Operation manual guardshield safe 4, Attention – Rockwell Tools GUARDSHIELD SAFE 4 User Manual

Page 15

Operation Manual

GuardShield Safe 4

15

Important information:

Safety devices for connection of GuardShield Safe 4 must

be built with PNP logic. The outputs will be periodically

controlled for short-circuit and cross-fault detection.

The output voltage at the solid-state outputs is

dependant on the power supply and the output load

(see chapter 11 Technical Data).

5.3.6. Trouble shooting

Possible errors and operation status are indicated with

the LED indicators on the transmitter and receiver.

Following combinations are relevant:

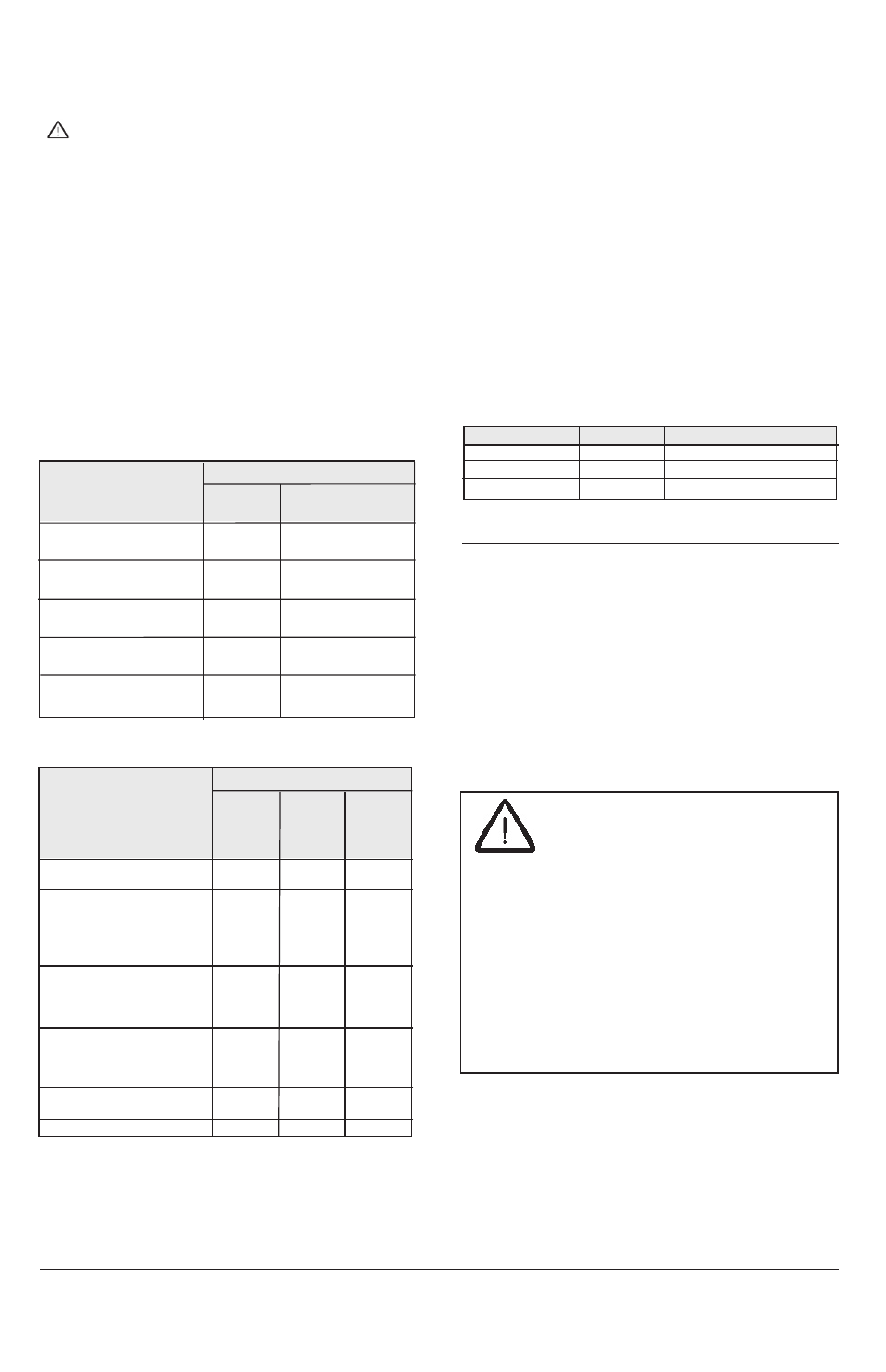

Table 1: Transmitter

Status

LED

Orange Green

Red

(Power)

(ok)

(Test)

No power supply

off

off

on

(external)

Test input closed

on

on

off

(external)

Test input open

on

off

on

(external)

Controller error

flashing

off

on

(internal)

Protective field error flashing

off

flashing

(internal)

Table 2: Receiver

Status

LED

Orange Green

Red

(Power)

(Protective (Protective

field not

field

interrupted) interrupted)

No power supply

off

off

off

(external)

No sufficient power

on

off

off

(external)

OSSD on (on-load operation,

on

on

off

protective field not interrupted,

normal)

OSSD off (off-load operation,

flashing

off

on

protective field interrupted or

insufficient alignment of the

system)

OSSD error (external, short

all 3s

circuit between OSSD 1 and

short time

off

flashing

OSSD 2, towards 0 V and off

24 VDC)

Controller error (internal)

irregular

off

on

flashing

Protective field error (internal)

flashing

off

flashing

External error: An external interface error can be

resolved by correcting the installation, due to

1.

Receiver: short circuit of both OSSDs, of OSSD

to U

sp

, of OSSD to GND

2.

Transmitter: Test input open

3.

None or too low power supply

4.

Inadequate adjustment of transmitter and

receiver

Internal error (orange LED is irregularly flashing):

Please

contact

the

nearest

ROCKWELL

AUTOMATION representative.

Normal operation

Transmitter

Receiver

Operation status

Test input closed

OSSD on

Protective field free

Test input closed

OSSD off

Protective field interrupted

Test input open

OSSD off

Test active

6. Interfacing to safety devices

The interfacing of the light curtain with the machine

control has to be control reliability, i.e. a correct

interface with a safety PLC or safety relays with

positive guided relay contacts.

Figure 17 - Diagram for automatic reset mode -

shows a diagram of a typical emergency stop relay

component.

Other applications are mentioned in the application

note “Safety Interfaces with GuardShield Safe 4”, on

the ROCKWELL AUTOMATION homepage.

ATTENTION

The safety devices and the interconnection to

the machinery have to comply with the basic

safety requirements as mentioned in the current

regulations and standards.

Direct interfacing of a safety light curtain to

machine control that does not meet the necessary

safety integrity level, i.e. use of general purpose

PLCs or general purpose relays can cause serious

injury or death of persons.

If necessary, consult a professional safety

engineer!