Installation, Gas pipe pressure testing, Inst alla tion – Regency L234-NG User Manual

Page 13

Regency

®

L234 Direct Vent Gas Insert

13

INST

ALLA

TION

GAS PIPE

PRESSURE TESTING

The appliance must be isolated from the gas supply piping system by closing

its individual manual shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than 1/2 psig.

(3.45 kPa). Disconnect piping from valve at pressures over 1/2 psig.

The manifold pressure is controlled by a regulator built into the gas control,

and should be checked at the pressure test point.

NOTE: To properly check gas pressure, both inlet and manifold

pressures should be checked using the valve pressure ports

on the valve.

1) Make sure the valve is in the "OFF" position.

2) Loosen the "IN" and/or "OUT" pressure tap(s), turning counterclockwise

with a 1/8" wide fl at screwdriver.

3) Attach manometer to "IN" and/or "OUT" pressure tap(s) using a 5/16"

ID hose.

4) Light the pilot and turn the valve to "ON" position.

5) The pressure check should be carried out with the unit burning and

the setting should be within the limits specifi ed on the safety label.

6) When fi nished reading manometer, turn off the gas valve, disconnect

the hose and tighten the screw (clockwise) with a 1/8" fl at screwdriver.

Note: Screw should be snug, but do not over tighten.

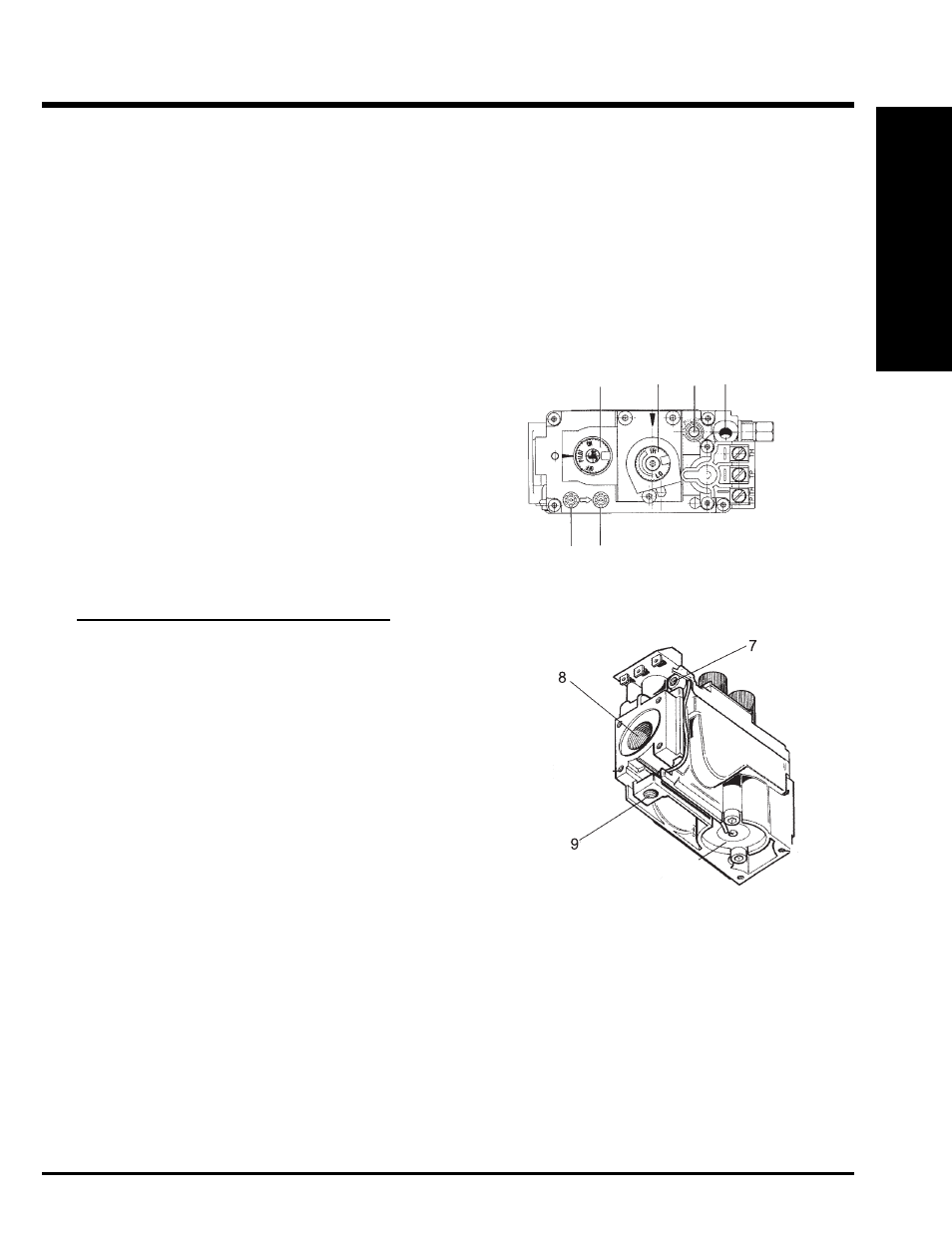

SIT VALVE DESCRIPTION

1) Gas

on/off

knob

2) Manual

high/low

adjustment

3) Pilot

Adjustment

4) Thermocouple

Connection

-

option

5) Manifold (Outlet) Pressure Tap

6) Inlet

Pressure

Tap

7) Pilot

Outlet

8) Main Gas Outlet

9) Alternative

TC

Connection

Point

1

2

3

4

5

6

IN

OUT

INSTALLATION