Opticon LPR5627 User Manual

Page 13

Manual No. 25-ULPNR101-03; Feb, 2003 LPN5627 / LPR5627 Laser Fixed Mount

Scanner

Page 9

3) Quality Bar Code Labels

The quality of the bar code label can affect the scanning performance. Poor quality labels are more

difficult to decode and may result in non-reads or potential misreads. The bar code label should be

printed to specifications. This means that the bars are printed within spec, with the correct widths, no

ink spread, crisps edges and no voids. There should be a sufficient quiet zone on both end of the bar

code label. For best results, the paper or label stock should have a matte finish to diffuse light. The

print contrast signal (which is a comparison of the reflectance of the bars and the background stock)

should be as high as practical.

Measuring Scanner Performance

Two methods are helpful in determining the optimum position of the scanner. The first method is to

program the scanner for Trigger Disable and Continuous Read modes. The scanner will be always on

and will continuously read the same bar code. Since the buzzer sounds each time the bar code is read,

the sound of the buzzer can be used like a “Geiger counter”. As the position of the scanner changes the

sound of the buzzer will change. The buzzer sound will be loudest and most continuous at the best

reading positions.

The Read Rate Test

The second method, the Read Rate Test, provides a mathematical calculation of scanning performance.

In this test the scanner scans a bar code 700 times and then calculates the number of those scans that

resulted in a good decode. That number, expressed as a percentage, will be transmitted to the host.

For example, 93% means that the scanner decoded the bar code symbol 93 times out of the 650 scan

attempts. By performing the Read Rate Test with the scanner mounted in various positions you can

determine which of those locations results in the best performance.

How to perform the Read Rate Test

Perform the following steps after you have correctly configured communications to the computer via your

RS232C port and power is made available to the scanner:

Send the command:

“U8”, not “u8”.

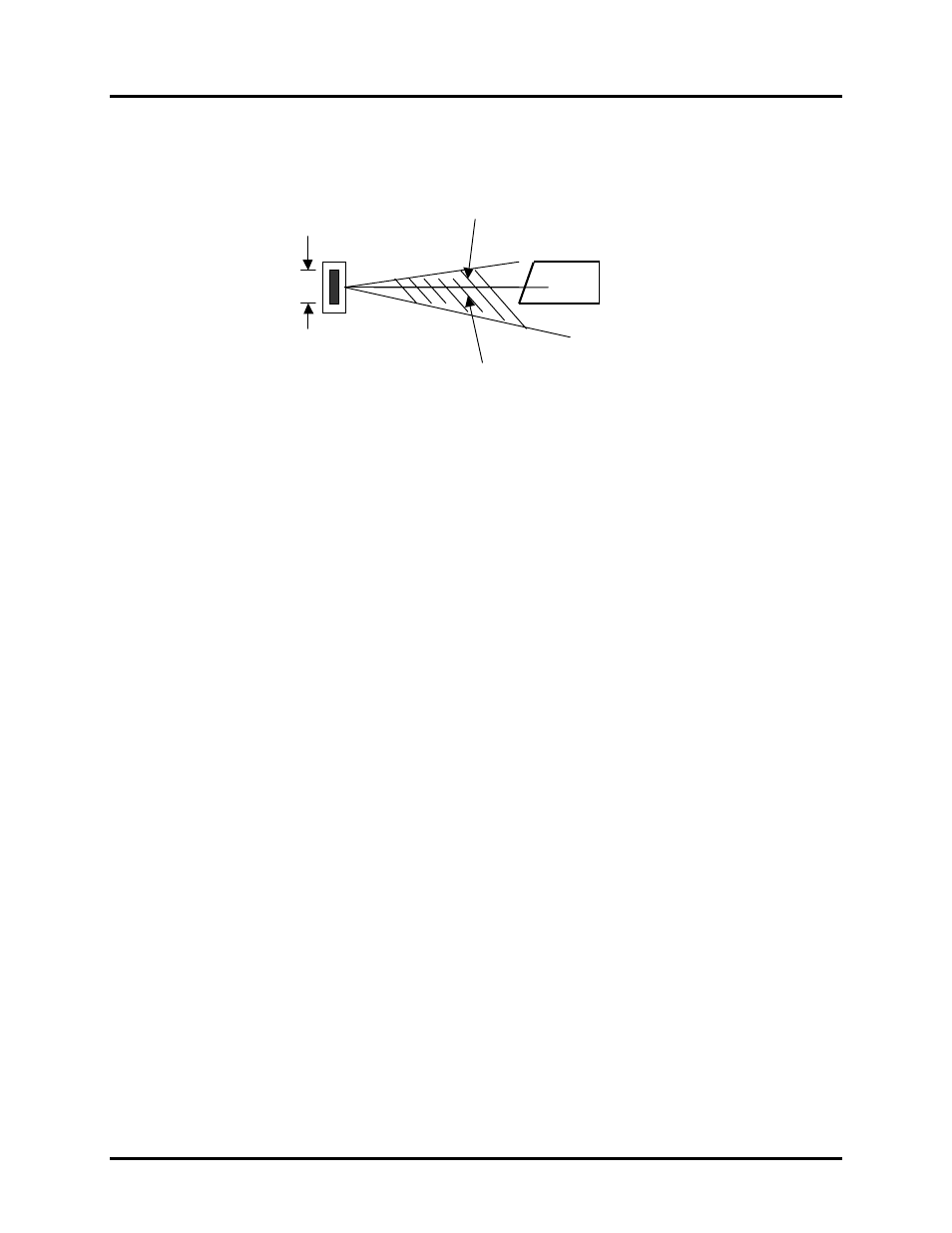

Height

of

barcode

Hatched No-Read

Specular Zone

+5 °

-

10 °