Raypak 135A User Manual

Page 18

BURNER DRAWER REMOVAL

1. Shut off power and gas supply to the heater. Dis-

connect union(s) and pilot tubing when present;

then loosen and remove burner hold down screws.

2. Disconnect wires at gas valve and slide burner

drawer out.

MAIN BURNER AND ORIFICE REMOVAL

1. Remove screws and burner hold down bracket.

NOTE: If the heat exchanger is sooted badly, the burner

hold down bracket and spacer can become distorted

from direct flame impingement and this usually necessi-

tates replacement of these parts.

2. Lift burners from slotted spacer and slide from

orifices. Clean with a wire brush.

3. Orifices usually do not need to be replaced. To

clean, run either copper wire or wood through

orifice. Do not enlarge hole. To remove orifice, use

a socket wrench and remove the manifold. DO

NOT overtighten when reinstalling.

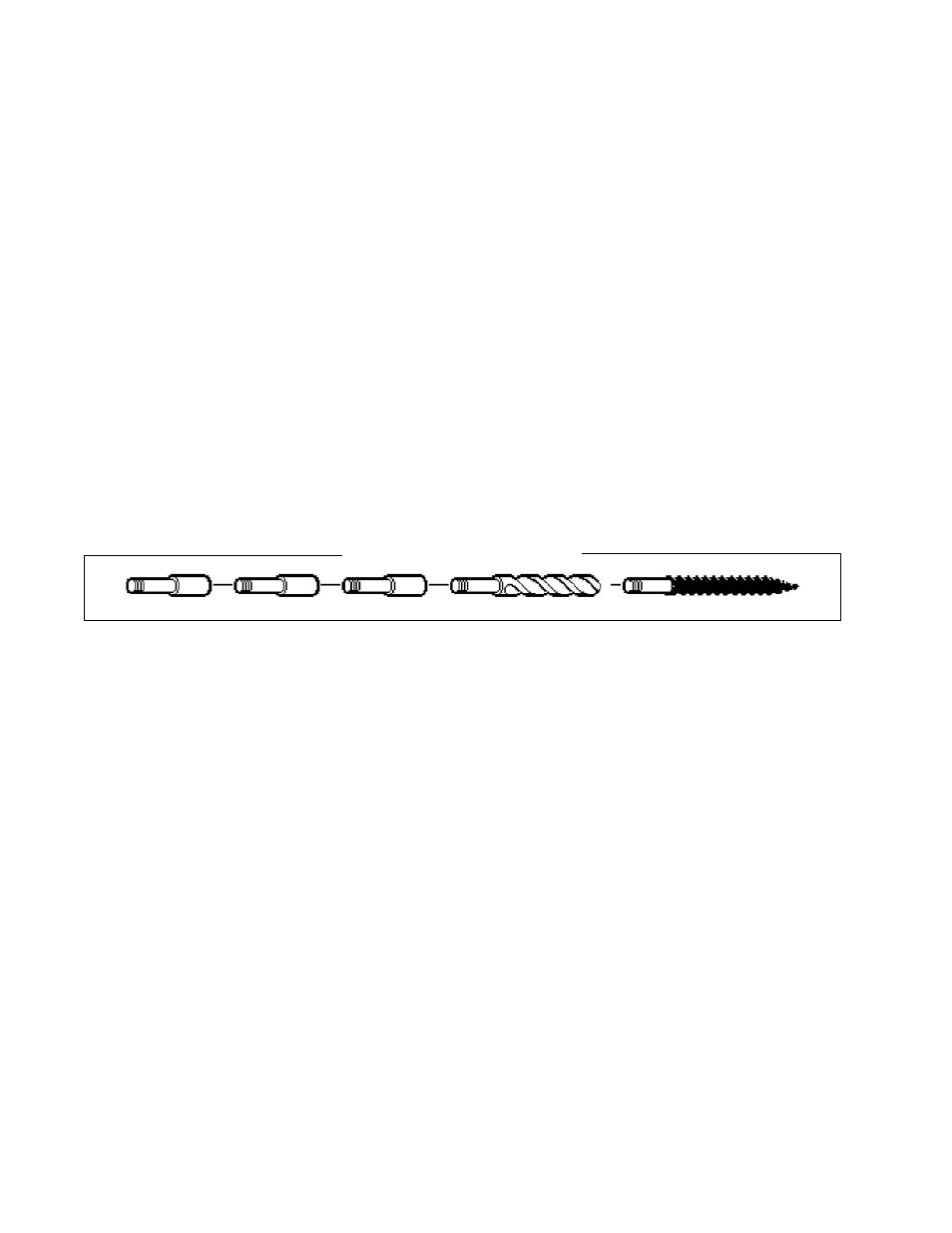

RAYPAK TUBE CLEANING KIT

Extension Pieces (5)

Auger with Carbide Tip

Wire Brush

Fig. #8185

REPAIR SECTION

TUBE CLEANING PROCEDURE (TYPICAL)

Establish a regular inspection schedule, the fre-

quency depending on the local water condition and

severity of service. Do not let the tubes clog up solidly.

Clean out deposits over 1/16" in thickness.

The heater may be cleaned from the side opposite

the water connections as shown, without breaking pipe

connections. It is preferable, however, to remove both

headers for better visibility through the tubes and to be

sure the residue does not get into the system.

Note that you do not remove the top pan or the heat

exchanger generally.

After reaming with the auger, mount the wire brush

and clean out the debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-inhibited

de-scale solvent.

HEAT EXCHANGER REMOVAL

1. Shut water, gas and electricity off, close valves and

relieve pressure, remove relief valve. Remove side

inspection panels.

2. Remove top holding screws.

3. Remove draft diverter, lift and remove top and flue

collector on stack type models. Remove inspection

panels.

4. Loosen bolts and disconnect flange nuts on inlet-

outlet header, loosen union(s) at gas pipe, and slide

heater away from piping until studs clear the heater.

5. Remove heat exchanger corner brackets.

6. Remove combustion chamber clips at the four

corners of the heat exchanger.

7. Lift heat exchanger straight up using caution not to

damage refractory.

18

PROCEDURE FOR CLEANING FLUE GAS

PASSAGE-WAYS

Soot will clog areas behind fins and cause eventual

tube failure. Any sign of soot at base of burners or around

outer jacket indicates a need for cleaning.

1. Lift off draft hood and flue collector by removing

bolts and screws.

2. Remove "V" baffles from heat exchanger.

3. Remove burner tray, see Burner Drawer Removal.

4. Take garden hose and wash heat exchanger, mak-

ing sure soot is removed from between fins.

(Avoid excessive water against refractory).

5. Reassemble; when heater is fired, some steam will

form from wet refractory. This is normal.

NOTE: In extreme cases it may be necessary to remove

the heat exchanger completely for cleaning. The sim-

plest method is steam cleaning at a local car wash. DO

NOT WIRE BRUSH!

CAUTION:

Soot is combustible, so exercise extreme care.