Theory of operation, Control board, Power wave 455/r – Lincoln Electric POWER WAVE SVM173-A User Manual

Page 41

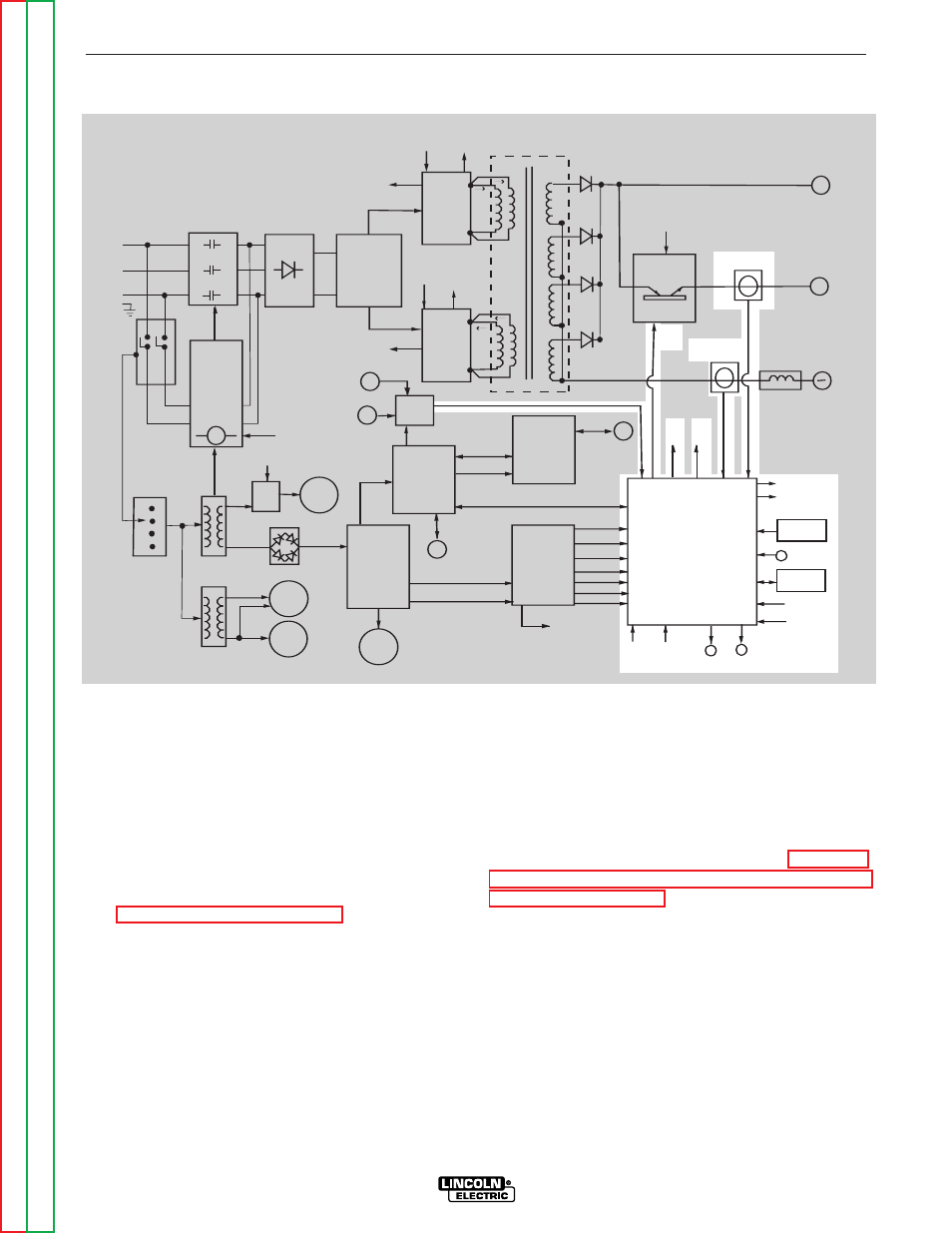

CONTROL BOARD

The Control Board performs the primary interfacing

functions to establish and maintain output control of the

Power Wave 455R machine. The function generator

and weld files exist within the Control Board hardware

and software. Digital command signals and feedback

information is received and processed at the Control

Board. Software within the Control Board processes

the command and feedback information and sends the

appropriate pulse width modulation (PWM) signals

(see PULSE WIDTH MODULATION in this section) to

the switch board IGBTs. In this manner, the digitally

controlled high-speed welding waveform is created.

The Control Board also monitors and controls the STT

(Surface Tension Transfer) circuitry incorporated in the

Power Wave 455R. STT output currents and arc volt-

ages are monitored, and the appropriated gate firing

signals are applied (or removed) from the STT

Chopper Board and switch boards to create a low spat-

ter, low fume MIG welding process. See GENERAL

DESCRIPTION OF STT (SURFACE TENSION

TRANSFER PROCESS) in this section.

In addition, the Control Board monitors the ther-

mostats, the main transformer primary currents and

input filter capacitor voltages. Depending on the fault

condition, the Control Board will activate the thermal

and/or the status light and will disable or reduce the

machine output. In some conditions the input contac-

tor will be de-energized.

E-7

E-7

THEORY OF OPERATION

POWER WAVE 455M/MSTT

FIGURE E.6 – CONTROL BOARD

+

+

INPUT

BOARD

RECONNECT

SWITCH

LEFT

SWITCH

BOARD

RIGHT

SWITCH

BOARD

INPUT

RECTIFIER

CR1

GATEWAY

BOARD

DC

BUS

BOARD

FEED

HEAD

BOARD

POWER

BOARD

CONTROL

BOARD

STT CHOPPER

BOARD

OUTPUT

CHOKE

STT

ELECTRODE

TERMINAL

ELECTRODE

TERMINAL

THERMOSTATS

T1

T2

AUX

RECONNECT

RELAY

WATER

COOLER

115 VAC

RECP.

115 VAC

FAN

ARC LINK

WIRE

FEEDER

RECP.

S1

S6

CONNECTION

TO WIRE

DRIVE

S1

S6

VOLT

SENSE

BOARD

MAIN

TRANSFORMER

S5

CONTACTOR AND PRECHARGE

CONTROL SIGNALS FROM

CONTROL BOARD

FROM CONTROL

BOARD

2

4

V

A

C

115 VAC

52 VAC

230 VAC

40 VDC

40 VDC

40 VDC

+20 VDC

TO

CHOPPER

BOARD

40 VDC

ARC LINK

CONNECTION

TO

ROBOT

VOLTAGE SENSE

OUTPUT

+20 VDC FROM

POWER BOARD

CT CURRENT

TO CONTROL

BOARD

CAP. V/F

FEEDBACK

CAP. V/F

FEEDBACK

IGBT DRIVE

FROM

CONTROL

BOARD

CT CURRENT

TO CONTROL

BOARD

-15 V

+15 V

+5 V

+5 V ARC LINK

+5V RS232

+15V SPI

STATUS THERMAL

LIGHT LIGHT

S2 WORK

SENSE

LEFT S.B.

CAP. V/F

RIGHT S.B.

CAP. V/F

S3

RS232

LEFT CT

CURRENT

FB

C

U

R

R

E

N

T

F

B

S

T

T

F

B

STT

DRIVE

ARC LINK

IGBT

DRIVES

TO

LEFT

S.B.

TO

RIGHT

S.B.

67A

67B

SW1

BUS BOARD

RECTIFIER

CURRENT

TRANSDUCER

CURRENT

TRANSDUCER

OUTPUT DIODES

D1 -D4

115 VAC

40 VDC

DEVICE NET

VOLTAGE SENSE SELECT

IGBT DRIVE

FROM

CONTROL

BOARD

+5V SPI

RIGHT CT

CURRENT

FB

TO FAN RELAY

CONTACTOR AND

PRECHARGE

CONTROL SIGNALS

65 VDC

WORK

TERMINAL

POWER WAVE 455/R