Maintenance – RIDGID OL50145MW User Manual

Page 15

5

ON OFF O

I

ON

MAINTENANCE

WARNING:

When servicing use only identical RIDGID

®

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear safety goggles or safety glasses with

side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a

dust mask.

WARNING:

Always release all pressure, disconnect from

power supply, and allow unit to cool to the touch

before cleaning or making repairs on the air

compressor.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

As a routine part of air compressor maintenance, it is also

advised that the oil is routinely checked for proper levels.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals

can damage, weaken or destroy plastic which

may result in serious personal injury. Electric tools

used on fiberglass material, wallboard, spackling

compounds, or plaster are subject to accelerated

wear and possible premature failure because

the fiberglass chips and grindings are highly

abrasive to bearings, brushes, commutators,

etc. Consequently, we do not recommend using

this product for extended work on these types

of materials. However, if you do work with any of

these materials, it is extremely important to clean

the product using compressed air.

LUbRICATION

All of the bearings in this product are lubricated with a

sufficient amount of high grade lubricant for the life of the

unit under normal operating conditions. Therefore, no further

lubr

ication is required.

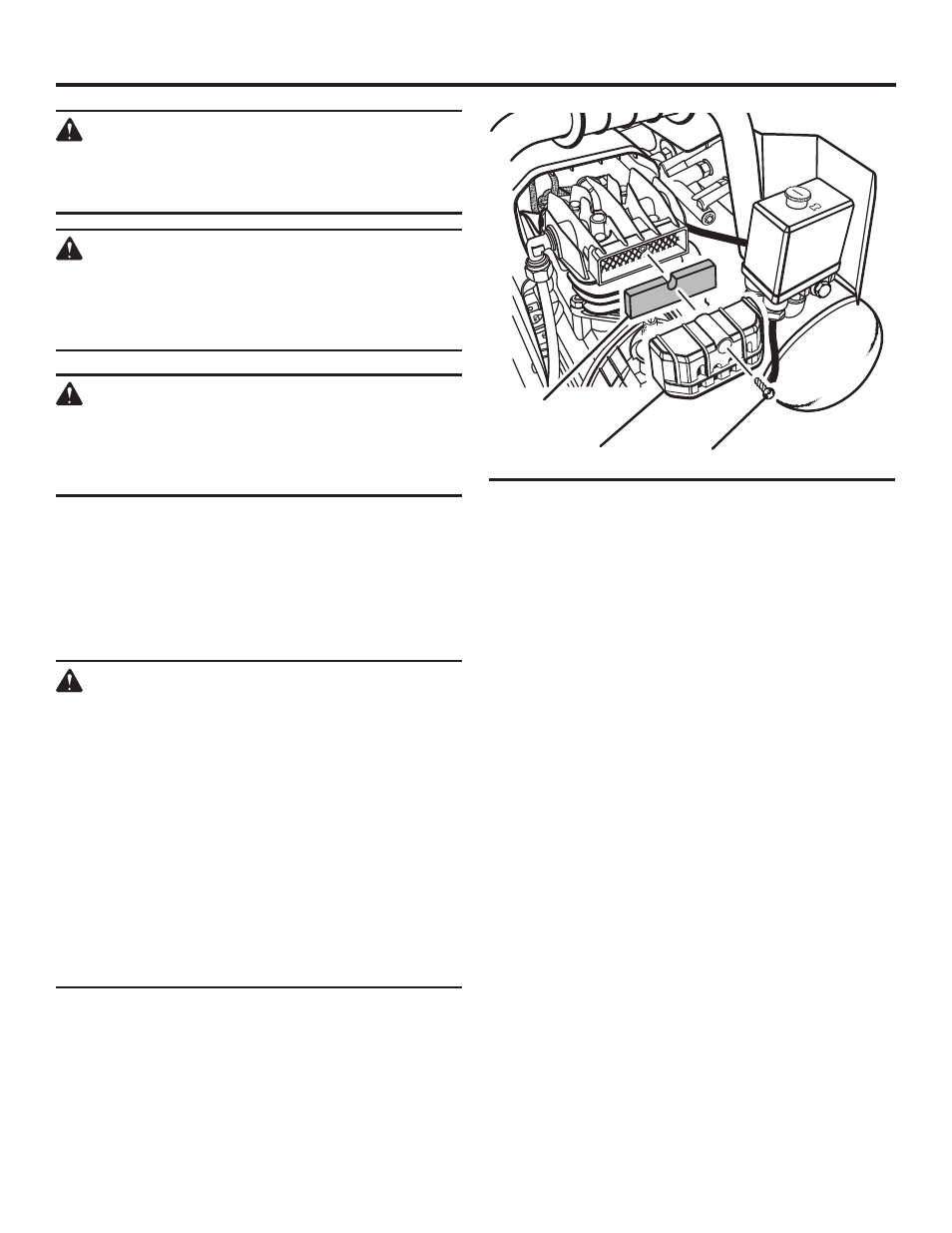

REPLACING THE AIR FILTER

See Figure 14.

Remove the air filter screw.

Remove the air filter cover.

Remove the air filter.

Install new air filter.

Install the air filter cover.

Install the air filter screw.

REPLACIN

G THE SEMI-PNEUMATIC TIRE

Remove the screws installed through the holes and metal

brackets in the tire rod.

Remove the tire rod and pneumatic tire assembly.

Remove hitch pins and washers on either side of semi-

pneumatic tire.

Remove semi-pneumatic tire.

To install new semi-pneumatic tire, see

Installing the

Semi-Pneumatic Tire in Assembly.

Fig. 4

air filter

air filter coVer

screw