Maintenance, Lubrication guide – Polaris Scrambler 9922461 User Manual

Page 65

61

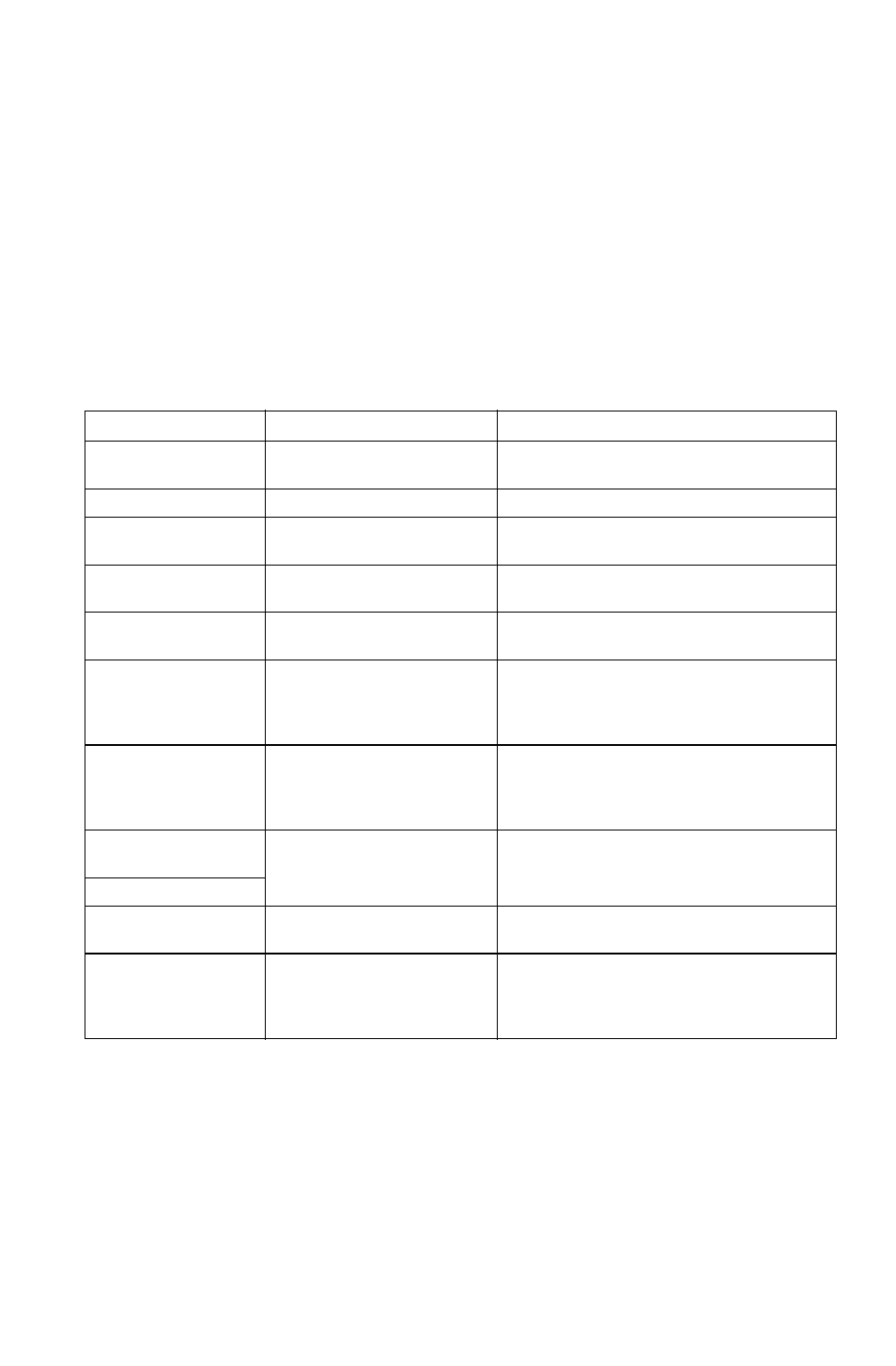

MAINTENANCE

Lubrication Guide

Check and lubricate all components at the intervals outlined in the Peri-

odic Maintenance Chart beginning on page 57. Items not listed in the

chart should be lubricated at the General Lubrication interval. See page

109 for the part numbers of Polaris products.

The a-arms and lower control arms are lubricated at the factory, and no

additional lubrication will be needed. However, if these components are

subjected to severe use, grease zerks have been provided for additional

lubrication at the user's discretion.

Item

Lube

Method

Engine Oil

PS-4 PLUS Performance

Synthetic 2W-50

See page 63.

Brake Fluid

DOT 4 Only

See page 32.

Drive Chain(s)

O-ring chain lube or SAE

80/90

Lubricate.

Transmission Oil

AGL Synthetic Gearcase

Lube

See page 68.

Demand Drive Fluid

(Front Gearcase)

Demand Drive LT

Premium Fluid

See page 70.

Front Prop Shaft

Yoke

Premium U-Joint Lube

Grease fittings (3 pumps maximum)

every 500 miles (800 km), before long

periods of storage, or after pressure

washing or submerging.

Front Hubs

Premium Hub Lube

Remove set screw in hubs. Rotate

wheels to 4 o'clock position. If lubricant

is not visible add more. Reinstall set

screw.

Swing Arm

Bushings

X

Premium All Season

Grease

Locate fittings on swing arm and

grease with grease gun

Axle Housing

Ball Joint

X

Premium All Season

Grease

Locate fitting on back side of struts and

grease with grease gun.

Tie Rod Ends

X

Premium All Season

Grease

Lift boot, clean away dirt and grease,

apply fresh grease by hand and reas-

semble. Perform when suspension

action becomes stiff, or after washing.