Preparation, Installation – NuTone NS6500 Series User Manual

Page 3

3

PreParation

1. Use the dimensional drawings (refer to FiGures 1 - 3) to lay

out the range hood’s mounting holes, wiring access and duc

-

twork by marking the cabinet bottom and drywall where appli

-

cable. NOTE: Cabinets with recessed bottoms will require wood

shims to make mounting surface flush with cabinet frame.

2. Make cutouts for wiring and ductwork.

3. If the hood is to be ducted, install the ductwork so that is flush

to the range hood’s mounting surface.

refer to FiGure 1 if the range hood is to be installed with a

horizontal discharge.

refer to FiGure 2 and FiGure 3 if the range hood is to be

installed with a vertical discharge.

4. Run two-conductor wire (with ground) from a power source to

the hood location. Bring approximately 12” of wiring through

wiring hole in cabinet.

5. Drill four 3/32” diameter pilot holes at points where mounting

holes are marked in cabinet bottom.

6. Insert four (4) mounting screws, leaving approximately ¼” of

thread exposed.

7. Remove and retain the mounting screws securing the 3¼” x

10” and 7” duct transitions to the hood. Install the appropriate

duct transition as described in the installation section.

installation

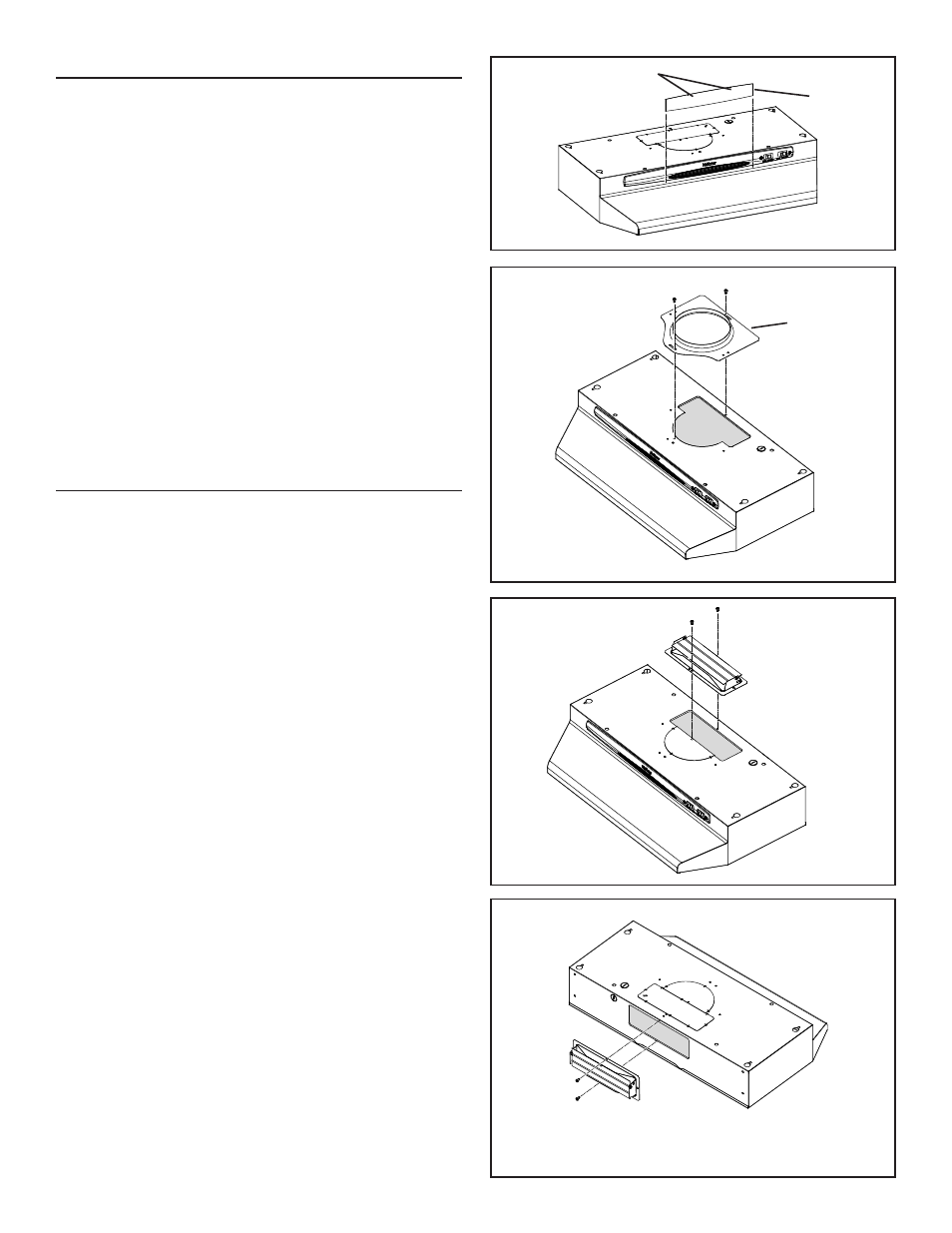

1. Remove the necessary duct opening and wiring knockout from

the range hood.

if the range hood is to be installed as a non-ducted unit,

remove the wiring knockout only.

if the range hood is to be installed as a ducted unit,

a baffle

plate is provided to close off the non-ducted vent. Install baffle

plate (refer to FiGure 4) by sliding into place behind grille.

Use locator bumps to orient in grille.

2. For 7” round discharge installation, refer to FiGure 5. Se

-

cure 7” adapter (included) to top of hood using screws provided.

Install 7” round damper (Model 895, purchased separately).

For 3¼” x 10” vertical discharge installation, refer to FiG-

ure 6.

Secure 3¼” x 10” transition (if used) to top of hood.

For 3¼” x 10” horizontal discharge installation, refer to

FiGure 7.

If using supplied 3¼” x 10” duct transition, secure

it to the range hood. Ensure that the damper flap operates

fully and freely. If it does not, remove the damper flap or make

necessary modifications to the installation to insure full and free

operation of the damper flap.

3. Feed the wiring through the access hold and into the electrical

box.

4. Align hood’s keyhole mounting slots over the four (4) partially

installed screws.

5. Making sure the duct positions over the hood’s duct transition,

push the hood against the rear wall. Secure hood by tightening

screws.

6. Using a long blade screwdriver, reach into the discharge open

-

ing and make sure the damper flap operates freely (vertical

discharge only).

FiGure 4

FiGure 6

FiGure 5

FiGure 7

locators

BaFFle

Plate

7” round

adaPter

(included)

secure transition

With screWs

(included)

Position duct

transition in

Wall cutout

horiZontal