Warning, Never use an open flame to check for leaks – Lennox Hearth INTERTEK LMBV-42REN User Manual

Page 11

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOX HEARTH PRODUCTS • MERIT

®

SERIES B-VENT GAS FIREPLACES • 42" LMBV MODELS • INSTALLATION INSTRUCTIONS

NOTE: The gas supply line

must be installed in accor-

dance with building codes

by a qualified installer

approved and/or licensed

as required by the locality.

In the Commonwealth of

Massachusetts, installation

must be performed by a

licensed plumber or gas

fitter.

Gas

Valve

3/8" NPT x

Flare Fitting

3/8" Flex Tubing

3/8" Nipple

3/8" Union

3/8" Close

Nipple

3/8" Shut-off Valve

1/2" x 3/8"

Reducer

Gas

Stub

1/2" x 3/8" Flare

Shut-off Valve

Gas Solid Line Connector

Gas Flex Line Connector

*Sediment

Trap

3"

Min

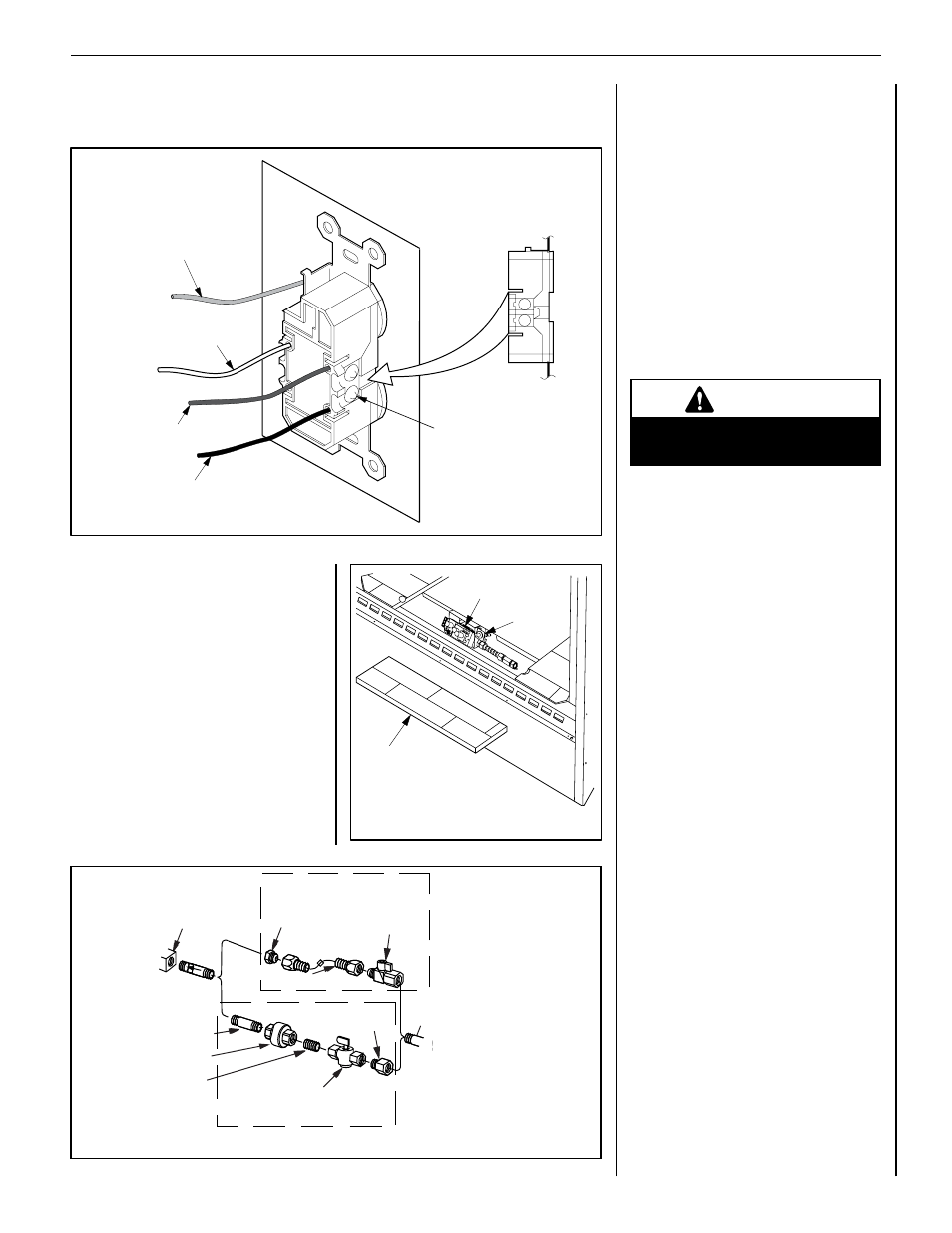

Figure 16 - Gas Connection

Step 6. Connect to Gas Line

Make gas line connections. All codes require a

shut-off valve mounted in the supply line. Figure

16 illustrates two methods for connecting the

gas supply. The flex-line method is acceptable

in the U.S., however, Canadian requirements

vary depending on locality. Installation must be

in compliance with local codes. The gas control

valve is located in the lower control compart-

ment. To access the valve remove the refractory

access panel and set aside (Figure 15 ).

The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port.

The electronic control valve has a 1/2" (13 mm)

NPT thread inlet port and is fitted with a 1/2" x

3/8" (13 mm x 10 mm) NPT fitting.

Both the millivolt and electronic models are

fitted with a 3" (76 mm) long nipple, 3/8" NPT.

Plan the connections accordingly.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane

applications).

Figure 15

Refractory

Access Panel

SIT Valve Shown

Gas Controls

on Valve

Piezo

Igniter

Figure 14

NOTE: Supply wires may be alternatively connected to the outlet using the screw terminals,

however the black supply wire must be wired to a terminal that is opposite (across the outlet) the

point where the white supply wire is connected.

White

(Supply)

Black

(Supply)

Bipolar

Terminal

Screw

120 Vac

60 Hz

Green Wire Ground

Connection

Red

(Supply)

120 Vac

60 Hz

120 Vac

60 Hz

Turn on gas supply and test for gas leaks, us-

ing a gas leak test solution (also referred to as

bubble leak solution).

NOTe: Using a soapy water solution (50%

dish soap, 50% water) is an effective leak test

solution but it is not recommended, because

the soap residue that is left on the pipes/fittings

can result in corrosion over time.

A. Light the appliance (refer to the lighting

instructions label in the control compartment

or in the Homeowner's Care and Operation

Instructions).

b. Brush all joints and connections with the

gas leak test solution to check for leaks. If

bubbles are formed, or gas odor is detected,

turn the gas control knob to the “OFF” posi-

tion. Either tighten or refasten the leaking

connection and retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free,

observe the individual tongues of flame on

the burner. Make sure all ports are open and

producing flame evenly across the burner. If

any ports are blocked, or partially blocked,

clean out the ports.

WARNING

Never use an open flame to

check for leaks.

TeST ALL CONNeCTIONS FOR GAS LeAKS

(FACTORY AND FIeLD):