Receiving equipment, General specifications – Raypak 0180B User Manual

Page 3

1. RECEIVING EQUIPMENT

On receipt of your equipment it is suggested that

you visually check for external damage to the carton. If

the carton is damaged, it is suggested that a note be

made on the Bill of Lading when signing for equipment.

Remove the boiler from the carton and if it is damaged

report the damage to the carrier immediately. Be

sure that you receive the number of packages indicated

on the Bill of Lading. Claims for shortages and

damages must be filed with carrier by consignee.

Purchased parts are subject to replacement only

under the manufacturer's warranty. Debits for defective

replacement parts will not be accepted and defective

parts will be replaced in kind only per our standard

warranties.

When ordering parts, you must specify Model and

Serial Number of boiler. When ordering under warranty

conditions, you must also specify date of installation.

Raypak recommends that this manual be re-

viewed thoroughly before installing your Raypak

Boiler. If there are any questions which this manual

does not answer, please contact your local Raypak

representative.

2. GENERAL SPECIFICATIONS

The Raypak hydronic boilers are design certified by

the American Gas Association, and tested under the

requirements of the American National Standard, ANSI

Z21.13. Each boiler has been constructed and pressure

tested in accordance with the requirements of Section

IV of the American Society of Mechanical Engineers

Code, and factory fire tested.

The boilers are designed for indoor installation with

a built-in drafthood, and a built-in sub-base for combus-

tible flooring. Models are available with standing pilot,

or with intermittent ignition device (I.I.D.). The boilers

are equipped with the following components: water

circulation pump, pressure relief valve, temperature/

pressure gauge, adjustable high limit switch, drain

valve, fast response temperature sensor, 40 VA trans-

former, pump relay, vent thermal switch, flame roll-out

switch, and redundant combination gas valve for use

with either natural or propane gases. Two-staged gas

valve (50% firing on 1st stage) is standard on models

H-0090, H-0135 and H-0180.

The automatic ignition models and some standing

pilot models are provided with a plug-in connector that

is compatible with the Honeywell D80D vent damper.

Similar type vent dampers made by other manufactur-

ers, and design certified by a nationally-recognized

testing Agency, under the ANSI Z21.66 standards, may

also be used.

Follow the installation instructions furnished with the

vent damper package. The plug-in connector can also

be used with power venters. Refer to the specific

installation instructions supplied by the power vent

manufacturer.

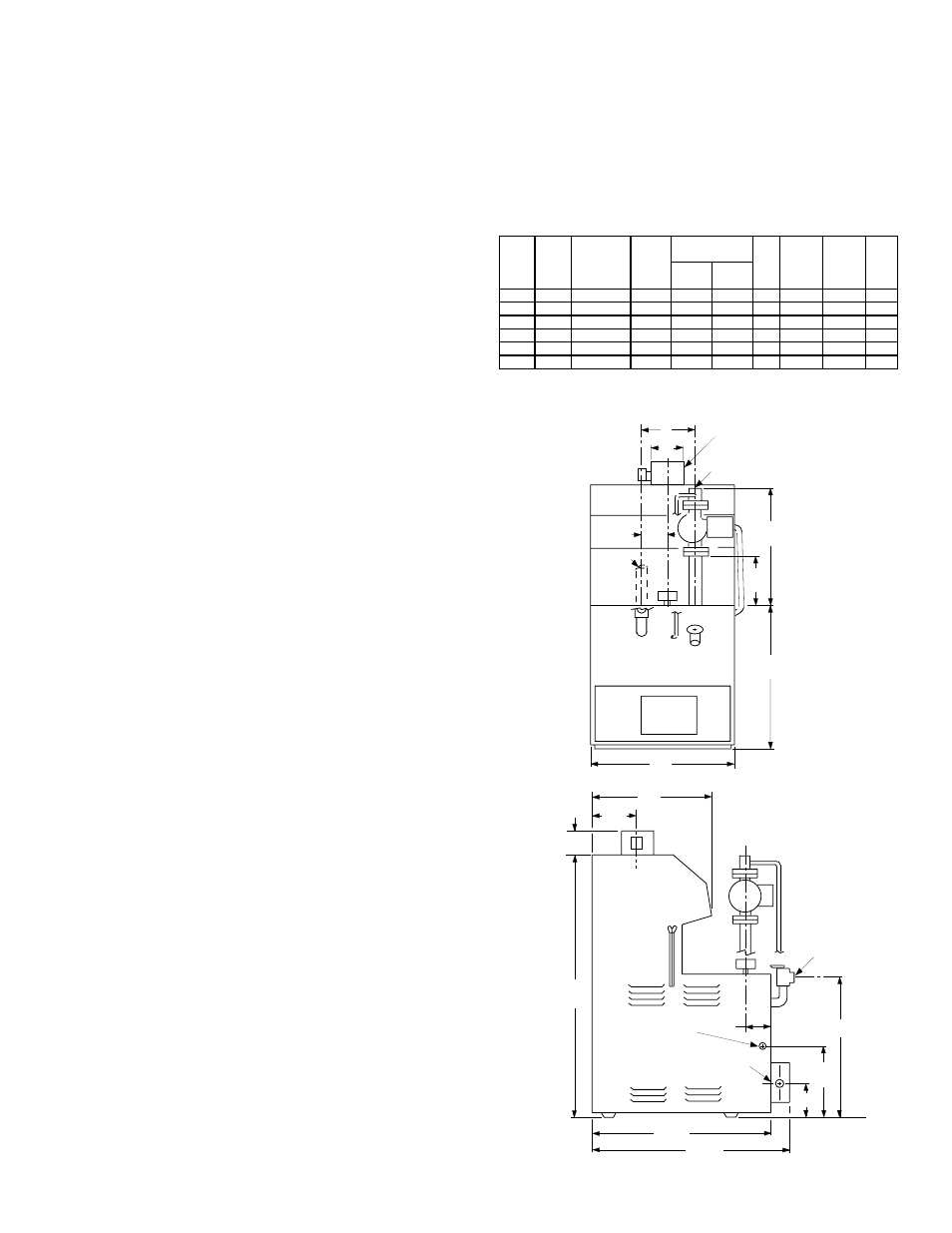

SPECIFICATIONS AND DIMENSIONS

3

K

16

4

1

/

2

33

1

/

4

22

1

/

8

12

1

/

2

5

18

3

1

/

4

26

1

/

2

C

THERMOSTAT CONN

(ELECTRICAL CONN

ON OTHER SIDE)

GAS

CONN

3/4 NPT PIPE

TO DRAIN

A

11

7

/

8

6

INLET

OUTLET

3

1

/

8

MIN

19

AUTOMATIC

VENT DAMPER

(FIELD INSTALLED)

B

HEATING

NET

K

INPUT CAPACITY

I=B=R WATER

GAS

VENT

MODEL MBH

MBH

RATING NPT.

NPT.

A

B

C

DIA.

H-0030

30

25

22

1"

1/2"

11"

5 3/4

5 1/2

4"

H-0042

42

35

30

1"

1/2"

11"

5 3/4

5 1/2

4"

H-0066

66

54

47

1"

1/2"

11"

5 3/4

5 3/4

5"

H-0090

90

74

64

1"

1/2"

11"

5 3/4

5 3/4

5"

H-0135

135

109

95

1 1/4"

1/2"

18"

6 1/4

6 1/4

6"

H-0180

180

148

129

1 1/4"

1/2"

18"

6 1/4

8.0

7"

CONNECTIONS

PIPING

Fig. #8978.1