Maintenance, Clutch system – Polaris 600 HO IQ User Manual

Page 112

109

MAINTENANCE

Clutch System

n

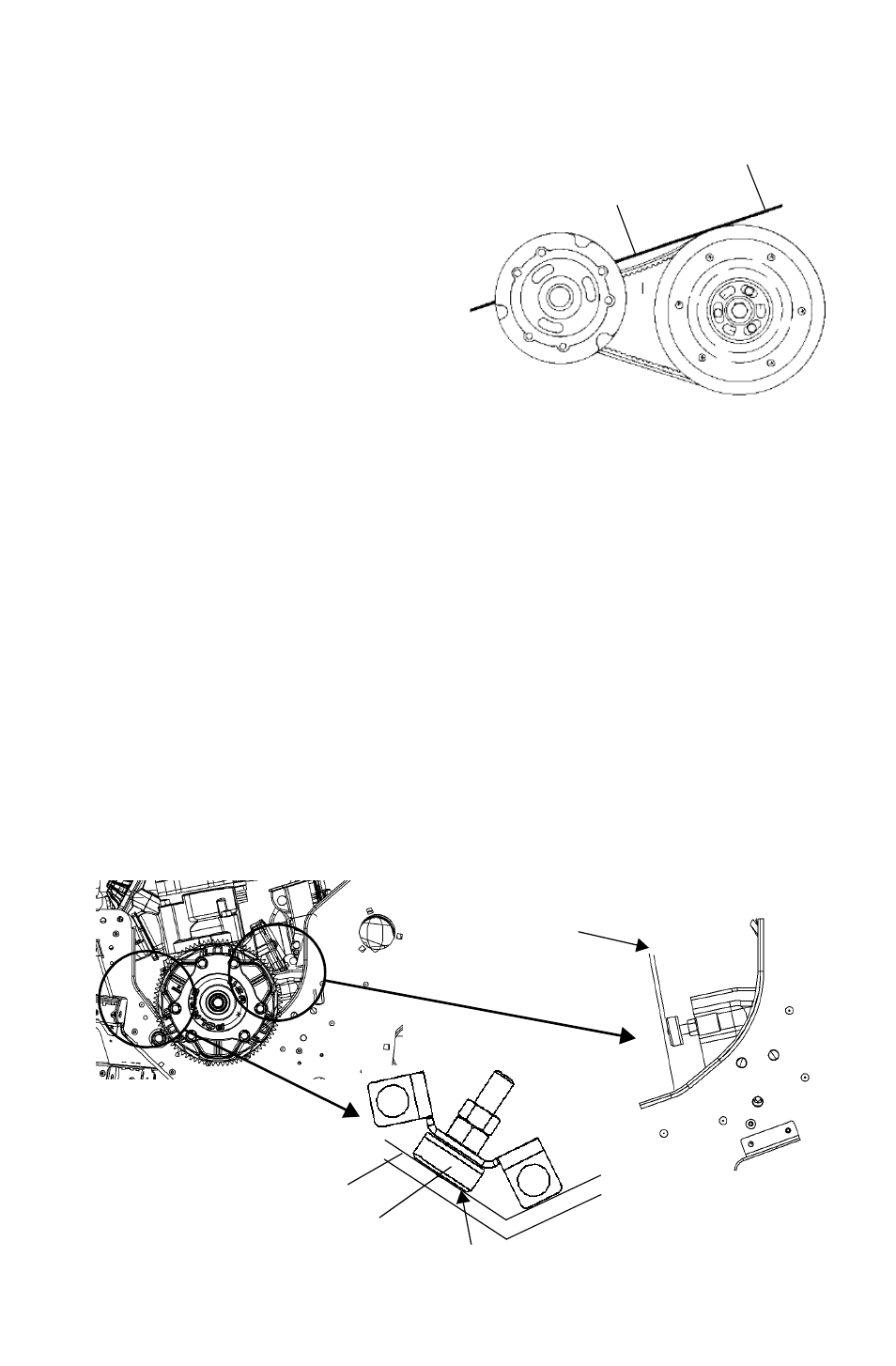

Drive Belt Deflection

Measure belt deflection with both

clutches at rest and in their full

neutral position.

Place a straight edge (1) on the

belt and apply downward pressure

while measuring at point 2. This

measurement should be 1 1/4I

(3.2 cm).

Drive Belt Adjustment

TEAM Clutch

1. Install the L-wrench into the open threaded hole in the outer sheave

of the clutch (see page 107). Turn the wrench clockwise slightly to

remove pressure from the sheaves.

2. Loosen the 7/16I jam nut.

3. Using a 1/8I Allen wrench, turn the set screw inward (clockwise) to

increase the distance between the sheaves or outward (counter-

clockwise) to decrease the distance.

4. Tighten the jam nut. Store the L-wrench in the tool kit.

Torque Stop

Periodically check torque stop clearance. With clutches in proper align-

ment, measure rear torque stop clearance from the engine case. Measure

front torque stop clearance from the bracket when the isolator is bot-

tomed out on the bracket. The clearance for both torque stops should be

.010I-.030I (.25-.75mm). Adjust if necessary. Lock the jam nut.

1

2

.010

I

-.030

I

(.25-.75 mm)

Front Torque Stop

.010

I

-.030

I

(.25-.75 mm)

Bracket

Isolator

Rear Torque Stop