Striping operation – AIRLESSCO Spray & Stripe 3600 User Manual

Page 15

1. Choose handle location

The choices are, installing the handle opposite of the

single wheel assembly (standard set up) or placing

the handle directly over the single wheel assembly.

The handle location is really a matter of personal

preference, however having the handle away from

the single wheel assembly allows for easier loading/

unloading from a van or truck.

2. Cable Tension Adjustment

Once the handle and gun arm assemblies are set up to

the preferred positions, pressurize the unit and trigger

each gun to ensure that they activate and release

correctly. If not, adjust the cable tension as follows:

a. Locate the adjustment knobs on the base of the

gun trigger, where the cable connects to the gun

trigger assembly.

b. Loose the locking nut & move the adjusting screw

until the slack has been removed from the cable.

c. Tighten locking nut and retest gun triggers for

proper function.

Note: There is an additional cable adjustment

where the cable attaches to the gun holder

assembly. Use only if the gun trigger adjustment

is insuffi cient.

3. Miscellaneous Operations

CURBS: To paint at a 90 degree angle to spray the

sides of curbs install a part # 032-028 swivel between

gun head and tip guard and aim guard sideways

towards the curb.

WIDE STRIPES: Install wider fan striping tips and

raise the gun height to achieve the desired width line.

STENCILS: Install standard spray tip on the outer

gun. Rotate gun to remove from the gun holder and

use the gun to spray within your stencils. Use of an

extension pole will make this job a lot easier on the

operators back and is highly reccomended.

STANDARD PAINTING: Install the appropriate

size and type of paint spraying tip (standard paint

spray, “W” wide pattern, or “Fine Finish”). Remove

gun and spray just as you do for stencils. Additional

paint hose may be required depending on the

distance between the job and the equipment.

Striping Operation

13

4.

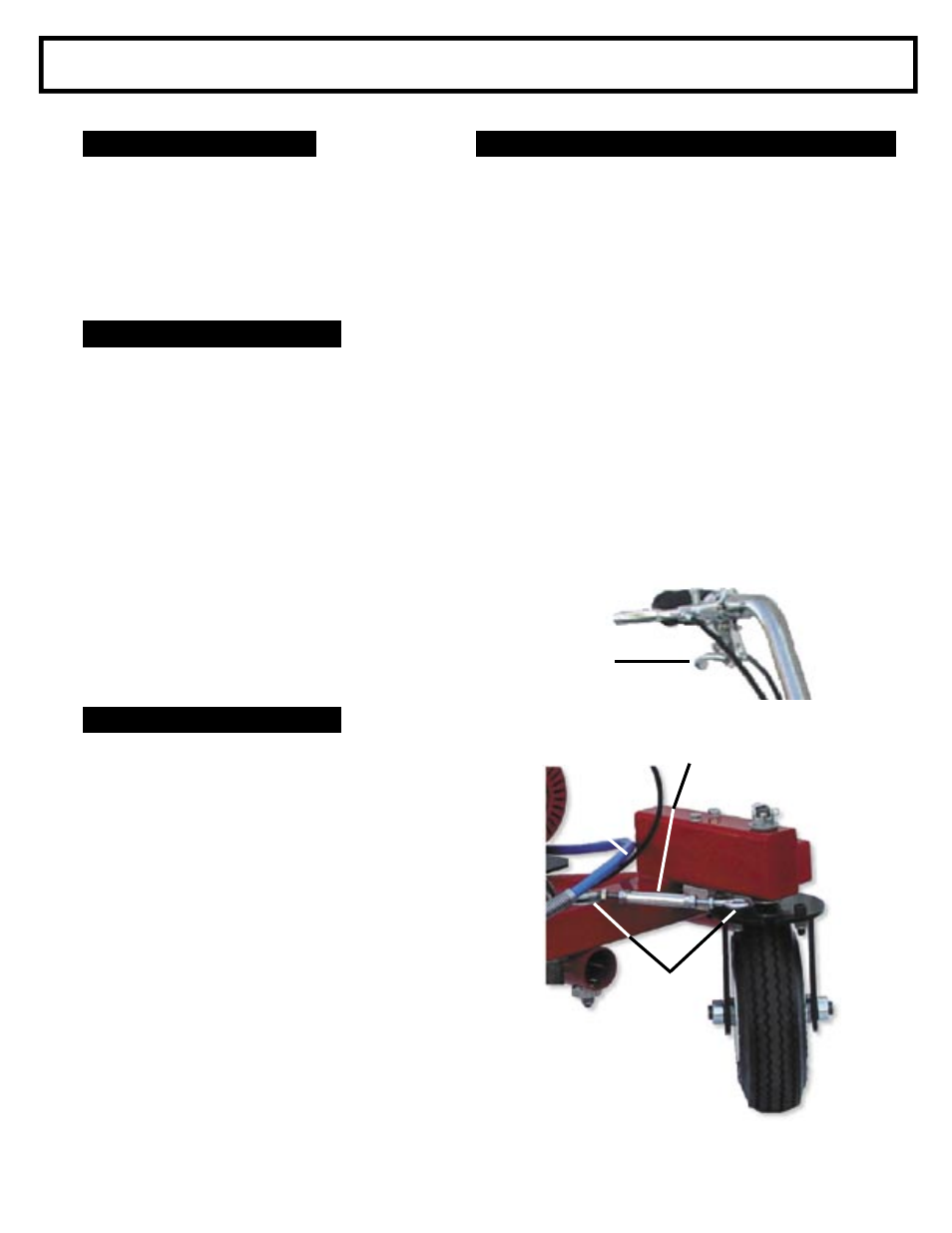

Setting the Swivel Wheel with RADIUS MEMORY

™

Refer to fi gure below

a. Pull back on the swivel wheel trigger to adjust the

wheel to desired angle.

b. To set the angle for constant arch loosen the jam

nuts on the Turnbuckle. Place Turnbuckle onto

the mounting nub located on the striper frame.

Adjust the turnbuckle until it fi ts over the mounting

nub located on the wheel frame. Tighten jam nuts

on the turnbuckle to affi x the length.

Note: If you have archs that you paint regularly, purchase

additional Turnbuckles (P.N. 136-163) and keep them set to

those arc sizes for easy use.

Mounting Nubs

Turnbuckle

Wheel Release