It’s a screwdriver, Driving wood screws – Porter-Cable 987 User Manual

Page 13

13

2.

Start drilling with slow speed and gradually increase speed as drill cuts.

The harder the material, the slower the speed required. The softer the

material, the faster the speed.

3.

When drilling a large hole, first drill a smaller hole and then enlarge it to

the required size.

4.

The use of a lubricant, such as oil, on the drill point helps keep the bit

cool, increases drilling action, and prolongs drill bit life.

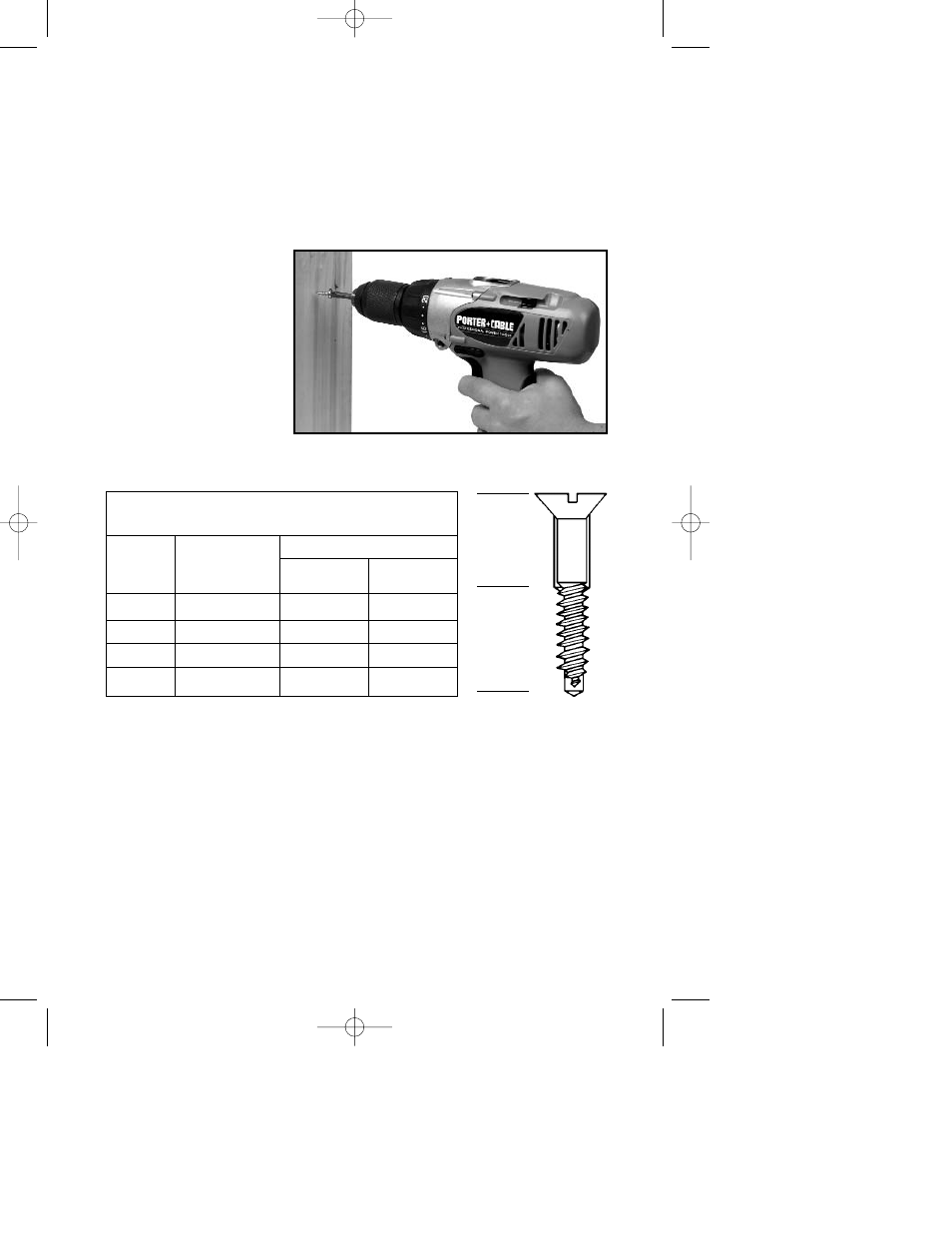

DRIVING WOOD SCREWS

1.

Drill pilot and shank clearance holes. See following chart.

2.

Install proper bit that fits screw.

3.

Set torque adjusting collar for desired torque and set speed selector to

LOW.

4.

Set screwdriver for correct rotation.

5.

Start screw straight in hole with fingers.

6.

Place bit on screw, remove fingers, start screwdriver and exert pressure.

7.

As soon as screw has seated, stop drill and lift screwdriver from screw.

8.

A lubricant, such as soap or wax, may be used on screw threads for ease

of driving. This is particularly important in hard wood.

9.

Combination pilot drill, shank drill, and countersink bits are available from

local supply houses for drilling holes in one easy operation.

IT’S A

SCREWDRIVER!

Fig. 12

Fig. 8

↑

Shank

Drill

↓

SUGGESTED HOLE SIZES

FOR WOOD SCREWS

Shank Drill

Pilot Drill Diameter

Screw

Clearance

Soft

Hard

Size

Diameter

Wood

Wood

#6

9

/

64

(.140)

1

/

16

(.062)

7

/

64

(.109)

#8

11

/

64

(.172)

5

/

64

(.078)

1

/

8

(.125)

#10

3

/

16

(.187)

3

/

32

(.094)

9

/

64

(.140)

#12

7

/

32

(.218)

7

/

64

(.109)

5

/

32

(.156)

↑

Pilot

Drill

↓

984-987 - manual - 905273- 04-08-03.qxd 4/8/03 9:41 AM Page 13