Warning, Avertissement – Lennox Hearth INTERTEK LMBV-42REN User Manual

Page 8

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOX HEARTH PRODUCTS • MERIT

®

SERIES B-VENT GAS FIREPLACES • 42" LMBV MODELS • INSTALLATION INSTRUCTIONS

All appliances are equipped with a gas flex line

and shutoff valve attached directly to the gas

control valve. To quickly and easily complete

the gas line routing, use the gas flex line kit.

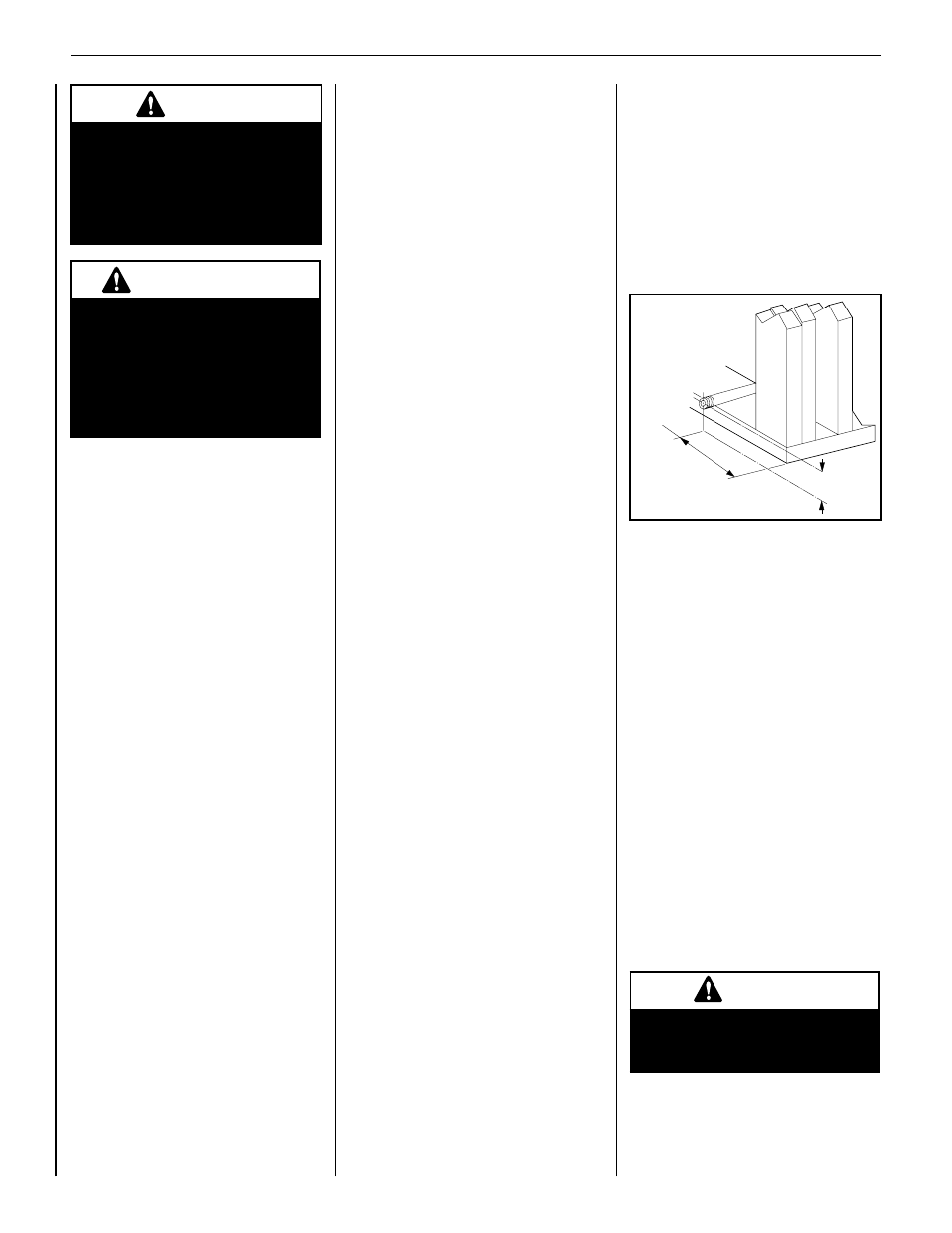

Step 2. Route Gas Supply Line

Refer to Figure 9. Using techniques and materi-

als prescribed by local and/or national codes. It

is recommended that a gas line of 1/2" or greater

diameter be used to allow full gas volume to

the fireplace. Undue pressure loss will occur if

the pipe is too small. The appliance, as set up

at the factory, is best suited for use with a gas

line routed from the right side. The gas line may

however be alternately routed from the left side.

Figure 9

RIGHT

SIDE

7-3/4"

(197 mm)

3-3/8"

(86 mm)

NOTE: Ensure the Millivolt valve wire is not

routed through the same hole as the gas line.

Route the Millivolt wire through the opposite

side from the gas line.

When rigid pipe is used, an ANSI approved

manual shut-off valve and union must be

installed upstream of the fireplace.

Ensure that a sediment trap is installed in the

existing gas line, if not, install a sediment trap

upstream to prevent moisture and contaminants

from passing through trap to the appliance

controls and burners. Failure to do so could

prevent the appliance from operating reliably.

An external regulator must be used on all pro-

pane (L.P.G). appliances to reduce the supply

tank pressure to 13" w.c. (maximum). Any

copper tubing used to supply propane (L.P.G).

from the tank must be internally tinned.

ImpORTANT: HOLD GAS vALve SeCUReLY TO

pReveNT mOvemeNT WHeN CONNeCTING TO

INLeT GAS LINe

WARNING

CONNeCTING DIReCTLY TO AN UN-

ReGULATeD pROpANe (L.p.G). TANK

mAY CAUSe AN expLOSION.

INSTALLING THe FIRepLACe

Step 1. Construct Appliance Framing

Frame appliance enclosure as illustrated in

Figure 8.

NOTE: The nailing flanges, combustible framing

members and screw heads located in areas

directly adjacent to the nailing flanges, are

EXEMPT from the 1/2" clearance to combustible

requirements for the firebox wrapper. Combus-

tible framing may be in direct contact with the

nailing flanges and may be located closer than

1/2" from screw heads and the firebox wrapper

in areas adjacent to the nailing flanges. Frame

the opening to the exact dimensions specified

in the framing details of this manual.

NOTE: The framed depth, 21-5/8" (549 mm)

from a framed wall, must always be measured

from a finished surface. If a wall covering such

as drywall is to be attached to the rear wall,

then the 21-5/8" (549 mm) must be measured

from the drywall surface. It is important that

this dimension be exact.

If the appliance is to be elevated above floor

level, a solid continuous platform must be

constructed.

The header may rest on the top metal spacers,

but must not be notched to fit around them.

Consult all local codes.

TYpICAL INSTALLATION SeQUeNCe

The typical sequence of installation is outlined

below; however, each installation is unique,

resulting in variations to the steps described

herein.

Framing Specifications ...................... page 6

Pre-Installation Notes ....................... page 6

Installing the Fireplace:

Step 1. Construct Appliance

Framing ......................Page 6

Step 2. Route Gas Line .................Page 7

Step 3. Position Appliance ............Page 7

Step 4. Install Vent System and

Exterior Termination ...Page 7

Step 5. Field Wiring; Install (Optional)

Wall Switch ................Page 8

Step 6. Connect to Gas Line .........Page 8

Step 7. Install (Optional) Outside

Air Kit .........................Page 9

Step 8. Install Logs and

Glowing Embers .........Page 10

Appliance Operation:

Step 9. Check Appliance

Operation ....................Page 10

Manual Limit Switch .... Page 10

Millivolt Checkout ........ Page 10

Electronic Checkout ..... Page 10

Step 10. Adjust Burner ...................Page 11

Step 11. Attach "Safety-in-

Operation" Warnings ..... page 12

WARNING

Failure to position the parts in

accordance with these diagrams

or failure to use only parts specifi-

cally approved with this appliance

may result in property damage or

personal injury.

AveRTISSemeNT

Risque de dommages ou de

blessures si les pièces ne sont

pas installées conformément à

ces schémas et ou si des pièces

autres que celles spécifiquement

approuvées avec cet appareil sont

utilisées.

pRe-INSTALLATION STepS

The fireplace may be installed directly on a

combustible floor or raised on a platform of

an appropriate height. Do not place fireplace on

carpeting, vinyl or other soft floor coverings. It

may, however, be placed on flat wood, plywood,

particle board or other hard surfaces. Be sure

fireplace rests on a solid continuous floor or

platform with appropriate framing for support

and so that no cold air can enter the room from

under the fireplace.

The fireplace may be positioned and then the

framing built around it, or the framing may be

constructed and the fireplace positioned into

the opening.

Usually, no special floor support is needed for

the fireplace, however, to be certain:

1. Estimate the total weight of the fireplace

system and surround materials such as

brick, stone, etc., to be installed.

2. Measure the square footage of the floor

space to be occupied by the system, sur-

rounds and hearth extensions.

3. Note the floor construction, i.e. 2 x 6’s, 2 x

8’s or 2 x 10’s, single or double joists, type

and thickness of floor boards.

4. Use this information and consult your lo-

cal building code to determine if you need

additional support.

If you plan to raise the fireplace and hearth

extension, build the platform assembly then

position fireplace and hearth extension on

top. Secure the platform to the floor to prevent

possible shifting.

7-5/8"

(194mm)

3-1/8"

(79mm)