Installation, Warning – Lincoln Electric PRECISION TIG IM936 User Manual

Page 12

A-5

INSTALLATION

PRECISION TIG 375

A-5

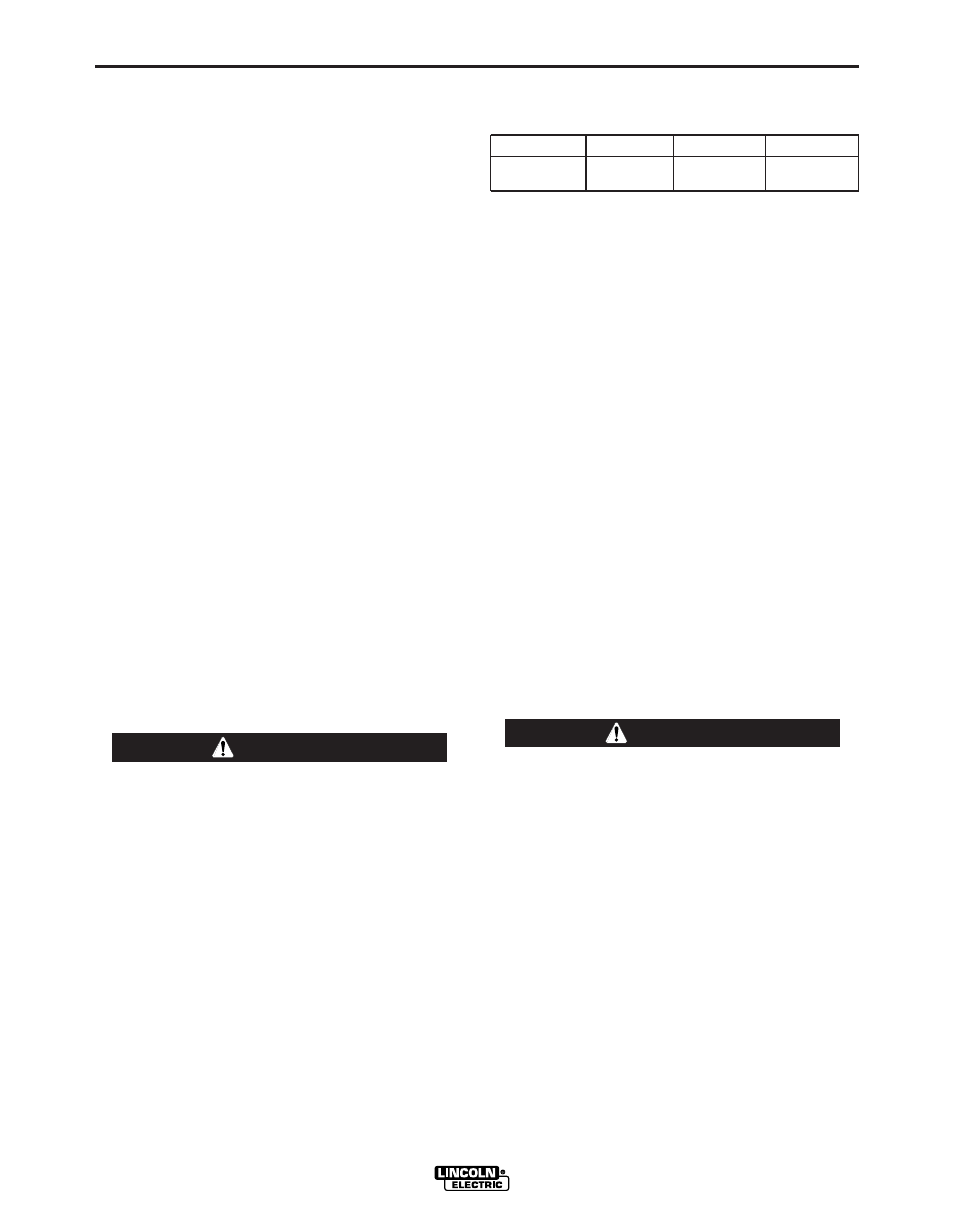

Recommended Cable Sizes for Combined Lengths of

Copper Work and Electrode Cables using 75

o

C Wire:

Machine Rating

0 to 100 Ft. 101 to 200 Ft 201 to 250 Ft

375A/40% #1 (42.4 mm2) 1/0 (53.5 mm2) 2/0 (67.4 mm2)

WORK CABLE CONNECTION

A 15’ (2/0) weld cable with clamp is available (K2150-1).

Otherwise, it is user provided.

With power source off, connect a separate work cable

to the 1/2-13 threaded "WORK" stud of the welder, and

secure a tight connection with the flange nut provided.

The work cable should be routed through the cable

strain relief hole provided in the base directly below the

welding output terminal.

Note: If the Precision TIG is equipped with an Under-

Cooler or Under-Storage unit, the coiled work cable

and clamp, or excess work cable length, may be con-

veniently stored in the drawer while remaining con-

nected.

STICK ELECTRODE CABLE CONNECTION

If manual stick welding is desired, with power source

off, connect a stick electrode cable to the 1/2-13

threaded "STICK Electrode" stud of the welder, and

secure a tight connection with the flange nut provided.

The electrode cable should be routed through the

cable strain relief hole provided in the base directly

below the welding output terminal.

DISCONNECT STICK ELECTRODE WELDING

CABLE WHEN TIG WELDING.

EVEN THOUGH HI-FREQ IS NOT APPLIED TO THE

PRECISION TIG STICK TERMINAL, IT WILL BE

ELECTRICALLY "HOT" TO WORK WHEN TIG

WELDING.

------------------------------------------------------------------------

Welders are shipped connected for the highest input

voltage as listed on the rating plate. To change this

connection, designations on the reconnect panel LOW,

MID, and HIGH correspond to the name plated input

voltages of a triple voltage welder. Dual voltage

welders use only LOW and HIGH.

EXAMPLE: This model has a voltage range for LOW

and MID connections: LOW is 220-230V, MID is 380-

400V and High is 415V.

Reconnect the jumper strap to the terminal stud corre-

sponding to the input voltage level used. Make sure all

connections are tight.

Fuse the input circuit with the recommended super lag

fuses or delay type1 circuit breakers. Choose an input

and grounding wire size according to local or national

codes or use Section A-2. Using fuses or circuit break-

ers smaller than recommended may result in "nui-

sance" tripping from welder inrush currents even if not

welding at high currents.

Unbalanced AC TIG welding draws higher input cur-

rents than those for Stick, DC TIG, or Balanced AC TIG

welding. The welder is designed for these higher input

currents. However, where unbalanced AC TIG welding

above 275 amps is planned, the higher input currents

require larger input wire sizes and fuses per Section A-

2.

OUTPUT CABLES, CONNECTIONS AND

LIMITATIONS

• To avoid being startled by a high frequency

shock, keep the TIG torch and cables in good

condition

• Turn the power switch of the power source OFF

before installing adapters on cable or when con-

necting or disconnecting adapter plugs to power

source.

-----------------------------------------------------------------------

Refer to Figure A.2 for the location of the WORK and

STICK terminals, as well as the TIG Torch connection

panel.

WARNING

WARNING