H7 series – Toshiba Adjustable Speed Drive H7 Series User Manual

Page 7

H7 Series

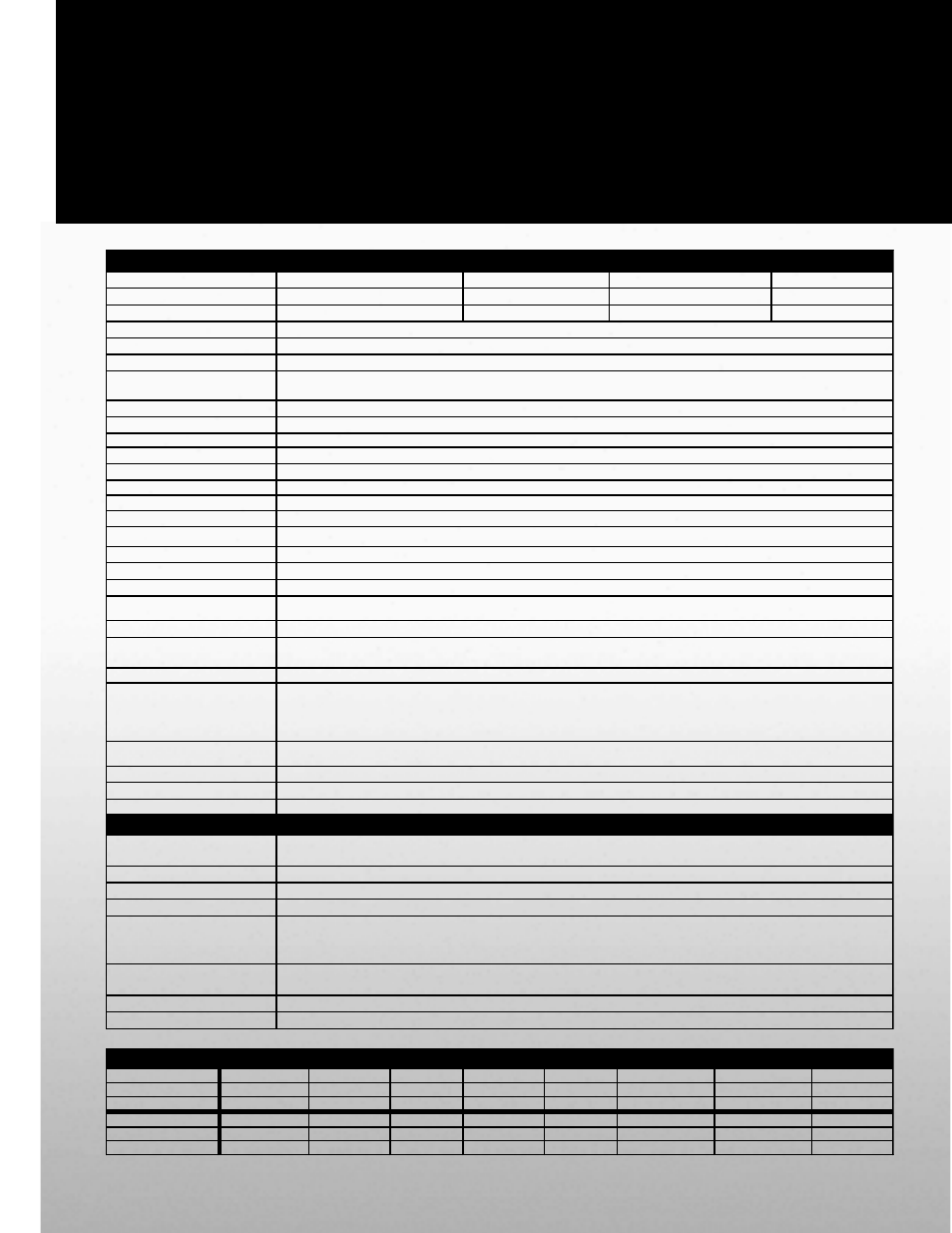

H7 ASD Standard Specifications

Model Range

3 - 150 HP

5 - 400 HP

3 - 15 HP

20 - 350 HP

Voltage Rating

200 - 240 V

380 - 480 V

520 - 600 V

520 - 600 V

Input Voltage Tolerance

�10%

�10%

+5% / -10%

�10%

Voltage Regulation

Main Circuit Voltage feedback control (automatic regulation, 'fixed' and 'control off' selections)

PWM Carrier Frequency

Adjustable between 0.5 – 15 kHz (ASD specific, consult factory)

Control System

Sine Wave PWM System- Flux Field Current Vector Control

V/f Pattern

Open Loop Vector, Closed Loop Vector, Constant Torque, Variable Torque, Auto Torque Boost, Manual Torque Boost, 5-point V/f

custom curve setting

Overload Current Rating

100% continuous or 120% for one minute

Frequency Setting

Rotary Encoder integrated into the EOI, 0 - 10 V, ±10 V, 4 - 20 mA, Binary Input, Motorized Potentiometer Input

Frequency Precision

Analog Input ±0.2% of the maximum output frequency, Digital Input ±0.01% of the maximum output frequency

Frequency Command Resolution

0.01 Hz Operation Panel, 0.1 Hz Analog Input. 10 to 12-bit A-D Converter

Output Frequency Range

0 - 299 Hz

Speed Regulation

Closed Loop (0.01%, 1000:1 speed range), Open Loop (up to 0.1%, 60:1 speed range)

Torque Regulation

Closed Loop (5%, ripple < 2%, �100% range), Open Loop (10%, ripple < 3%, 50% to 100% range)

Discrete Input Terminals

Eight Discrete Input Terminals programmable to 68 functions. The number of terminals may be increased using optional hardware.

Analog Inputs

One 4 - 20 mA, one ±10 V and two 0 - 10 V (one of which is commonly used with a potentiometer)

Discrete Output Contacts

Three Discrete Output Contacts programmable to 60 functions

Analog Outputs

Two 4 - 20 mA / 0 - 1 mA outputs programmable to 33 functions

Signal Isolation

Optional Three-Channel Signal Isolation for 4 - 20 mA input and the AM and FM outputs rated at 750 V

Control Board Communications

Ports

RS232/485 and TTL Ports standard

Power Terminals

Input (L1, L2, L3), Output (T1, T2, T3), DCL (PO, PA), DBR (PA, PB), DC BUS (PA, PC)

Set Point Control (PID)

Proportional Gain, Integral Gain, Feedback Settings Upper / Lower Deviation Limits, Feedback Source Delay Filter, Feedback

Settings Differential Gain

Control Power

DC Bus Control-Power allows control power ride-through during momentary power loss (Except 600 V 100 HP and larger)

Protective Functions

Fault input and outputs are fail-safe configured. Fault codes include: Overcurrent, Overvoltage, Heatsink Overheat, Load-side Short

Circuit, Load Side Ground Fault, ASD Overload, Overcurrent During Start-up, EEPROM Error, RAM Error, ROM Error,

Communications Error, Armature Short, Auto-Tuning Error, Dynamic Braking Overcurrent, Dynamic Braking Resistor Overload,

Emergency Stop, Undervoltage, Overtorque, Open Output Phase, Motor Overload, Loss of Feedback

Retry

ASD can clear fault upon trip automatically.

Programmable to 10 times with wait time up to 10 seconds between retries

Restart

ASD will catch a freewheeling motor smoothly.

Ambient

Temperature: -10 to + 40

�

C, 14 to 104

�

F, Humidity: 95% non-condensing

Installation

NEMA 1

Electronic Operator Interface (EOI)

LCD EOI (Liquid Crystal Display/

Electronic Operator Interface)

240 x 64 graphics capable, back-lit LCD can display multiple parameters simultaneously. Keypad may be operated from an external

power source. Software is flash upgradeable.

LED Indications

Run (Red) / Stop (Green), Local / Remote (Green), DC Bus Charge Indication (Red)

Keys

Local / Remote, Monitor / Program, Run, Enter, ESC, Stop / Reset, Up, Down

Rotary Encoder

Encoder with integrated Enter Key for Frequency and Parameter adjustments

Monitoring

Main Display shows two monitored items or can display up to 45 user-selected scrolling items including: Terminal Input / Output

Status, Forward / Reverse, Frequency Setting Value, Output Frequency, Output Current, Output Voltage, Input Power, Output Power,

Torque Current, Past Faults, Excitation Current, DBR Overload Ratio, ASD Overload Ratio, Motor Overload Ratio,

PID Feedback Value, DC Voltage

Selectable Display Units

Completely configurable along with Scaling Factor Multiplier, Current Display selectable between Amps or �, Voltage Display

selectable between Volts or �

EOI Communications Ports

RS232/485 and TTL Ports standard

Remote-Mount Display

Remote mountable up to 1000' away from the ASD

H7B Dimensions H x W x D (inches)

230 V

3 - 7.5 HP

10 - 25 HP

30 HP

40 - 50 HP

60 HP

75 - 100 HP

125 - 150 HP

460 V

5 - 10 HP

15 - 50 HP

60 - 100 HP

125 HP

150 - 200 HP

250 - 350 HP

400 HP

600 V

3 - 15 HP

20 - 60 HP

75 - 100 HP

125 - 200 HP

200 - 350 HP

HEIGHT

8.47

14.22

15.72

24.63

26.47

38.63

50.00

73.00

WIDTH

7.28

12.16

12.16

17.50

17.50

17.50

24.15

24.00

DEPTH

7.33

11.23

11.23

12.81

12.81

13.78

20.00

20.00

*All dimensions are for "B" units.