Service instructions & installation tips – Lincoln Electric 500 User Manual

Page 30

D-2

MAINTENANCE

D-2

VANTAGE 500 CUMMINS

Service Instructions & Installation Tips

For Engine Air Filter

•

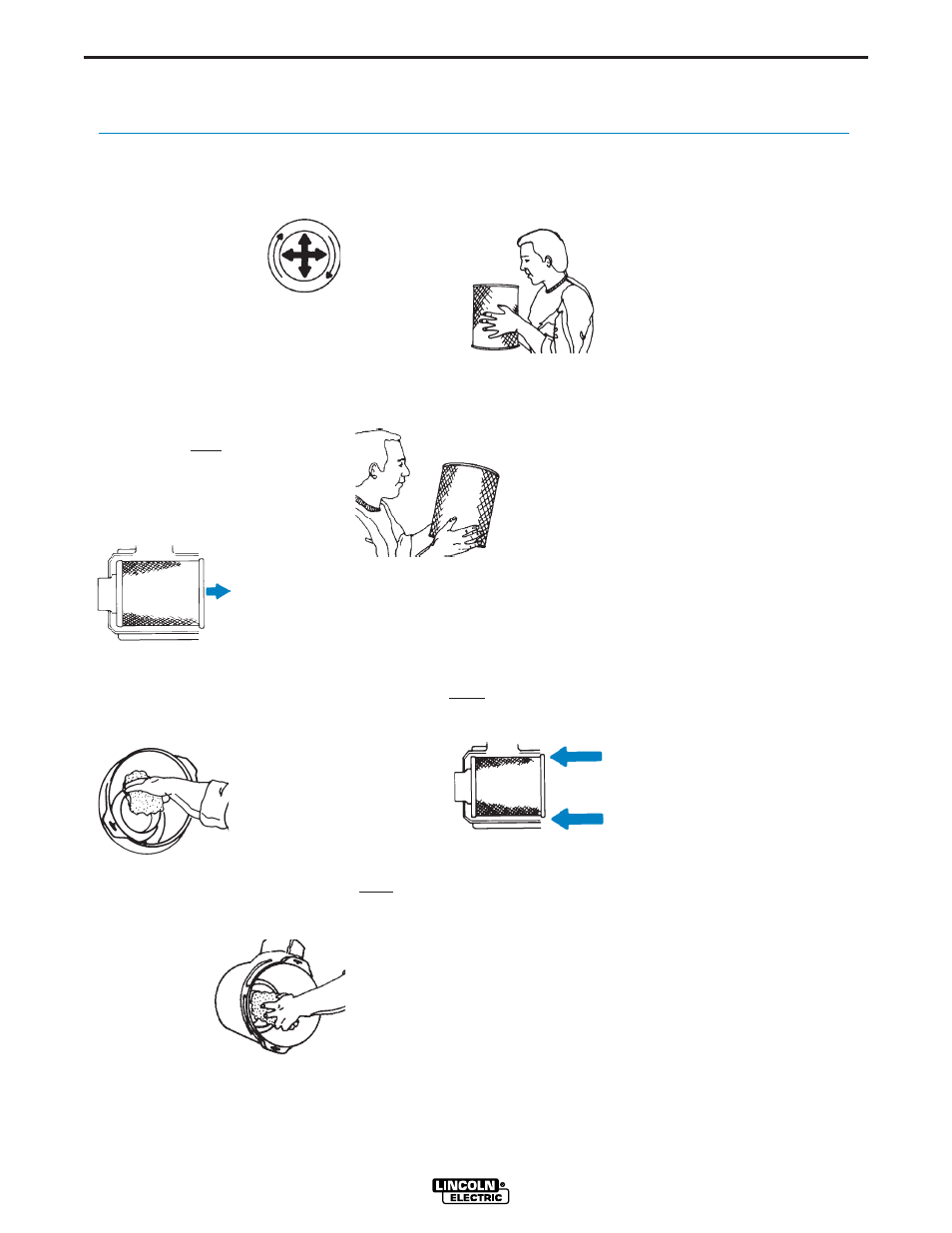

Release the

1

Seal Carefully

Unlatch and remove the service

cover of the air cleaner. Make

certain the latches are folded

back against the cover so that

they don t hinder filter

removal/installation. Most latches

are spring loaded to fold back when open.

The filter fits tightly over the outlet tube,

creating the critical seal on the inside

diameter of the filter endcap. The filter

should be removed gently to reduce the

amount of dust dislodged. There will be

some initial resistance, similar to breaking

the seal on a jar. Gently move the end of the

filter back and forth to break the seal.

Avoid Dislodging

2

Dust from the Filter

Gently pull the

filter off the outlet

tube and out of the

housing. Avoid

knocking the filter

against the housing.

Clean Sealing Surface

3

of the Outlet Tube

Use a clean cloth to wipe the sealing

surface. Dust on the outside diameter of the

outlet tube could hinder

an effective seal

and cause leakage.

Make sure that all

contaminant is

removed before the

new filter is inserted.

Insert the New

7

RadialSeal

ô

Filter

by Hand

Insert carefully. Seat the new filter by hand,

making certain it is completely into the air

cleaner housing before latching the cover in

place. If the cover hits the filter before it is

fully in place, remove the cover and push

(by hand) the

filter further into

the air cleaner

and try again.

The cover

should go on

with no extra force.

Never use the latches on the cover to force

the filter into the air cleaner! It is tempting

to assume the cover will do the job of

seating the filter but it will not! Using the

latches to push the filter in could cause

damage to the housing and will void the

warranty.

Donaldson filters with RadialSeal

“

Sealing

Technology are self-aligning, self-centering,

and self-sealing. A new filter has a dry

lubricant to aid installation. The critical

sealing area will stretch slightly, adjust

itself and distribute the sealing pressure

evenly. To complete a tight seal, apply

pressure by hand at the outer rim of the

filter, not the flexible center. (Avoid

pushing on the center of the urethane end

cap.) No cover pressure is required to hold

the seal. Again, do NOT use the service

cover to push the filter into place!

When the filter in is place, put the service

cover back on, making sure the Vacuator

“

Valve points down. Inspect the Vacuator

Valve for cracks or dust hang-ups to insure

that it is functioning properly. Re-fasten

the latches.

Check Connections

8

for Tight Fit

Make sure that all clamps, bolts, and

connections in the entire air intake system

are tight. Check for holes in piping, and

repair if needed.

Clean the Inside of

4

the Outlet Tube

Carefully wipe the inside

of the outlet tube

with a clean cloth.

Dirt accidently

transferred to the

inside of the outlet

tube will reach the

engine and cause wear.

(Engine manufacturers says that it takes

only a few grams of dirt to dust an

engine!) Be careful not to damage the

sealing area on the tube.

Check the Old

5

Filter for Leak Clues

Visually inspect the old filter for any signs

of leaks. A streak of dust on

the clean side of the filter

is a telltale sign.

Remove any cause

of leaks before

installing new

filter.

Inspect the New

6

Filter for Damage

Inspect the new filter carefully,

paying attention to the inside of

the open end,

which is the

sealing area.

NEVER install

a damaged filter.

“