Step 5: cable drum installation, Step 6: bottom bracket lifting cables – Wayne-Dalton IDRIVE 3982 User Manual

Page 9

9

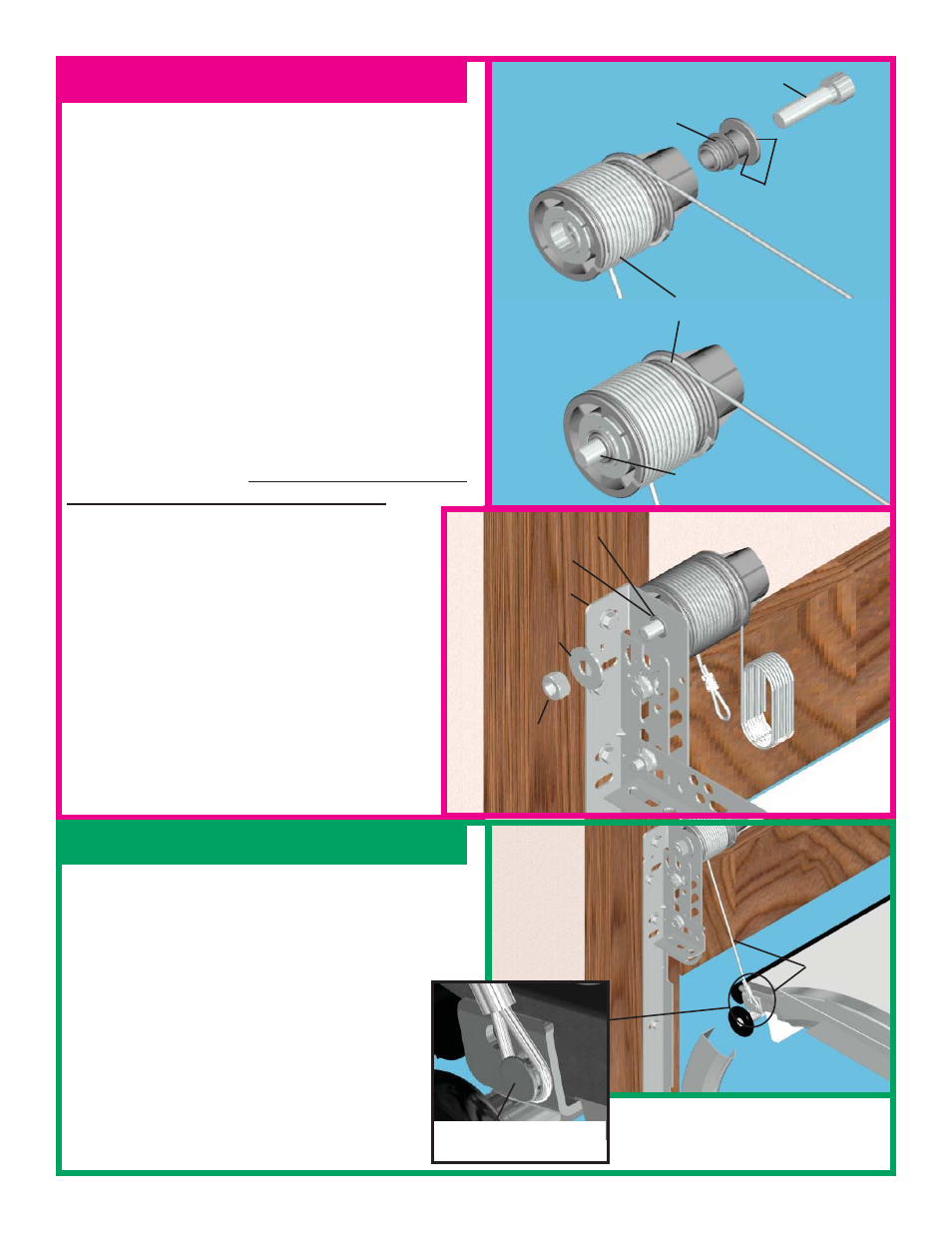

Step 5: Cable Drum Installation

NOTE:

Do not remove shrink wrap from cable

drums until instructed to do so.

Cable drums are right and left. Be sure to check the

identifi cation on each drum to make sure the correct

drum is installed on its corresponding side.

Apply grease to both sides and outer diameter of the

fl ange of the drum shaft.

Insert the 1/2-13 x 2” socket head cap screw into the

drum shaft. Then insert the screw and shaft into the

drum so that the screw threads and drum shaft are

showing out past the drum bearing.

Install the drum/shaft/screw assembly into the 3/4”

hole in the fl ag bracket. Be sure the end of the shaft

is inserted into the hole in the fl ag angle.

Secure assembly with a 1/2” washer and 1/2”

lock nut.

Check to make sure the drum will rotate freely

on the shaft. If not, loosen 1/2” lock nut until the

drum is free to rotate. Repeat for opposite side.

CABLE DRUM

DRUM SHAFT

1/2-13 X 2” SOCKET

HEAD CAP SCREW

1/2-13 X 2” SOCKET

HEAD CAP SCREW

APPLY GREASE

TO DRUM SHAFT

FLANGE

DRUM ASSEMBLY

(SHRINK WRAPPED)

1/2” WASHER

1/2” LOCK

NUT

3/4” HOLE

FLAG

BRACKET

DRUM SHAFT

Locate the end of the lifting cable where the custom loop

was made earlier in the instructions. Carefully pull the

cable, bringing the loop to the milford pin located in the

bottom bracket on the edge of the bottom section. Secure

the cable loop around the milford pin, making

sure the loop is over the head of the milford pin

and around the smaller diameter. Repeat for the

other side.

LIFTING

CABLE

Step 6: Bottom Bracket Lifting Cables

MILFORD PIN ON

BOTTOM BRACKET