Operation, Controls and settings, Warning – Lincoln Electric PRECISION TIG IM936 User Manual

Page 18

B-3

OPERATION

B-3

1. POWER SWITCH - Input line switch turns input

power ON or OFF, as indicated by the on or off sta-

tus of the front panel displays.

2. POLARITY SWITCH – The 3-position rotary power

switch has detente positions for DC-, AC and DC+

selections for the Electrode output welding polarity.

3. MODE SWITCH – The mode switch allows vertical-

ly positioned selection of the two machine welding

modes. The selected mode is indicated by a lit col-

ored panel light which permits viewing the machine

setting from a distance:

3.a STICK mode (Top position) –Red panel light

ELECTRIC SHOCK can kill.

• When the Power Source is ON in

STICK mode the Electrode circuits of

both the Stick and TIG torch cables

are electrically HOT to Work.

------------------------------------------------------------------------

• The CC Stick mode may be used for general pur-

pose stick welding (SMAW ) within the capacity of

the machine. The capacity is too limited for arc air

carbon (AAC) gouging.

• In this mode; the output terminals are activated

electrically HOT, gas flow is not activated and HOT

START and ARC FORCE levels are fixed, or

Advanced Panel selectable (See Section B-7 ), with

no front panel adjustment.

3.b TIG mode (Bottom position) – No panel light.

• When the Polarity Switch is set to AC, the TIG

mode provides continuous high frequency to stabi-

lize the arc for AC TIG welding.

Hi-Freq. turns on after preflow time with the arc

start switch closure, and turns off when the arc

goes out* after the arc start switch opens.

* Arc voltage and current are sensed to determine if

the arc is established or out.

PRECISION TIG 375

CONTROLS AND SETTINGS

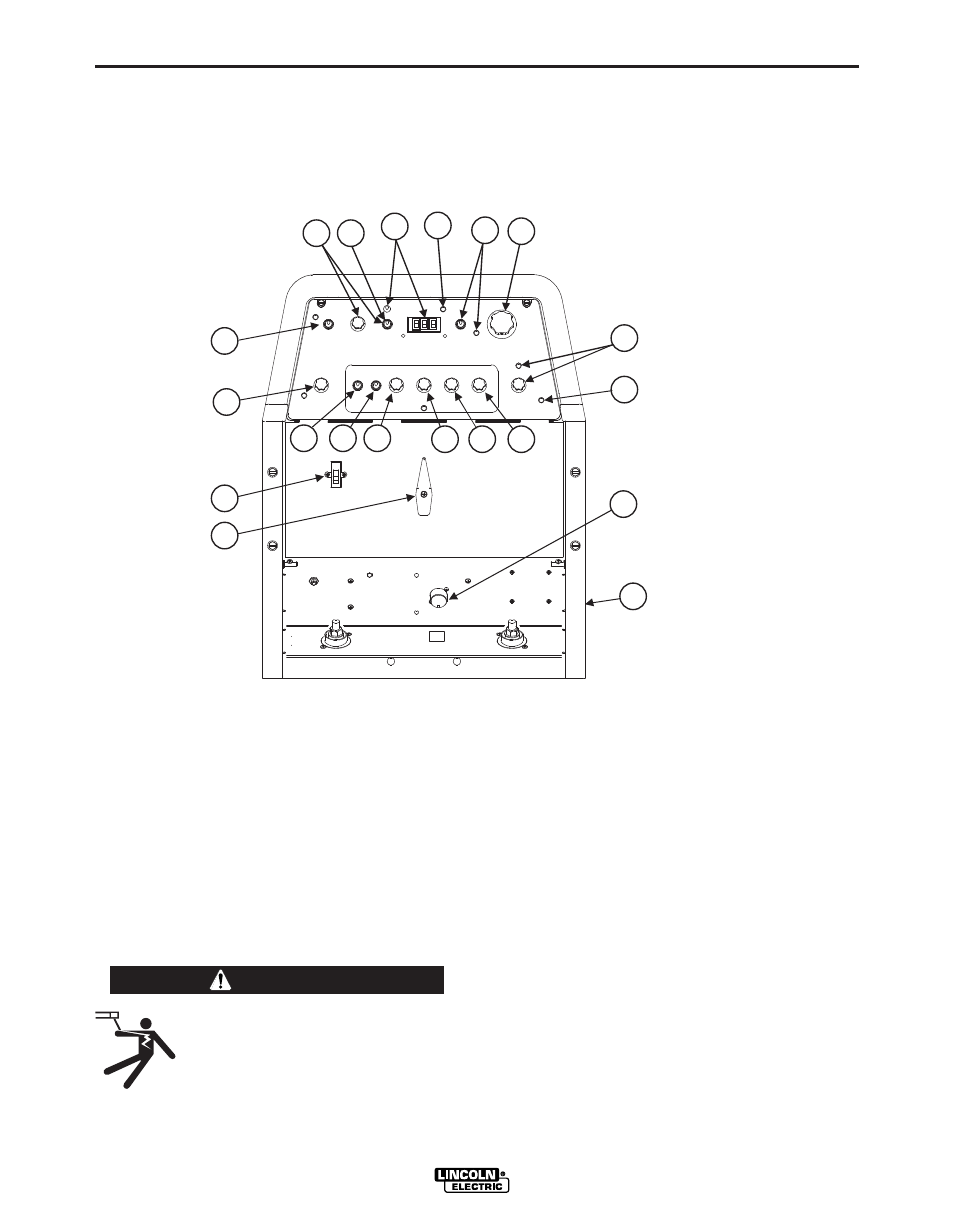

The Front Control Panel contains the knobs and switches necessary for adjusting the operation of the Precision

TIG 375, with function indicator lights and an electronic display for volts and amps. The components are

described below:

FIGURE B.1 - CONTROL PANEL

WARNING

1

2

3

4

5

9

6

13

11

10

7

7a

14

15

16

17

(Shown without hinged stud cover.)

12

WORK

STICK

8

9

19

1. POWER SWITCH

2. POLARITY SWITCH

3. MODE SWITCH

4. AC BALANCE CONTROL

5. LOCAL/REMOTE CURRENT CONTROL

SWITCH

6. MAXIMUM OUTPUT CONTROL

7. MINIMUM OUTPUT CONTROL AND

DISPLAY SWITCH

7a . MENU

BUTTON

AND

DISPLAY

SWITCH

8. DIGITAL

METER

AND

DISPLAY

SWITCH

9. POSTFLOW TIME

10. THERMAL SHUTDOWN LIGHT

11. REMOTE RECEPTACLE

12. TRIGGER SWITCH

13. PULSE / SPOT MODE SWITCH

14. PULSE FREQUENCY CONTROL

15. PULSE % ON TIME CONTROL

16. PULSE BACKGROUND CURRENT

CONTROL

17. DOWNSLOPE TIME

18. INTERNAL SETUP SELECTIONS (not

shown)

19. HIGH FREQUENCY INTENSITY

CONTROL (NOT SHOWN LOCATION

ONLY)