Operation, B-12, Precision tig 375 – Lincoln Electric PRECISION TIG IM936 User Manual

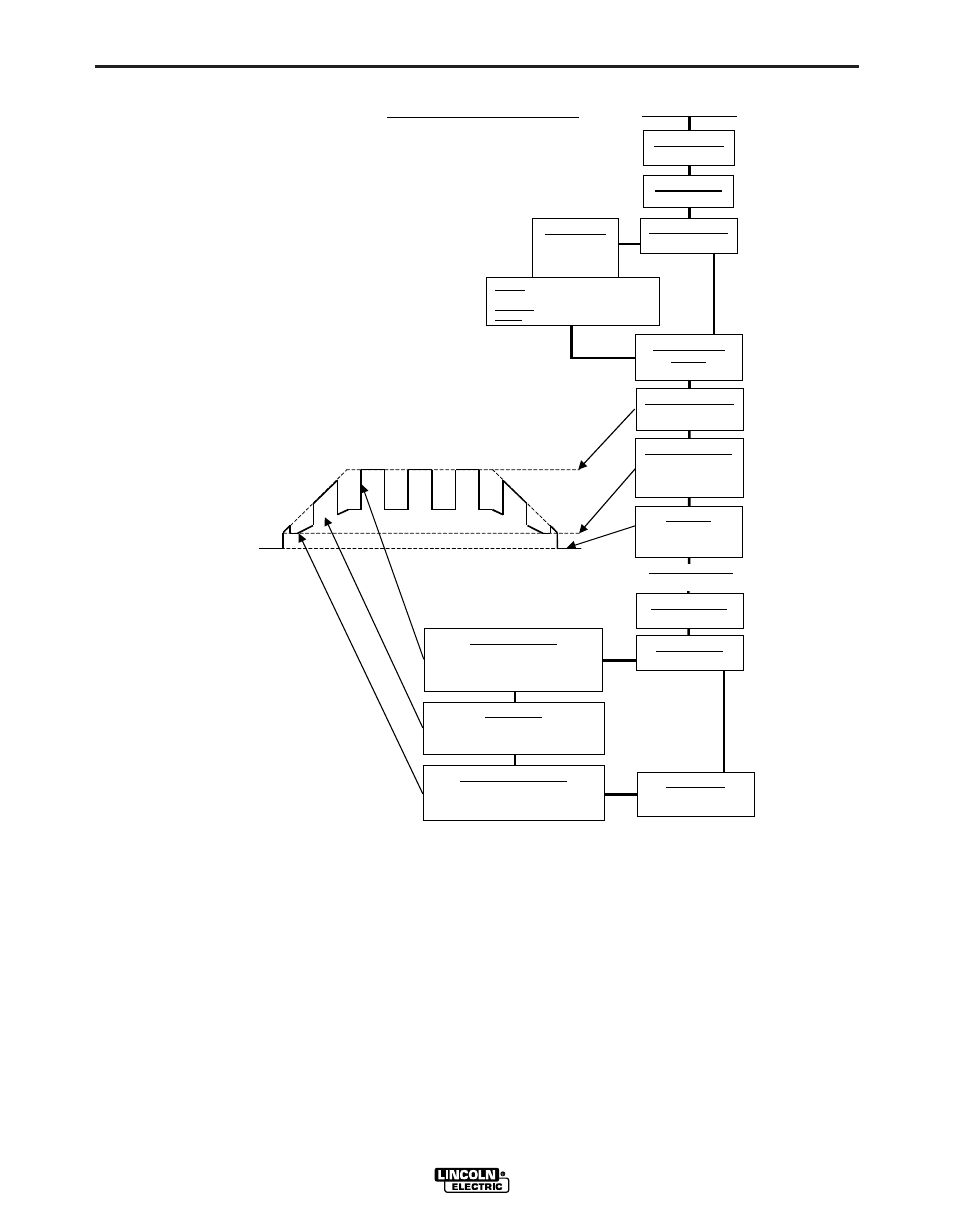

Page 27: Figure b.6

B-12

OPERATION

B-12

PRECISION TIG 375

Max. to Min.

Amptrol

Min. to Max.

Amptrol

Setup for TIG Amptrol Welding

Advanced Panel

(If used)

Standard Controls

Power Switch

ON

Polarity Switch

AC or DC

-

Mode Switch

TIG

AC Balance

AUTO

or

Set:

More + for alum.oxide "Cleaning"

w/o "Spitting" or "wetting" loss.

Balanced for equal + and - current.

More - for higher "Penetration".

Local/Remote

Switch

REMOTE

Trigger Switch

2-STEP

Pulse Switch

ON or OFF

Pulse Frequency

4-6 pps is a typical initial setting.

Set for bead shape and travel speed:

Higher for thinner plate and faster travel.

Lower for thicker plate and slower travel.

% On Time

40-60% is a typical initial setting.

Set for total heat of Peak current:

Lower reduces distortion and burn-thru.

Background Current

40-60% is a typical initial setting.

Set as low as will maintain a pulse arc

(Will not drop below Min.Output setting.)

Downslope

ZERO

For no arc-out delay.

Minimum Output

Press Display switch

and Set to desired min.

Amptrol (Start/Crater)

output level.

Postflow

Set as low as required.

Higher for larger

tungsten and current.

Maximum Output

Set to desired max.

Amptrol output level.

FIGURE B.6