Gas piping – Rinnai RL75E User Manual

Page 20

20

VB Series Outdoor LS Manual

Pipe Sizing Procedure - Example

Pipe Size (inches)

3/4

1

1 1/4

1 1/2

10

273 514 1060

1580

20

188 353 726 1090

30

151 284 583 873

40

129 243 499 747

50

114 215 442 662

60

104 195 400 600

70

95 179 368 552

80

89 167 343 514

90

83 157 322 482

100

79 148 304 455

125

70 131 269 403

150

63 119 244 366

175

58 109 224 336

200

54 102 209 313

Length

Length

Pipe Size (inches)

1/2 3/4 1 1

1/4

10

291 608 1150

2350

20

200 418 787 1620

30

160 336 632 1300

40

137 287 541 1110

50

122 255 480 985

60

110 231 434 892

80

101 212 400 821

100

94 197 372 763

125

89 185 349 716

150

84 175 330 677

175

74 155 292 600

200

67 140 265 543

Gas Piping

The gas supply must be capable of handling the entire gas load at the location. Gas line sizing is based on gas

type, the pressure drop in the system, the gas pressure supplied, and gas line type. For gas pipe sizing in the

United States, refer to the National Fuel Gas Code, NFPA 54. For Canadian gas pipe sizing, refer to the Natural

Gas and Propane Installation Code CAN/CSA B149.1. The below information is provided as an example. The

appropriate table from the applicable code must be used.

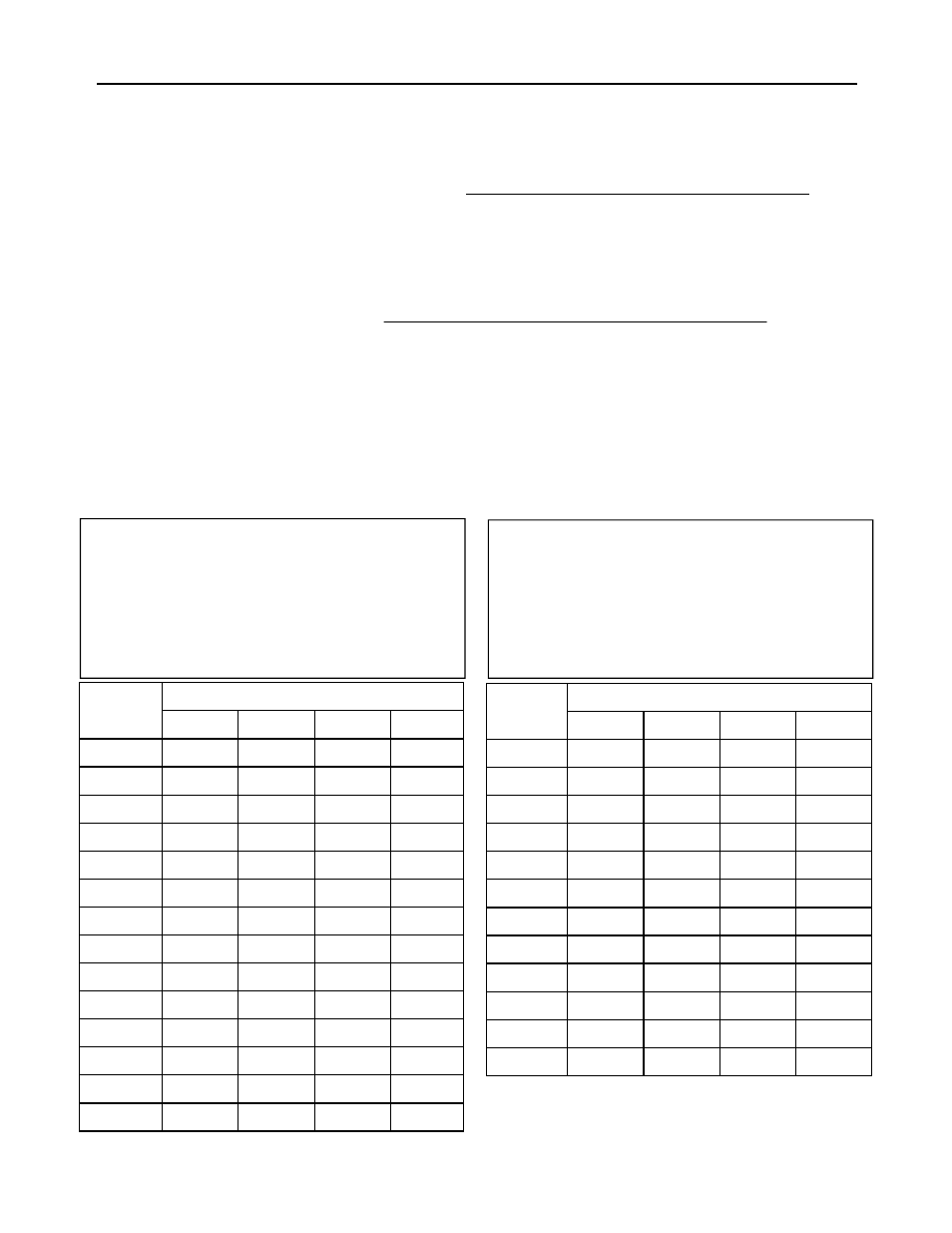

Pipe Sizing Table - Natural Gas

Pipe Sizing Table - Propane Gas

Inlet Pressure: less than 2 psi (55 inches W.C.)

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

Schedule 40 Metallic Pipe

cubic feet per hour

Schedule 40 Metallic Pipe

Capacity in Thousands of BTU per Hour

1.For some tables, you will need to determine the cubic feet per hour of gas required by dividing the gas input by

the heating value of the gas (available from the local gas company). The gas input needs to include all gas

products at the location and the maximum BTU usage at full load when all gas products are in use.

Gas

Input

of

all

gas

products

(BTU

/

HR)

Cubic Feet per Hour (CFH) =

Heating

Value

of

Gas

(BTU

/

FT

3

)

2.Use the table for your gas type and pipe type to find the pipe size required. The pipe size must be able to

provide the required cubic feet per hour of gas or the required BTU/hour.

Example: The gas input of the RL94e is 199,000 BTU/HR using propane. Additional appliances at the location

require 75,000 BTU/hr. Therefore the maximum BTU usage will be 274,000 BTU/hr.

If using propane gas with Schedule 40 metallic pipe, 100 ft in length, then the 1 inch pipe size will be

capable of supplying 372,000 BTU/hr of propane gas..