Electrical power connections – Raypak 503-2003 User Manual

Page 20

20

The MVB 503-1503 heaters are wired for 120 VAC, 12

amps while the MVB 1753 & 2003 heaters are wired

for 120 VAC, 18 amps. Consult the wiring diagram

shipped with the heater. Before starting the heater,

check to ensure proper voltage to the heater and

pump.

Boiler mounted pumps (up to

3

⁄

4

hp) get their power

supply directly from the boiler power supply (connec-

tions in rear wiring box). Install a circuit breaker sized

sufficiently for both the heater and the pump. Pumps

larger than

3

⁄

4

hp must use a separate power supply

and run the power through the optional pump contac-

tor which is located in the rear wiring box. Use

appropriately-sized wire as defined by NEC, CSA

and/or local codes. All primary wiring should be 125%

of minimum rating.

If any of the original wire as supplied with the heater

must be replaced, it must be replaced with 105°C wire

or its equivalent.

All field wiring connections to the MVB heater are

made inside the rear wiring box as shown in Fig. 16.

Pump power should be taken from terminals 2 (Com),

3 (GND) and 6 (Hot) –

3

⁄

4

hp and smaller ONLY. Power

to the MVB heater should be connected to terminals 1,

2, and 3 as noted in Fig. 16. Sensors, interlocks,

enable/disable, and various options are wired into ter-

minals 1–12 as noted in Fig. 16.

The gas valve pressure regulator on the heater is

nominally preset as noted in Table I.

During normal operation, carbon dioxide should be 8.5

to 9.0% at full fire for natural gas and between 9.5 and

10.0% for propane gas. Carbon monoxide should be

‹100ppm.

Electrical Power Connections

Installations must follow these codes:

•

National Electrical Code and any other national,

state, provincial or local codes or regulations hav-

ing jurisdiction.

•

Safety wiring must be NEC Class 1.

•

Heater must be electrically grounded as required

by the NEC.

•

In Canada, CSA C22. 1 C.E.C. Part 1.

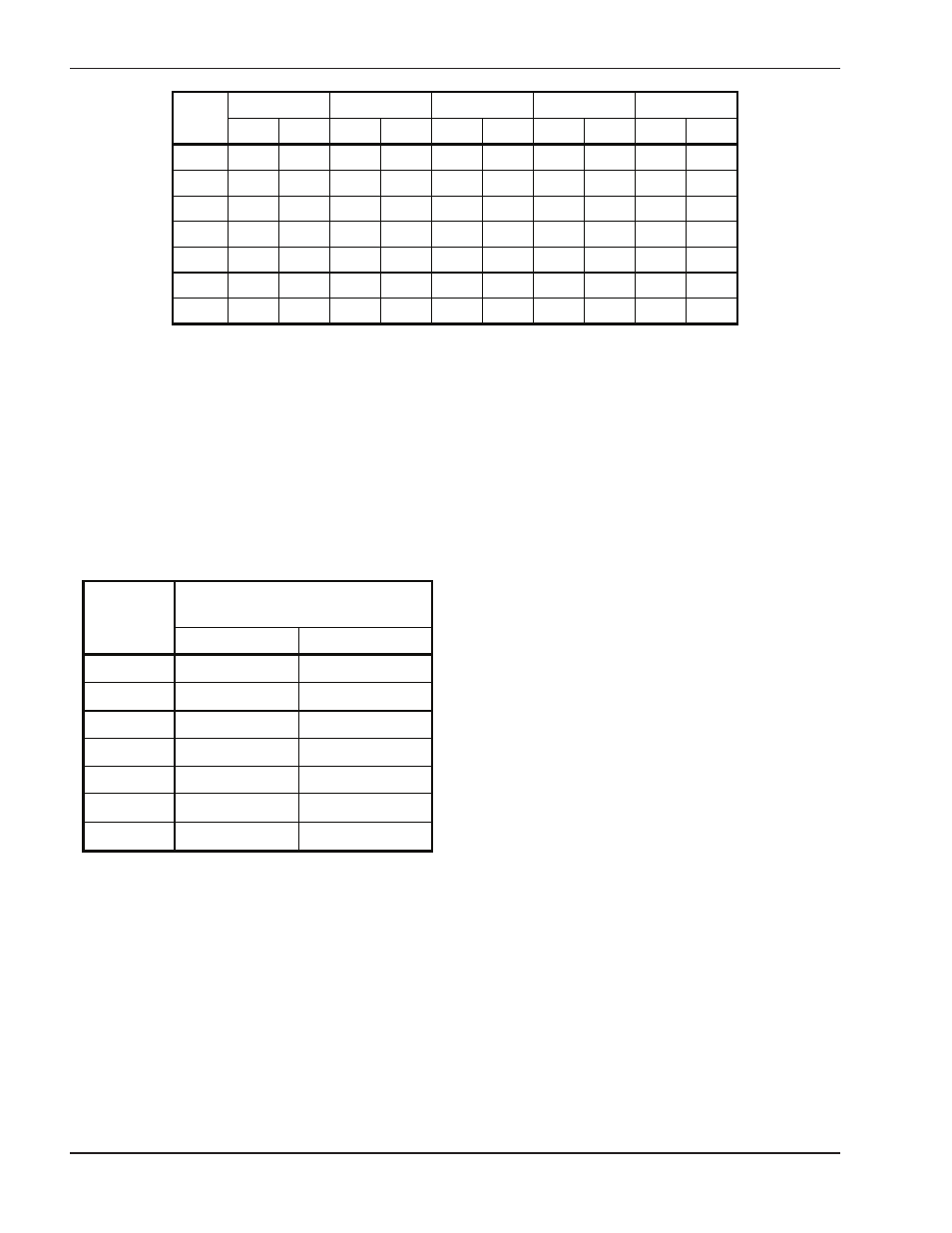

1” NPT

1-1/4” NPT

1-1/2” NPT

2” NPT

2-1/2” NPT

Model

No.

N

P

N

P

N

P

N

P

N

P

503

15

35

65

150

130

360

N/A

N/A

N/A

N/A

753

5

15

65

100

75

180

250

N/A

N/A

N/A

1003

N/A

N/A

35

55

35

90

125

300

300

N/A

1253

N/A

N/A

15

25

25

60

85

225

200

300

1503

N/A

N/A

10

15

15

25

60

150

150

275

1753

N/A

N/A

N/A

N/A

N/A

N/A

45

110

115

230

2003

N/A

N/A

N/A

N/A

N/A

N/A

35

90

85

210

Natural Gas – 1,000 BTU/ft

3

, 0.60 specific gravity at 0.5 in. WC pressure drop

Propane Gas – 2,500 BTU/ft

3

, 1.53 specific gravity at 0.6 in. WC pressure drop

Table H: Maximum Equivalent Pipe Length

Manifold Gas Pressure

(High Fire Values)

Model

No.

Natural Gas

Propane Gas

503

-0.1

-0.1

753

-0.4

-0.1

1003 -0.8

-0.2

1253 -1.6

-0.2

1503 -2.4

-0.6

1753 -0.4

-0.1

2003 -1.0

-0.5

NOTE: Manifold pressures should be ±0.2 in. WC.

Table I: Manifold Gas Pressure Settings