Table 9-4. average tubing life (cont'd), 5 vinyl 60, 0 vinyl 60 – Omega Vehicle Security OMEGAFLEX FPU500 User Manual

Page 45: 0 vinyl 40, 0 vinyl 30, 5 norprene 500, 0 norprene 500, 0 norprene 400, Mineral oil, 0 400 cps mineral oil

Specifications

9

9-5

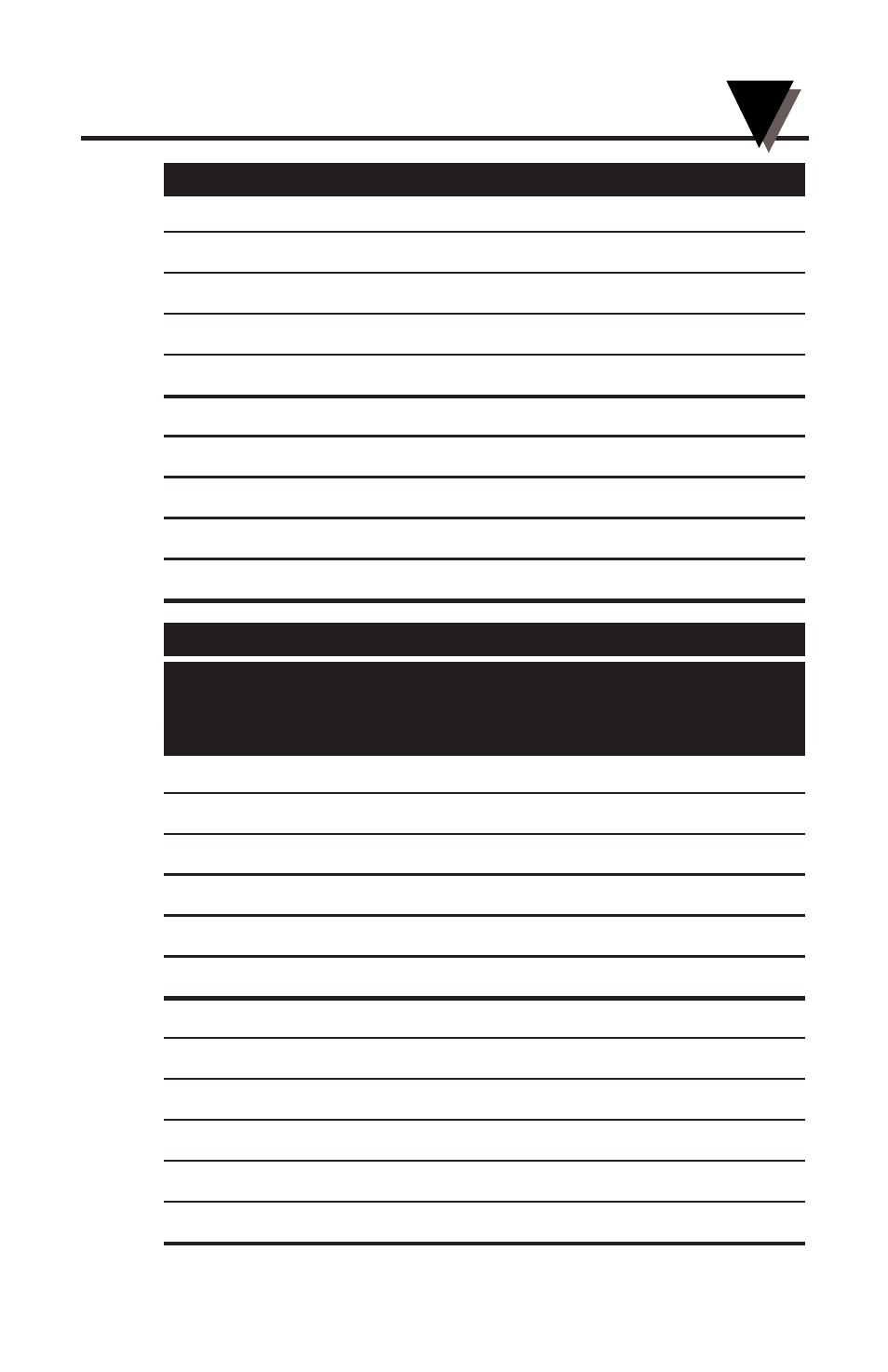

Table 9-4. Average Tubing Life (Cont'd)

1

⁄

16

1.5

1

⁄

16

1.5

Vinyl

60

1

⁄

16

1.5

1

⁄

8

3.0

Vinyl

60

1

⁄

16

1.5

3

⁄

16

4.5

Vinyl

60

1

⁄

16

1.5

1

⁄

4

6.0

Vinyl

40

1

⁄

16

1.5

5

⁄

16

8.0

Vinyl

30

1

⁄

16

1.5

1

⁄

16

1.5

Norprene

500

1

⁄

16

1.5

1

⁄

8

3.0

Norprene

500

1

⁄

16

1.5

3

⁄

16

4.5

Norprene

500

1

⁄

16

1.5

1

⁄

4

6.0

Norprene

400

1

⁄

16

1.5

5

⁄

16

8.0

Norprene

400

Table 9-6. Average Flow Rates for Viscous Liquids

Tubing Size

Liquid

Tubing Wall

Inner

mL per

Viscosity

Thickness

Diameter

Revolution

Mineral Oil

1

⁄

16

"

1

⁄

32

"

0

400 cps

Mineral Oil

1

⁄

16

"

1

⁄

16

"

0.005

400 cps

Mineral Oil

1

⁄

16

"

1

⁄

8

"

0.04

400 cps

Mineral Oil

1

⁄

16

"

3

⁄

16

"

0.15

400 cps

Mineral Oil

1

⁄

16

"

1

⁄

4

"

0.20

400 cps

Mineral Oil

1

⁄

16

"

5

⁄

16

"

0.25

400 cps

Molasses

1

⁄

16

"

1

⁄

32

"

0

8,000 cps

Molasses

1

⁄

16

"

1

⁄

16

"

0.002

8,000 cps

Molasses

1

⁄

16

"

1

⁄

8

"

0.01

8,000 cps

Molasses

1

⁄

16

"

3

⁄

16

"

0.07

8,000 cps

Molasses

1

⁄

16

"

1

⁄

4

"

0.08

8,000 cps

Molasses

1

⁄

16

"

5

⁄

16

"

0.10

8,000 cps

Flow rate tests were done with 20°C liquids at 0 psi back pressure