Maintenance instructions, Accessories for threading by close-coupled method, Oil system maintenance – RIDGID 1822-I User Manual

Page 21: Spindle bearing lubrication, Front jaw insert and centering finger replacement

Ridge Tool Company

19

Pipe Support Stands

No. 819 Nipple Chuck (Right Hand Only)

No. 839 Adapter Kit

Pipe Adapters..............

1

/

8

″

through 1

1

/

2

″

Stud Adapters..............

1

/

4

″

through 2

″

UNC

1

/

4

″

through 1

1

/

2

″

UNF

Accessories For Threading

By Close-Coupled Method

No. 241 Carriage Mount Kit

No. 141 Geared Threader….for threading

2

1

/

2

″

- 4

″

pipe

Pipe Support Stand

NOTE! See Ridge Tool catalog for complete list of pipe

supports, thread cutting oil and dies.

Maintenance Instructions

WARNING

Make sure machine is unplugged from power

source before performing maintenance or mak-

ing any adjustment.

Oil System Maintenance

Periodic cleaning of oil reservoir and filter screens will

promote proper operation of machine. Replace cutting oil

when it becomes dirty or contaminated.

1. Remove and clean top chip pan screen.

2. Remove and clean secondary screen from chip pan.

3. Remove drain plug and drain cutting oil.

4. Clean oil filter screen and remove sludge built up in oil

reservoir.

DO NOT operate machine with oil filter in

bottom of oil reservoir removed. This could cause chips to

clog oil line and/or damage the oil pump.

NOTE! RIDGID Thread Cutting Oil produces high qual-

ity threads and maximizes die life. For informa-

tion concerning its use and handling, refer to the

labels on the oil containers. Disposal of the oil

should be in accordance with government reg-

ulations.

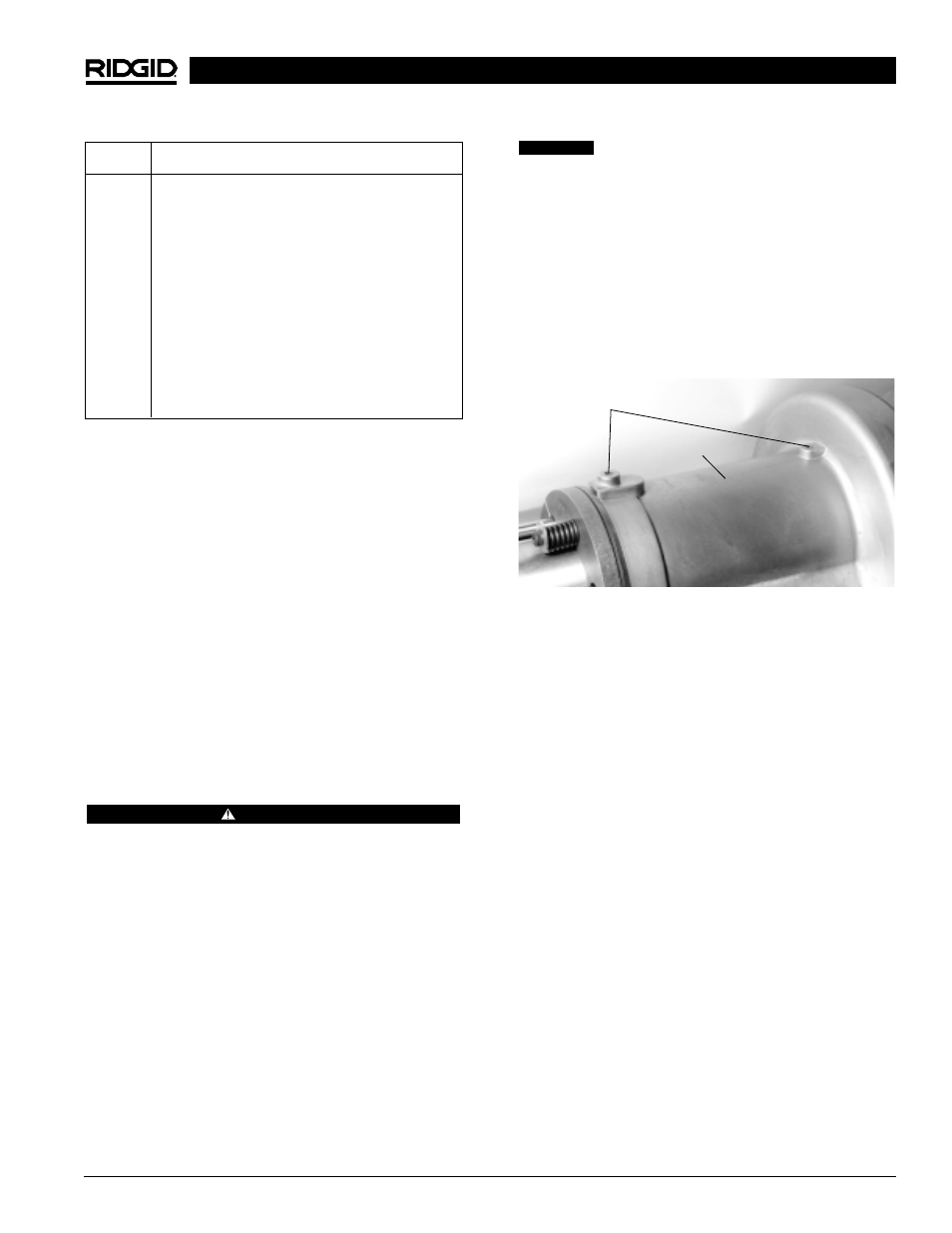

Spindle Bearing Lubrication

(Figure 22)

Figure 22 – Spindle Bearing Lubrication

Main spindle bearing lubrication ports are located on top

and at each end of the spindle housing.

Bearings are oil impregnated when manufactured and

will serve to lubricate spindle until scheduled mainte-

nance is performed.

Lubrication with 10 drops of SAE 20 Weight Nondetergent

oil is recommended every six months (more often under

heavy machine usage).

Front Jaw Insert and Centering Finger

Replacement

1. Run machine in the OPEN position to open jaws.

2. With machine OFF and unplugged, remove front

cover.

3. Loosen screw that holds jaw insert and centering

finger in place. This should allow jaw insert to separate

from jaw assembly. (Figures 23A & B)

4. On a workbench, drive out top pins holding centering

finger in place and install new centering finger.

NOTE! When driving pin out on workbench, do not bend

centering finger.

1822-I Pipe and Bolt Threading Machine

Model

No.

Description

819

Nipple Chuck 1/2

″

- 2

″

NPT

819

Nipple Chuck 1/2

″

- 2

″

BSPT

839

Adapter Kit for No. 819 Nipple Chuck

821

Blade Type Cutter

822

Adapter Kit for No. 821 Blade Cutter

141

4

″

Geared Threader NPT

141

4

″

Geared Threader BSPT

241

Carriage-Mount Kit for No. 141 Threader

1460

Oil Pan Cover Kit

E-863

L.H./R.H. Reamer Cone

364

Wheel Type Cutter

Conversion Kit for Plastic Coated Pipe

Grooving Tool

E-1050

Saran Tool for 821

D471

45° Bevel, Cut-Off Tool for 821

344

Reamer

Gear Grease (1224 & 1822)

CAUTION

Spindle Housing

Bearing Lubrication

Ports