Raypak B-195 User Manual

Page 12

SEQUENCE OF OPERATION

The booster heater is designed to maintain a tempera-

ture of 180 deg. F (82.2 Deg. C) of 490 GPH water

required for the rinse cycle of a commercial dish-

washer. An inlet temperature of 140 Deg. F (60 Deg.

C) will produce optimum results.

Provided the necessary power, water, gas and

vent connections are completed, the unit is started by

the activation of the on/off switch located on the left side

panel. The blower motor and the circulator pump will

also start.

Providing the operating and safety controls includ-

ing the vent switch is closed, the ignition module will

energize the ignitor. The hot surface ignitor then heats

up, and is proven to be capable of ignition. The gas

valve is then energized. The burner will be lit and the

remote sensor will sense the flame. If the burner flame

is not sensed within four seconds the gas valve will shut

off. The ignition module will try for a total of three cycles

to prove ignition. If, after third cycle ignition is not

proven, the module will go into lockout, and a Red-LED

will start blinking. To recycle the burner, momentarily

turn the power switch to the off position and then to the

on position. When the water temperature exceeds the

setting of the operating controller, the burner will shut

off until the next call for heat. The operating limit control

is factory set at 185°F. Combustion air blower and the

circulator pump will cycle On/Off with the operating limit

controller.

START UP PROCEDURES

SECTION 1. FILLING THE SYSTEM

Fill the heater system with water purging all air. It

is recommended that the system be flushed before

putting heater into operation . This can be done by

opening the drain valve located under the stainless

steel tank.

SECTION 2. CHECKING CIRCULATOR/PUMP

Before lighting the heater, make sure the circulator

is operating properly. With the gas valve in the off

position, activate the power switch. The circulator

should start immediately. Allow the circulator to pump

the water through the system.

NOTE: The circulator motor does not require lubrica-

tion.

12

4. START UP AND OPERATION

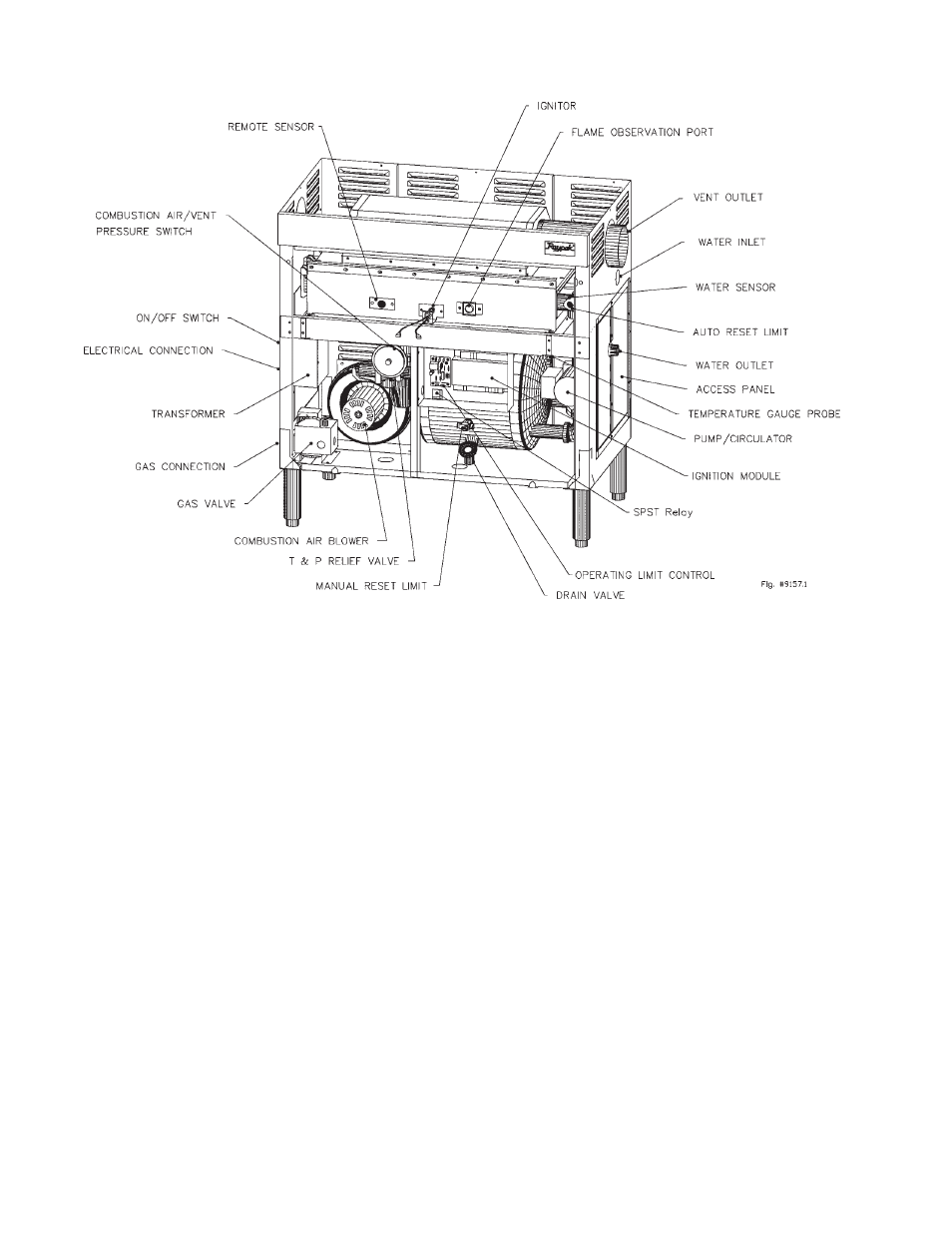

COMPONENT LOCATION