Troubleshooting and repair, Stator voltage test (continued) – Lincoln Electric OUTBACK SVM204-A User Manual

Page 68

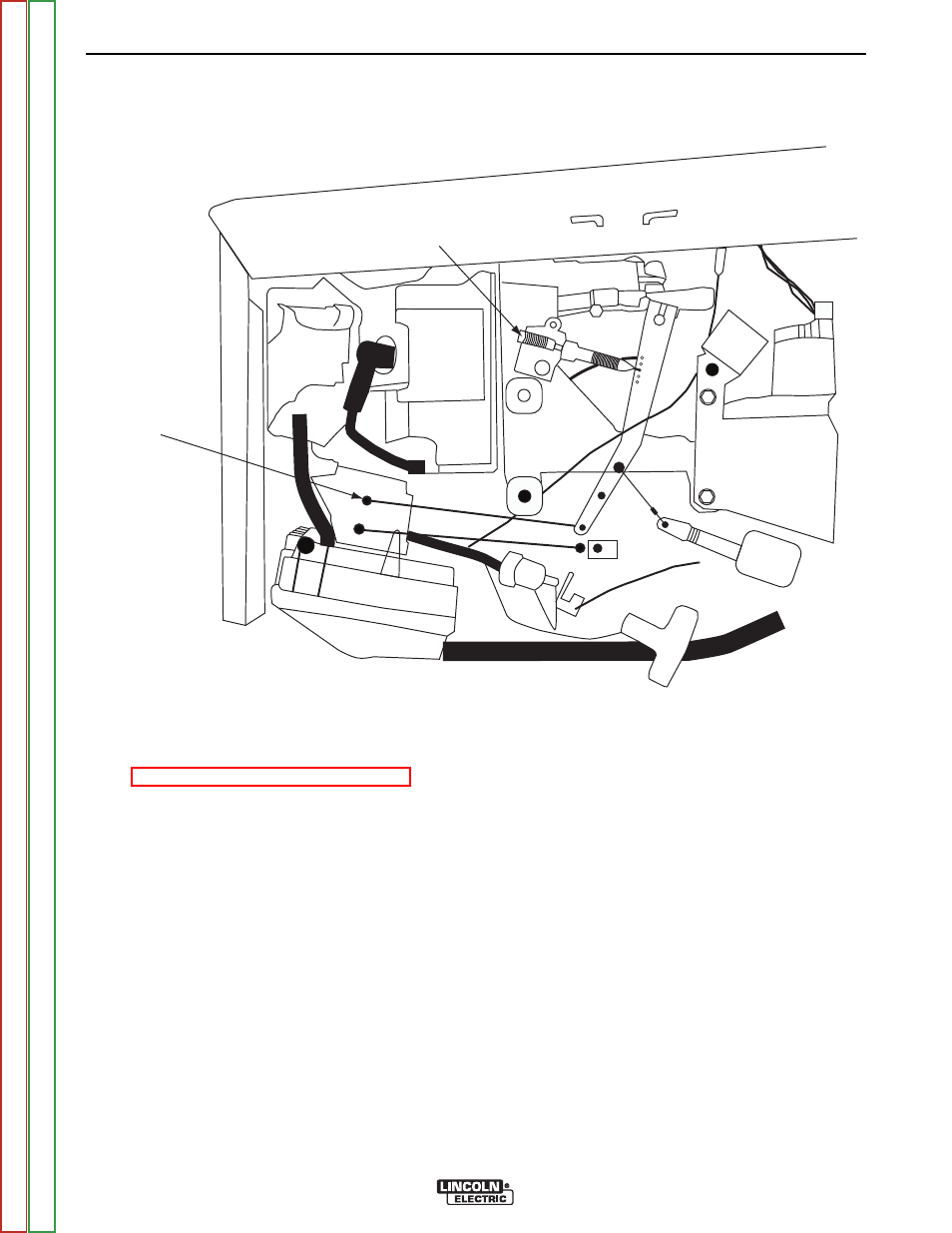

HIGH IDLE ADJUSTMENT

LOW IDLE ADJUSTMENT

TOP VIEW OF ENGINE

FIGURE F.9 – HIGH AND LOW IDLE ADJUSTMENT

STATOR VOLTAGE TEST (continued)

PROCEDURE

1. Verify that the engine RPM is normal. See the

Engine RPM Adjustment Procedure.

2. Start the machine and place the idle switch in

the high position. See Figure F.9.

3. Check for AC voltage between the neutral stud

on the control panel bottom and the #3 lead

connection at the CB1 circuit breaker. Also

check the voltage between the neutral stud and

the #6 lead connection at the CB1 circuit break-

er. Voltage should read between 115 and 130*

volts. See wiring diagram.

4. Check for AC voltage between leads W1 and

W2. See Wiring Diagram. Voltage reading

should be about 64*VAC. Also check for AC

voltage between leads W3 and W4. Voltage

reading should be about 62*VAC. See wiring

digram.

5. If the voltage is not present or is significantly dif-

ferent from expected readings, check the wiring

between test points and the stator winding. See

wiring diagram. If the wiring is in good condi-

tion, the stator is defective.

*Voltage shown is for a stator that is at normal full

load temperature. Readings will likely be slightly

higher if machine is cold.

TROUBLESHOOTING AND REPAIR

F-28

F-28

OUTBACK® 185