3 mechanical installation, Typical fuel system, Fuel filtering – Hamilton Sundstrand Company Gas Fuel Metering Valve HFG2.0 User Manual

Page 10: Mechanical installation

4 HFG2.0

USER

GUIDE

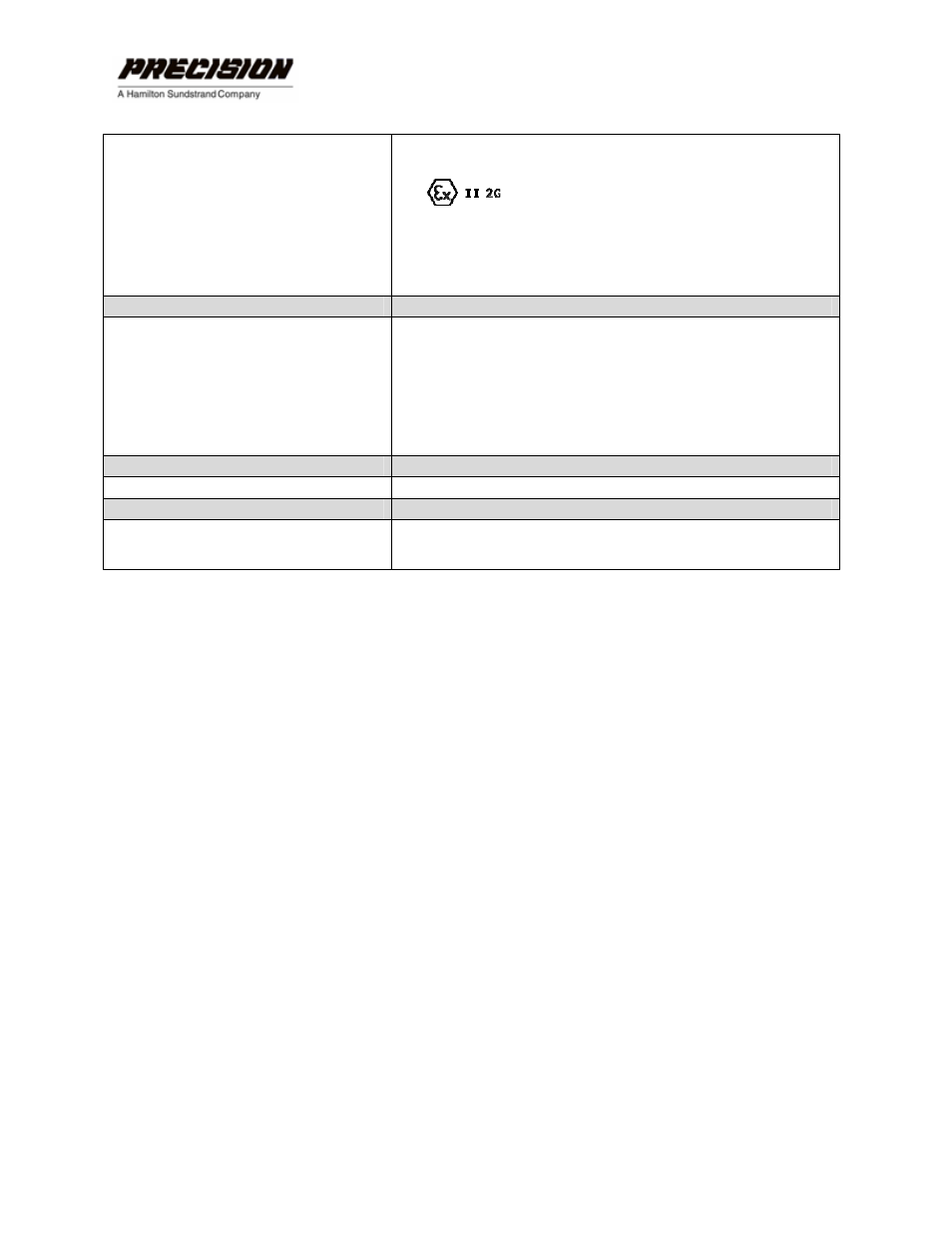

Certifications

North American Certifications

CSA Class I, Div 1, Group B, C, D; T4

European Directive Compliance (CE Mark)

EEx d, IIB+H

2

; T4

97/23/EC Pressure Equipment Directive (PED)

94/9/EC Potentially Explosive Atmospheres (ATEX) 02ATEX6051X

98/37/EC Machinery Directive

89/336/EEC Electromagnetic Compatibility Directive (EMC)

Materials

Actuator Housing

6061-T6 Anodized Aluminum

Valve Housing

6061-T6 Anodized Aluminum

316 Stainless Steel (Optional)

Conduit Union

Zinc Plated Steel

Seals

Viton and Teflon

Connectors Aluminum

Dimensions

9.7 in x7.7 in x 25.4 in

Weight

100 lbs. Max (Aluminum Valve Housing, 3-piece)

85 lbs. Max (Aluminum Valve Housing, 1-piece)

190 lbs. Max (Stainless Steel Valve Housing, 3 piece)

1.3 Mechanical Installation

This section describes proper HFG2.0 installation. Ensure compliance

with the factory recommendations.

Typical Fuel System

The HFG2.0 installs as part of a gas fuel system as shown in Figure 1-1.

In this arrangement, the HFG2.0 is located downstream from two

normally closed gas shut-off valves.

An alternate arrangement is shown in Figure 1-2. In this installation, the

HFG2.0 is located between two normally closed gas shut-off valves.

Fuel Filtering

For efficient valve operation, filter the fuel through a 40-micron absolute

filter before it reaches the valve. This extends the time between routine

maintenance. Locate the fuel filter as close as possible to the valve

INLET.