Versatile, Built-in communications, Process control – Toshiba Adjustable Speed Drive H7 Series User Manual

Page 3: Adaptability

VERSATILE

Built-In

Communications

In todayʼs fast-paced manufacturing

world, coordinated systems require

communications from drive-to-drive or

drive-to-control systems. Toshibaʼs H7

comes standard with RS232/485 and

TTL communications ports. In addition

to the standard communications

features, Toshiba offers a number

of popular industrial communication

protocol options including: Modbus RTU, Modbus Plus, Ethernet

TCP/IP, Ethernet IP, Profibus DP, DeviceNet and Johnson

Controls Metasys N2.

Process Control

The built-in Proportional/Integral/Derivative (PID) control loop

provides regulation of many processes without the need for

external devices. Deviation limits, online switching and delay

filtering functions are included to enhance the flexibility and the

reliability of PID process control. The torque control and drooping

control functions of the H7 allow precise matching of motor torque

for load sharing applications.

Adaptability

The H7ʼs programmable discrete inputs may be configured to

any of 68 different functions and are independently selectable for

normally open or normally closed operation.

The H7ʼs four multi-function analog inputs have independently

adjustable bias and gain. From common potentiometers for

speed control to analog summing for trim and process control,

the configurability of the H7ʼs analog inputs are adaptable to your

processes.

The removable control terminal strip is available in dry contact,

TTL or 120 VAC configurations and may be optionally DIN Rail

mounted. The operator interface can be easily mounted remotely

and configured for NEMA4/NEMA12 environments.

VERSATILE...

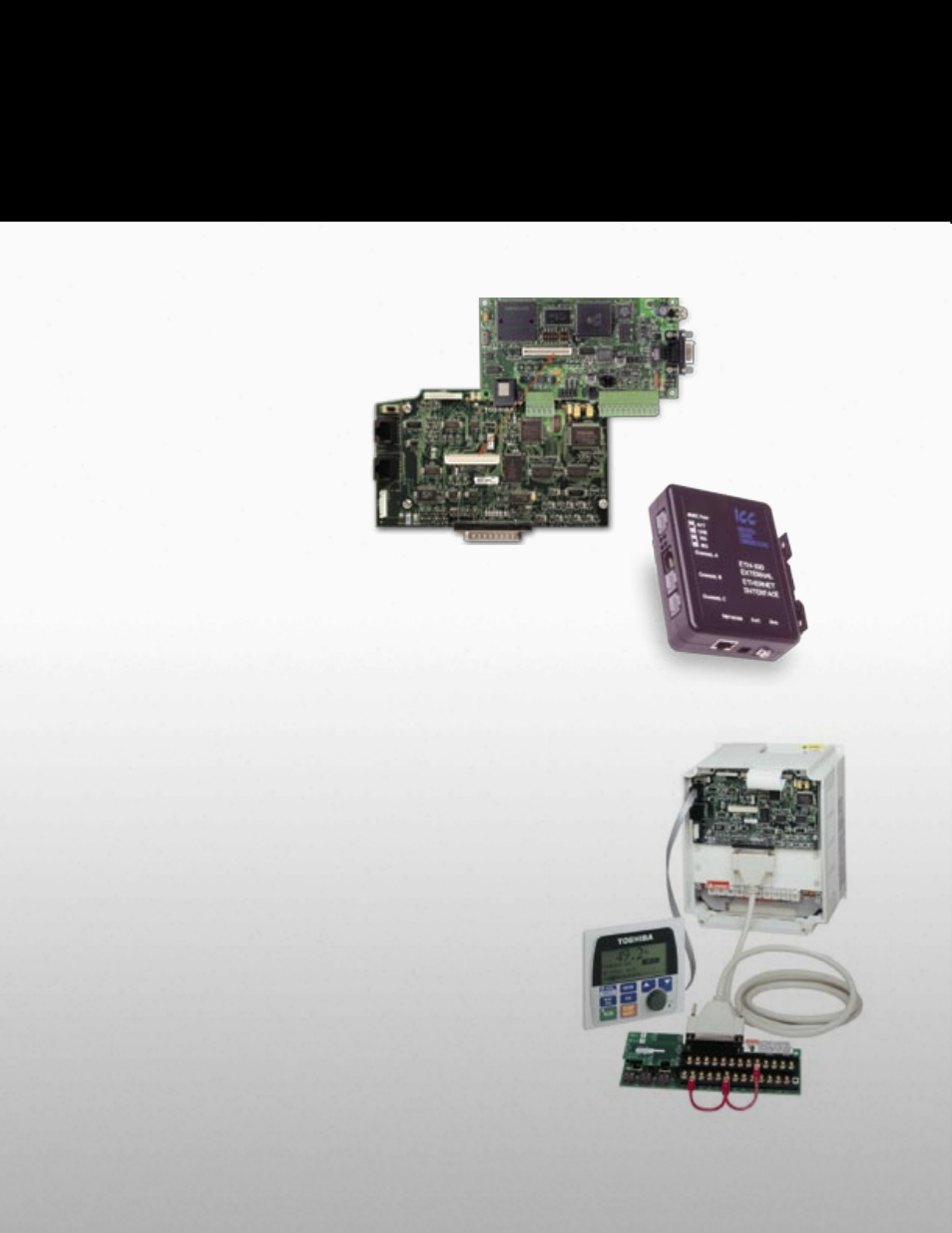

(left) H7 Control

Board with

Internal Stackable

Communication

Card

(below)

Ethernet TCP/IP

Communications

Module

Remote--Mount Interface and Terminal Strip