Operation – Porter-Cable PC305TP User Manual

Page 7

7

12A

10

OPERATION

STARTINg ANd STOPPINg PLANER

Make sure that the switch is in the "OFF"

position before plugging cord into outlet. do not touch the

plug’s metal prongs when unplugging or plugging in the

cord.

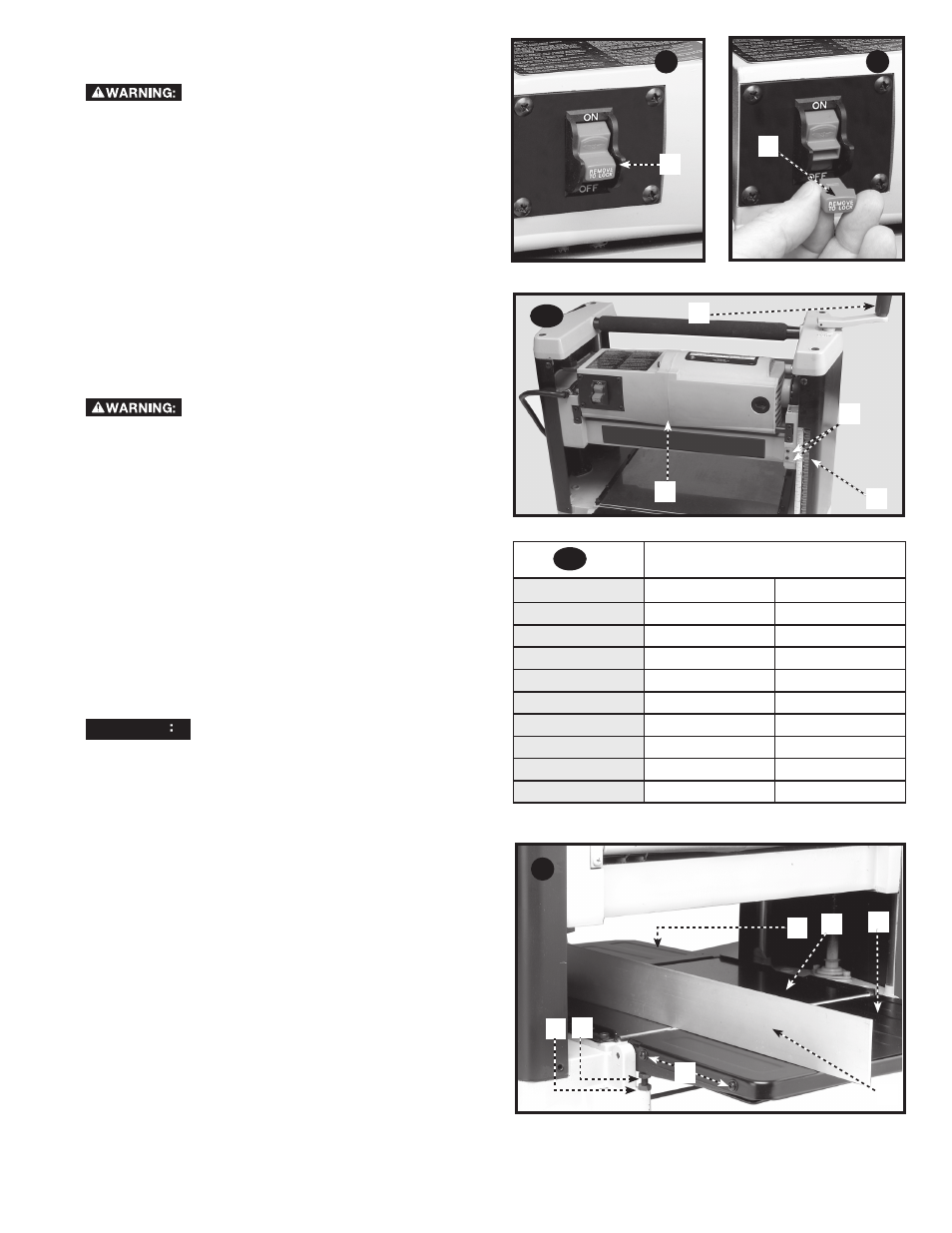

1. The on/off switch (A) Fig. 10 is located on the front of the

planer moter. To turn the machine

"ON", move the switch

up to the

"ON" position.

2. To turn the machine

"OFF", move the switch (A) down to

the

"OFF" position.

LOCKINg SWITCH IN THE "OFF" POSITION

IMPORTANT: When the machine is not in use, the switch

should be locked in the "OFF" position to prevent

unauthorized use. To lock the machine, grasp the switch

toggle (T) and pull it out of the switch (Fig. 11). With the switch

toggle (T) removed, the switch will not operate. However, should

the switch toggle be removed while the planer is running, the

machine can be turned

"OFF," but cannot be restarted without

reinserting the switch toggle (T).

In the event of a power outage (such as a

breaker or fuse trip), always move the switch to the "OFF"

position until the main power is restored.

RAISINg ANd LOWERINg HEAd ASSEMBLY

The head assembly (A) Fig. 12A contains the cutterhead feed

rollers, cutterhead guard and motor. Raising and lowering the

head assembly controls the depth-of-cut on your planer. To

raise or lower the head assembly, rotate the handle (D).

NOTE: One revolution of the handle will move the cutterhead

up or down approximately 5/64 inch (2 mm).

An English/metric scale and pointer (C) is located on the front of

the planer to indicate the height of the cutterhead. Adjustment

to the pointer can be made by running a piece of wood through

the machine. Measure the thickness of the workpiece and if

an adjustment is necessary, loosen two screws (B) and adjust

pointer accordingly. Then tighten two screws.

Refer to Fig. 12B for recommended maximum depth-of-cut for

various board widths of soft and hard woods.

NOTICE

AVIS

AVISO

fr

sp

Continuous operation at the deepest depth

of cut can cause premature motor failure.

A

A

C

D

B

12B

LEVELINg EXTENSION TABLES

The extension tables (A) and (G) Fig. 14 must be level with

the planer table. To check the extension tables and adjust if

necessary:

1. Place a straight edge (B) Fig. 14 on the planer table (E) with

one end extending out over the infeed table (A). Check to

see if the infeed table is level with the planer table on both

ends of the planer table.

2. If an adjustment is necessary, loosen the locknut (C)

Fig. 14, and adjust the stop screw (D) on each side of

the infeed table (A) until the extension table is level with

the planer table (E). Tighten the locknut (C). Recheck and

make certain that the inside edge of table extension is

level with the planer table. If necessary, loosen the two

screws (F), adjust the extension table and retighten the

two screws (F). Adjust the opposite side of the table in

the same manner. Make certain that the extension table is

solidly supported when downward pressure on the table is

applied.

3. Check and adjust the outfeed table (G) in the same

manner.

A

B

d

C

E

g

F

14

11

T

Maximum depth-of-cut

Board Width

Soft Woods

Hard Woods

2 inches (50.8 mm)

3/32 inches (2.4 mm)

3/32 inches (2.4 mm)

4 inches (101.6 mm)

3/32 inches (2.4 mm)

3/32 inches (2.4 mm)

6 inches (152.4 mm)

3/32 inches (2.4 mm)

3/32 inches (2.4 mm)

7 inches (177.8 mm)

3/32 inches (2.4 mm)

3/32 inches (2.4 mm)

8 inches (203.2 mm)

3/32 inches (2.4 mm)

3/32 inches (2.4 mm)

9 inches (228.6 mm)

5/64 inches (2 mm)

1/16 inches (1.6 mm)

10 inches (254 mm)

1/16 inches (1.6 mm)

3/64 inches (1.2 mm)

11 inches (279.4 mm) 1/16 inches (1.6 mm)

3/64 inches (1.2 mm)

12 inches (304.8 mm) 1/16 inches (1.6 mm)

3/64 inches (1.2 mm)