Reloading, Paper supplies, What – Ricoh MP1350 User Manual

Page 6: Liked, What we would like to see, Paper handling: paper input

Copyright © 2006 MCA Internet, LLC dba BERTL.

13 November 2006

All Rights Reserved. The license under which this document is made available and applicable law prohibit any reproduction or further transmission of any portion of this document. This

document may only be viewed electronically through the www.BERTL.com Web site and may not be stored in electronic or hard copy format. Any reproduction of trademarks is strictly

prohibited. BERTL accepts no responsibility for any inaccuracies or omissions contained in this document.

Page 6

Ricoh Aficio MP1350

Reloading Paper Supplies

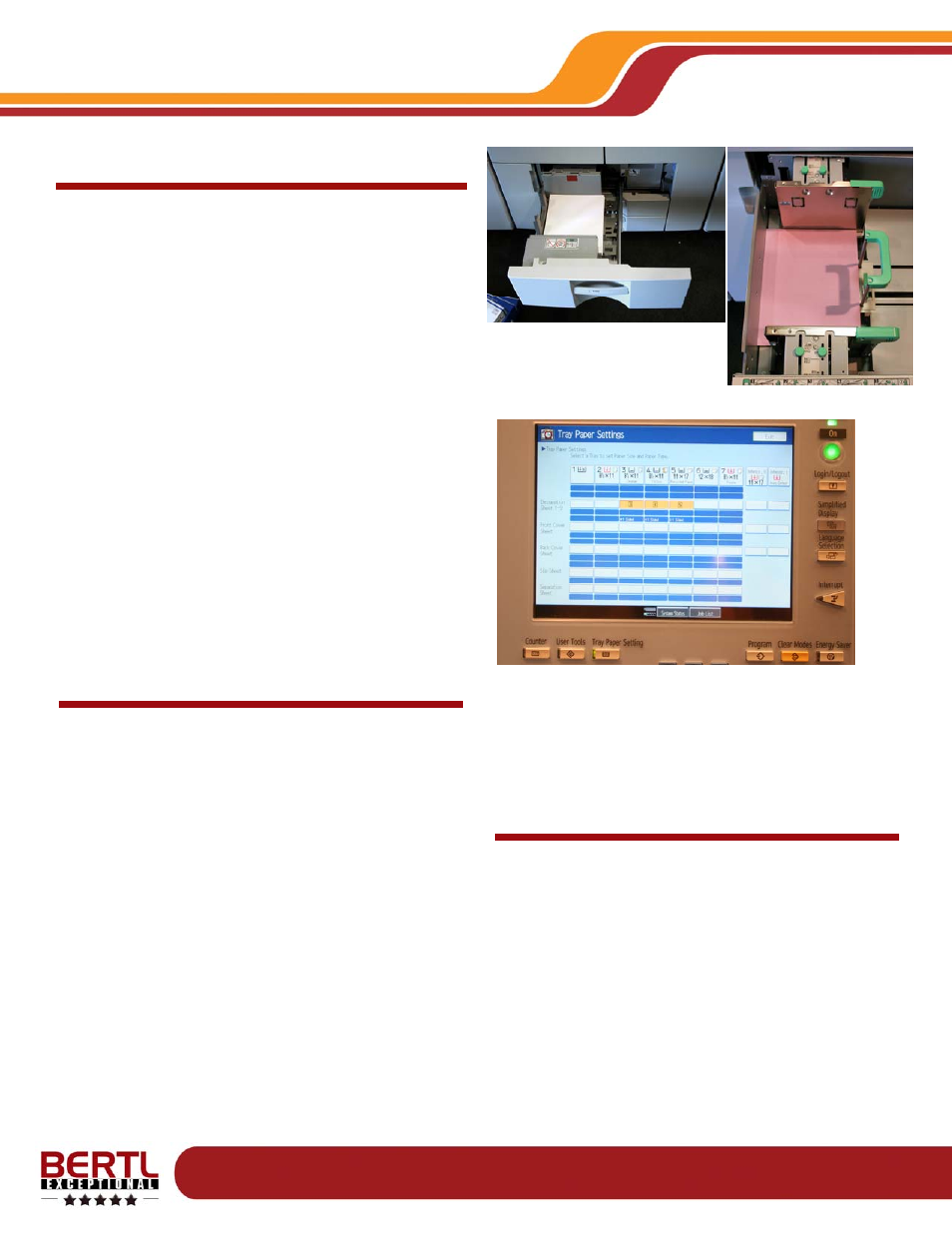

The main tandem unit on the device is easy to reload with

users dropping in up to two reams of media into each side

of the unit with ease.

BERTL analysts were impressed by the build and design of

the universal drawers in the LCT modules. They were sol-

idly constructed and easy to use and refill. To adjust in one

direction (the long edge) users release a locking lever

found to the right of the metal paper guide. Once released,

users can slide the guide plate stopping at any position

where the plate can then be locked again. The other direc-

tion guide can also be adjusted easily with a sliding guide

and green color coded handles. To avoid guide movement

during long print runs, the sliding guides can be locked in

place using green color coded twist screws. BERTL prefers

the rail design that Ricoh has adopted rather than the pre-

cut guides that some competing units use. This slide is

faster, allows for a wider range of custom stocks, and met

with BERTL analysts’ standards.

BERTL was also pleased to see that opening the paper

decks is now facilitated via a handle that can be gripped

from above or below. This makes the process easier than

the bottom gripping design of previous generation products.

WHAT WE LIKED:

• The Ability to reload one side of the tandem drawer

while the other side is loaded and feeding paper into the

run allows other media sources to be used for other

stocks.

• Ejection of unwanted tab sheets allows companies to

bulk purchase one tab set stock rather than order tab

sets that depend upon the job, thus allowing a wider

range of front office documents to be printed on de-

mand with less opportunity for user errors.

• The support for legal and ledger media supplies allows

longer uninterrupted print runs of non letter documents

to be carried out. This can be an important considera-

tion for some vertical and horizontal sector markets

such as legal, government, architectural, marketing de-

partments, and manufacturing.

• The twin unit cover inserter capability extends docu-

ment production capabilities of the device beyond that

offered by some high end departmental MFP products.

• Handles on drawers can now be gripped from above

and below, making reloading easier.

• The well designed paper guide adjustment system al-

lows users to quickly and accurately change media

types and guides in a multi-user, mixed workflow envi-

ronment.

• The tray settings feature displays an overview of all pa-

per drawer, pre-defined settings.

WHAT WE WOULD LIKE TO SEE:

• Support for coated stocks would allow the device to be

used for overprinting, pre-printed offset shell template

sheets.

Paper Handling: Paper Input

Above: Tandem 2 x 1,000 sheet paper

feed unit with one side loaded and one

side being reloaded

Right: Large capacity tray loaded with

letter-sized colored card stock