Raypak 0180B User Manual

Page 5

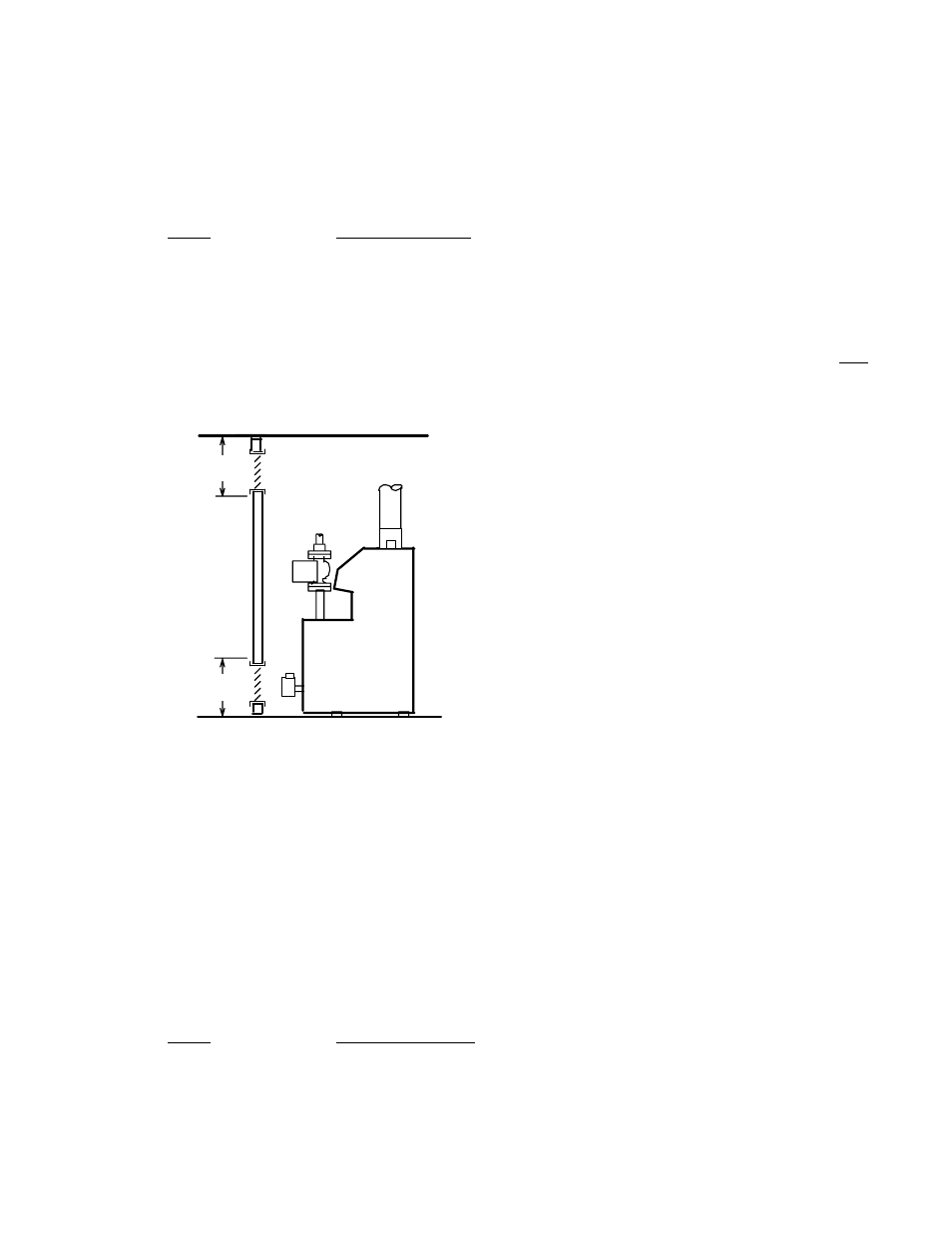

2) When the boiler is installed in a confined space

such as a utility room or closet (Models 0030,0042

and 0066 only), where all air is supplied from inside

the building, the boiler room must be provided with

two openings, each one having a minimum net free

area, in square inches as follows:

Model

Sq. In. of Free Area

0030, 0042 & 0066

100

One opening shall be within 12 inches of the top,

and the other opening within 12 inches of the floor. If

additional gas appliances are installed in the same

space, the total input of all gas appliances installed in

the same space, must be considered in the calculation.

Refer to Sec. 5.3.5 of the latest edition of the National

Fuel Gas Code for additional requirements.

Fig. #8198.0

NOTE: If louvers, grills or screens are used on the

openings, obtain the net free area from their supplier or

manufacturer. If the design free area of a louver is not

known nor available, it shall be assumed that wood

louvers will have 20-25 percent free area and metal

louvers will have 60-75 percent free area as shown in

Sec. 5.3.5 National Fuel Gas Code.

3) If the boiler room is located against an outside wall

and air openings can communicate directly with the

outdoors, the two openings on the outside wall must

each have a net free area, in square inches as

follows:

Model

Sq. In. Of Free Area

0030 & 0042

12

0066

18

0090

24

0135

35

0180

45

Location of the openings is the same as in the

previous case - that is, within 12 inches of the top, and

within 12 inches of the bottom of the enclosure. If

horizontal ducts are used, the area must be doubled and

the duct area shall not be less than the area of the

openings they connect, and in no case shall the small-

est dimension be less than 3 inches.

VENTING CONNECTIONS

These boilers have built-in drafthoods. Vent piping

the same size or larger than the draft hood outlet is

recommended; however, when the total vent height

(drafthood outlet to vent terminal) is at least ten (10)

feet, the vent pipe size may be reduced by one size only

as specified in Part 11, Note 2 and in Appendix G of the

latest edition of the National Fuel Gas Code, ANSI Z

223.1. As much as possible avoid horizontal runs of

vent pipe and too many elbows. If installation requires

horizontal runs, the vent pipe must have a minimum of

1/4 inch per foot rise and should be supported at not less

than five foot intervals. Maximum vent connector hori-

zontal length shall be 1-1/2 feet (18 inches) for each inch

of connector diameter as follows.

Boiler Size

Vent Connector

Max Horizontal

Diameter

Length - FT

30 & 42

4"

6

66 & 90

5"

7.5

135

6"

9

180

7"

10.5

Gas Vents supported only by the flashing and

extending above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads. We recommend use of insulated vent pipe

spacer through the roofs and walls.

For protections against rain or blockage by snow,

the vent pipe must terminate with a listed vent cap which

complies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z 223.1.

The discharge opening must be a minimum of two

feet vertically from the roof surface and at least two (2)

feet higher than any part of the building within ten (10)

feet. Vent stack shall be at least five (5) feet in vertical

height above the drafthood outlet. The vent cap location

shall have a minimum clearance of four (4) feet horizon-

tally from, and in no case above or below, unless a 4-foot

horizontal distance is maintained, from electric meters,

gas meters regulators and relief equipment.

12"

12"

5