Raypak HI DALTA HD101 User Manual

Page 25

25

Venting Installation Tips

Support piping:

·

horizontal runs- at least every five (5) feet.

·

vertical runs - use braces:

·

under or near elbows

Follow items listed below to avoid personal injury or

property damage.

·

Cut nonmetallic intake pipe with fine-toothed hack-

saw.

·

Do not use nonmetallic intake pipe or fittings that

are cracked or damaged.

·

Do not use nonmetallic intake fittings if they are

cut or altered.

·

Do not drill holes, or use screws or rivets, in non-

metallic intake pipe or fittings.

To make metallic vent joints:

·

Do not install seams of vent pipe on bottom of

runs.

·

100% Seal all joints and seams with high temper-

ature silicone sealant.

Venting Configurations

For heaters connected to gas vents or chimneys, vent

installations shall be in accordance with the section

on, Venting of Equipment, of the latest edition of

NFGC, or in Canada, B149 Installation Code for Gas

Burning Appliances and Equipment, or applicable pro-

visions of local building codes.

WARNING: Examine the venting system at least

once a year. Check all joints and vent pipe

connections for tightness, corrosion or deterioration.

NOTE: The words "Flue Exhaust", "Flue" and

"Exhaust Vent" are used interchangeably.

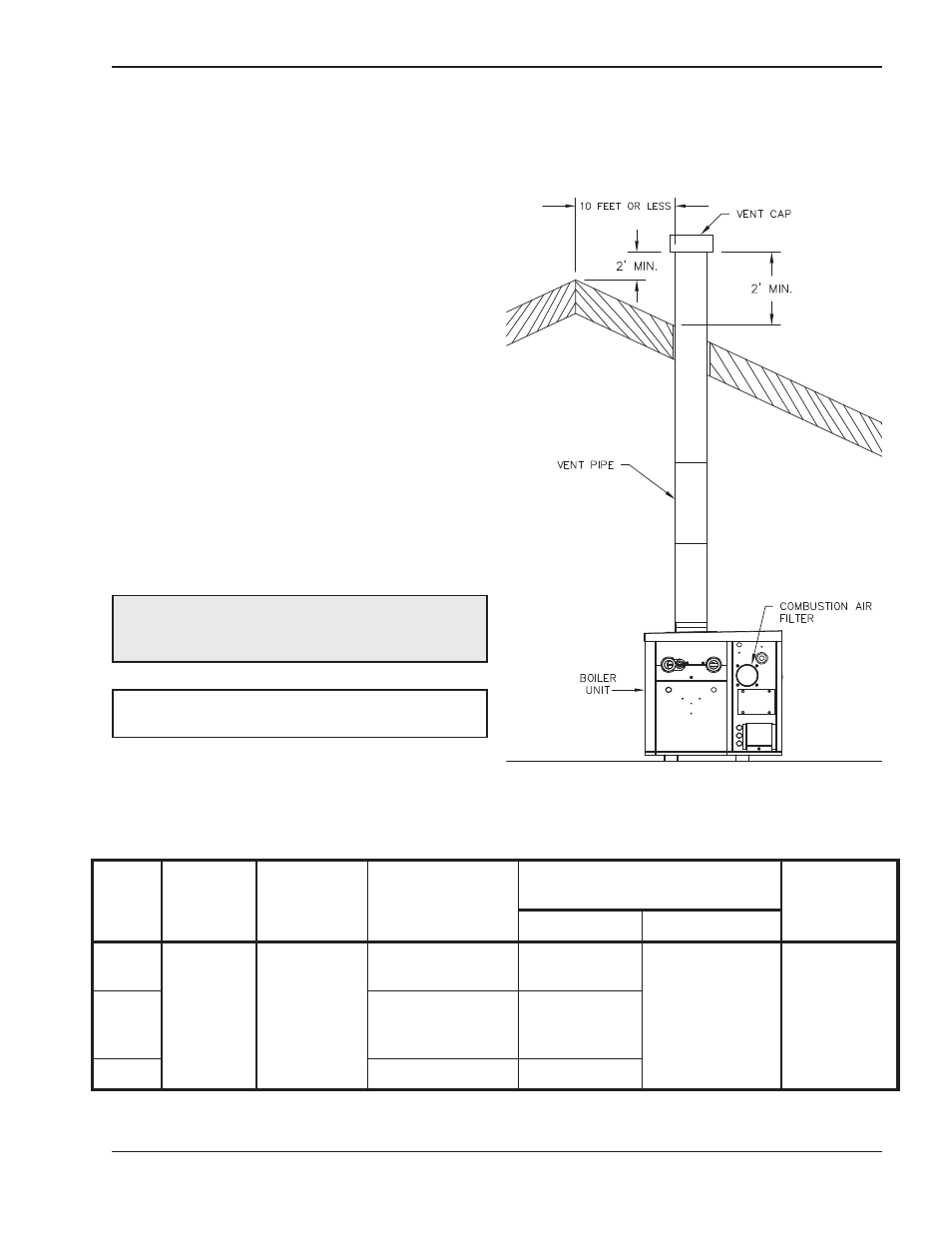

Fig. 19: Natural Draft Vertical Venting (Category I)

Model

No.

Appliance

Category

Certified

Venting

Material

Minimum

Recommended

Vent Size (inches)

Min./Max. Venting Length without

Barometric Damper (feet)**

Air Inlet Max.

Length (feet)

Min.

Max.

HD101

HD151

I

Type B or

Equivalent

4

6

25

100

HD201

HD251

HD301

5

(HD201) 6

(HD251) 6

(HD301) 11

HD401

6

8

**Vent lengths are based on a lateral length of 2 feet. Refer to the latest edition of the NFGC for further details. (ANSI Z223.1)

Table K: Natural Draft Vertical Venting