Troubleshooting and repair, Brush and slip ring service procedure (continued) – Lincoln Electric OUTBACK SVM204-A User Manual

Page 60

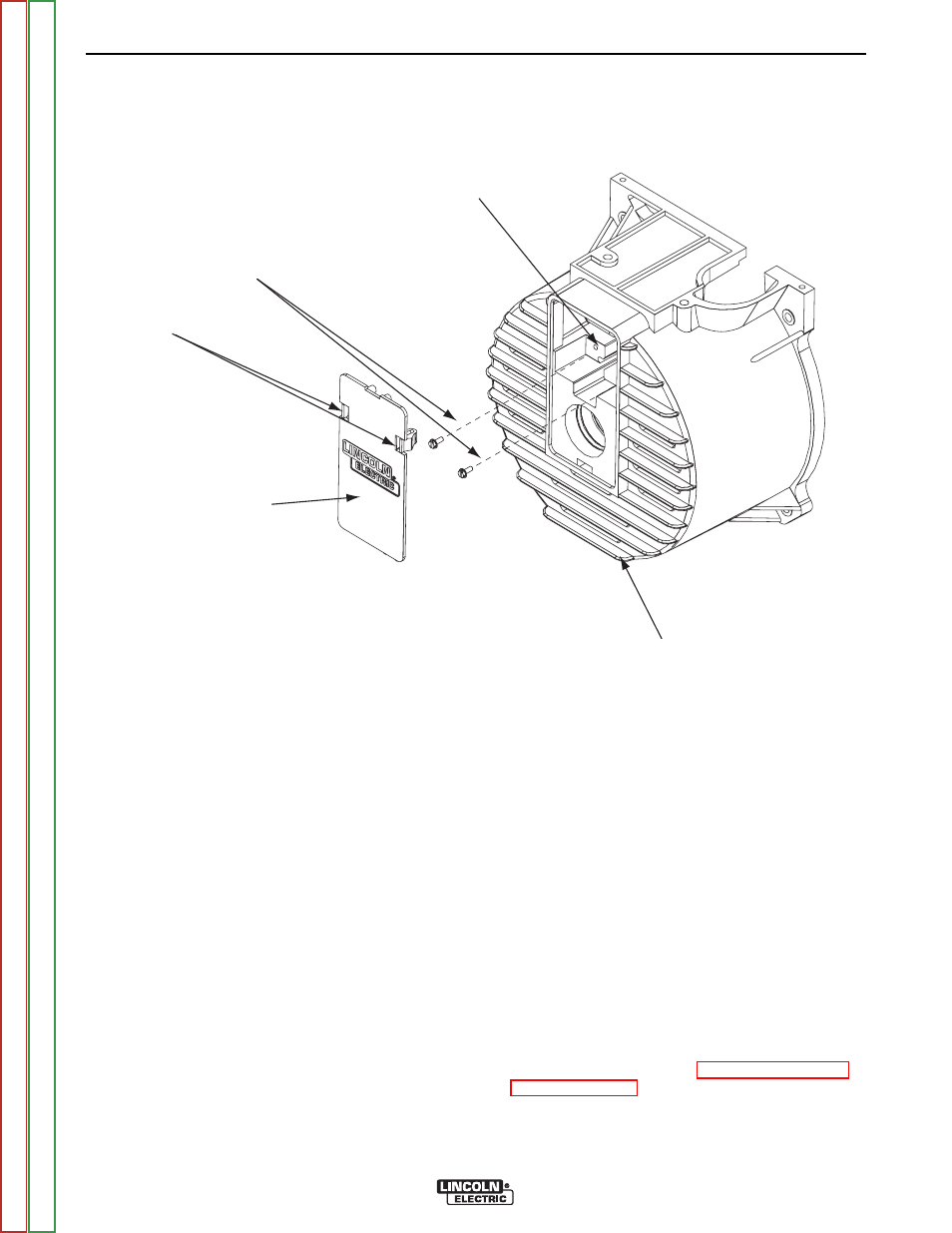

GENERATOR END BRACKET

BRUSH HOLDER ASSEMBLY

COVER

SCREWS (2)

LOCKING TABS

FIGURE F.5 – BRUSH HOLDER ASSEMBLY LOCATION

BRUSH AND SLIP RING SERVICE PROCEDURE (continued)

PROCEDURE

1. Remove the brush cover from the end of the

generator.

2. Pry outward at the top of the plastic brush cover

while depressing the two locking tabs at the

sides of the cover. See Figure F.5.

3. Remove the brush and brush holder assembly.

4. Use needle-nose pliers to remove the leads

from the brush terminals, and then use the 1/4”

nut driver to remove the two screws holding the

brush holder in place. The brush holder assem-

bly can now be pulled straight out from the end

of the generator toward the front of the

machine.

5. Examine brushes and slip rings. The slip rings,

brush holder, and brushes should be clean and

free from oil or grease. The brushes should be

making good, continuous contact with the slip

rings.

6. The brushes should be of sufficient length and

have adequate spring tension. Generally, the

brushes should be replaced if either brush has

less than 1/4” remaining before it reaches the

end of its travel. Spring tension should be suf-

ficient to hold the brushes firmly against the slip

rings.

7. The brushes should be removed from the brush

holder and be examined. The terminals should

be clean. The shunt, (braided lead connecting

the carbon brush to the terminal) should be in

good condition and firmly connected to the car-

bon brush and to the connection terminal.

8. If the slip rings are discolored, display evidence

of excessive sparking, or the brushes have

worn prematurely; these may be signs of a

grounded or shorted roter. Perform The Rotor

Resistance Test.

TROUBLESHOOTING AND REPAIR

F-20

F-20

OUTBACK® 185