Orion SKYQUEST XT10 CLASSIC User Manual

Page 6

6

used under dark skies and a bright setting is used under light-

polluted skies or daylight.

At the end of your observing session, be sure to turn the power

knob counterclockwise until it clicks off. When the white dots

on the EZ Finder II’s body and power knob are lined up, the EZ

Finder II is turned off.

installing the correctension (Xt) Friction

optimization system

Perhaps the most exciting feature of the SkyQuest Dobsonians

is the CorrecTension Friction Optimization system. Because of

their light weight, 10" and smaller Dobsonians have always

been plagued by insufficient friction on the altitude bearing

surfaces. As a result, such telescopes move up and down

much too freely. This causes problems when the observer tries

to accurately center and track an object for viewing, especially

at higher powers. Also, the telescope becomes very sensitive

to balance, requiring additional equipment such as counter-

weight systems or adjustable side bearings to compensate.

SkyQuest Dobsonians employ a simple yet effective remedy

for the friction problem that obviates the need for such cum-

bersome countermeasures. CorrecTension Friction Optimization

utilizes a spring coil to “pull” the tube assembly down onto the

altitude bearing pads, thereby increasing the friction by just

the right amount. With CorrecTension, you can change eye-

pieces, or add a barlow lens or solar filter without having to

tediously adjust the telescope’s balance as you would with

other Dobsonians. The altitude friction will roughly equal the

azimuth friction, ensuring optimal performance.

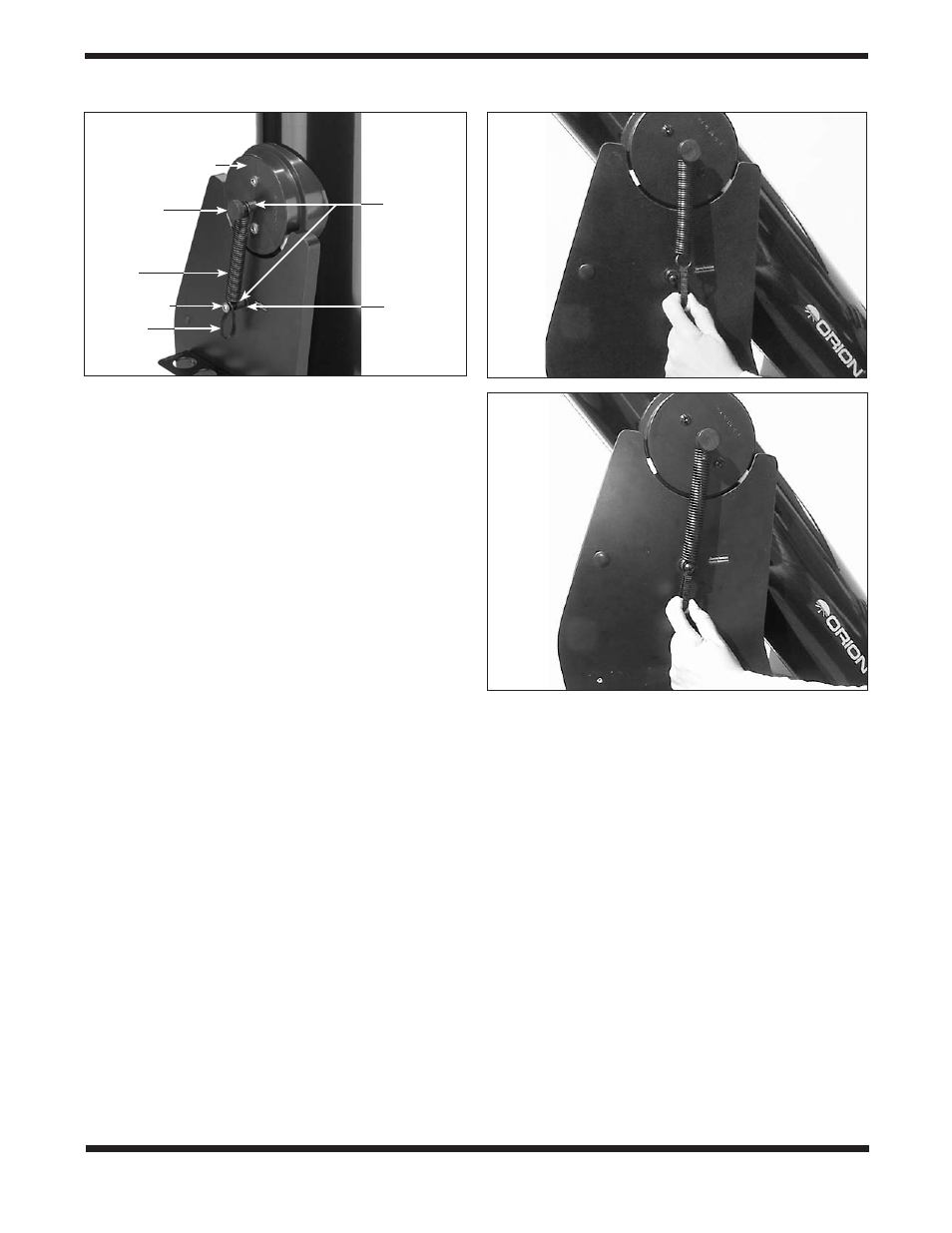

To install the CorrecTension assembly, follow these steps while

referring to Figure 7:

1. Put one of the black nylon spacers on a black Phillips-head

screw. The spacer should be oriented so the narrow end

seats against the head of the screw. Slip one of the black

1/4" washers over the end of the screw. Now, thread the

screw into the hole in the base side panel just below the

cradle. The screw will thread into the preinstalled insert in

the hole. Use a Phillips screwdriver to tighten the screw.

Repeat this procedure on the opposite side panel.

2. Next, insert one of the screws with a round plastic knob

attached through the end ring of one of the springs. Slip

a black nylon spacer onto the screw. Orient the spacer so

the narrow end is closest to the knob. Thread the entire

assembly into the hole in the center of the telescope’s

altitude side bearing until tight. The end ring of the spring

should seat onto the narrow end of the spacer. Repeat this

procedure for the other altitude side bearing.

3 Attach a pull loop to the free end of each spring. Slide the loop

through the opening in the ring on the end of the spring.

4. Now, pull each spring down using the pull loop, and posi-

tion the spring’s end ring over the head of the Phillips

screw (installed in Step 1) and onto the narrow part of the

nylon spacer, as shown in Figure 8b. You needn’t attach

both springs simultaneously; one at a time is fine.

Figure 8.

(a) To attach the spring to the base, grip the pull loop

with your index finger and pull down on the spring.

(b) While pulling

down, slip the end ring of the spring over the bolt head and onto the

narrow part of the nylon spacer, then release the pull loop.

a.

b.

Figure 7.

Close-up view of the CorrecTension system, which pulls

the tube assembly down onto the altitude bearing pads.

Black nylon

spacers

1/4" washer

(black)

Altitude side bearing

Screw with

round knob

Spring

Phillips-head

screw (black)

Pull loop