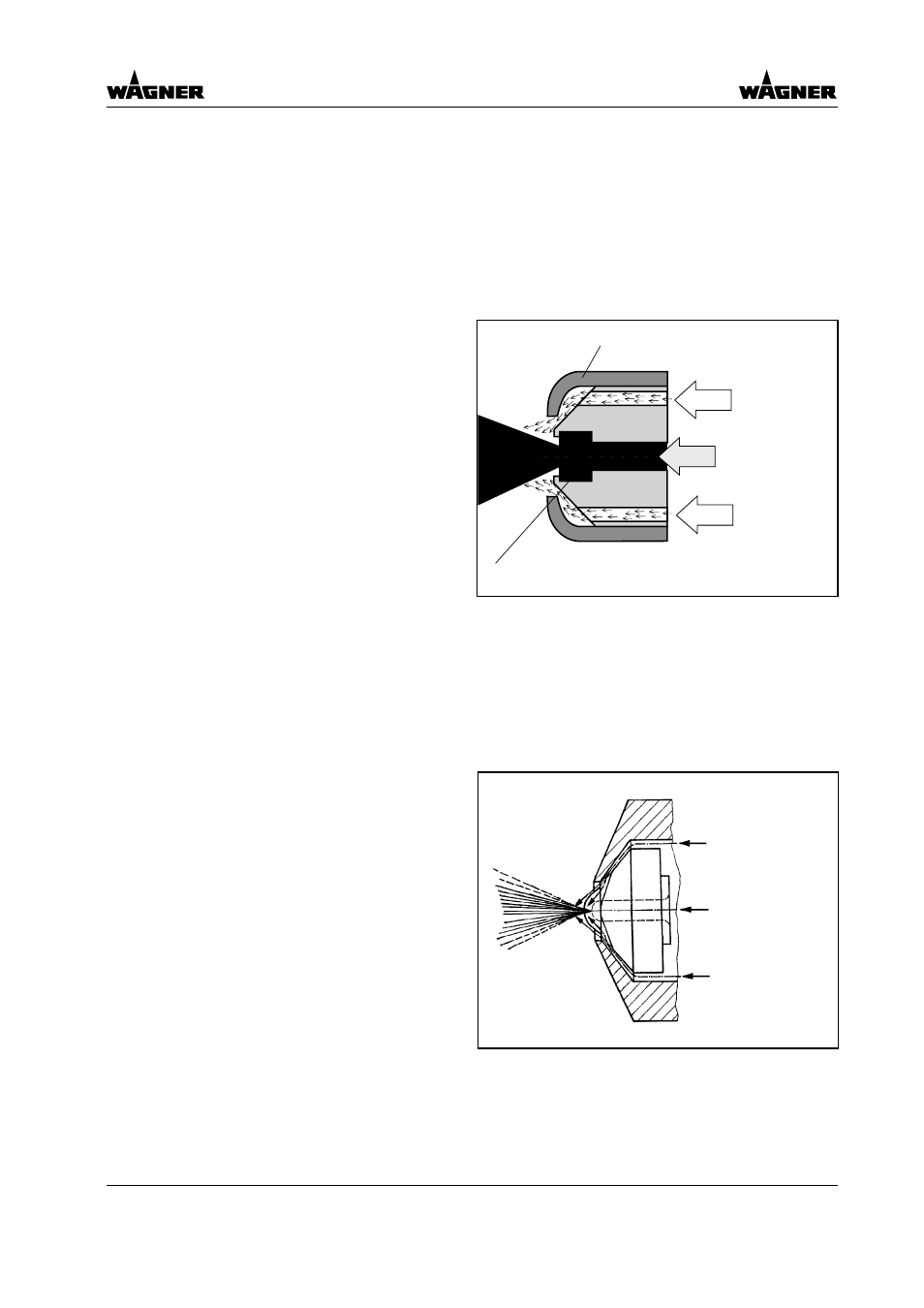

AirCoat round jet process

In the AirCoat process, high pressure of 30 to 150 bar is used to atomize the material.

The AirCoat air at 0 to 2.5 bar produces a soft jet, which largely eliminates the problem

of overlapping boundaries. The spray jet can be adjusted by turning the nozzle nut.

The multi-channel swirl nozzle produces fine paint particles, while at the same time

reducing their forwards speed and swirling them to produce a rotating motion. The

result is a soft, extremely well atomized spraying cloud.

Advantages of AirCoat

●

High painting capacity

●

Low fogging tendency

●

Good finish

●

High- viscosity paints can easily

be applied

2.3.3

AirCoat flat jet process

In the AirCoat process, high pressure of 30 to 150 bar is used to atomize the material.

The AirCoat air at 0 to 2.5 bar produces a soft jet, which largely eliminates the problem

of overlapping boundaries.

Advantages of AirCoat

●

High painting capacity

●

Low fogging tendency

●

Good finish

●

High- viscosity paints can easily

be applied

GM 2000 EAC - EN

2.3

AirCoat air

AirCoat air

Material

Multi-channel swirl nozzle

Nozzle nut

AirCoat air

AirCoat air

Material