Operation, Welding mode descriptions – Lincoln Electric POWER WAVE SVM173-A User Manual

Page 25

WELDING MODE DESCRIPTIONS

CONSTANT VOLTAGE WELDING

For each wire feed speed, a corresponding voltage is

preprogrammed into the machine through special soft-

ware at the factory. The preprogrammed voltage is the

best average voltage for a given wire feed speed. With

synergic programs, when the wire feed speed changes,

the Power Wave will automatically adjust the corre-

sponding voltage.

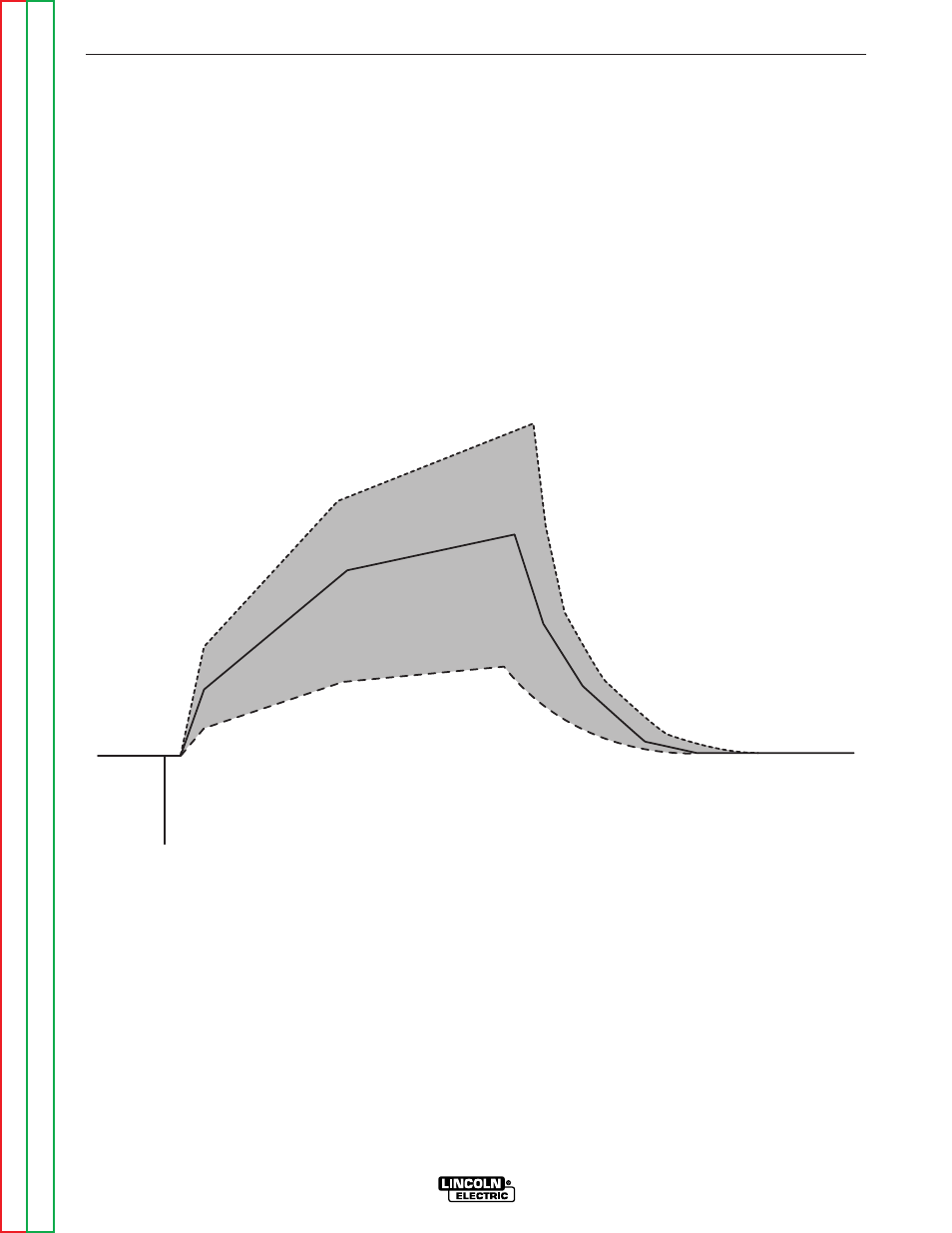

Wave control adjusts the inductance of the wave

shape. (This adjustment is often referred to as "pinch".

Inductance is inversely proportional to pinch.) In-

creasing wave control greater than 0 results in a harsh-

er, colder arc, while decreasing the wave control to less

than 0 provides a softer, hotter arc. (See Figure B.2.)

B-7

B-7

OPERATION

POWER WAVE 455M/MSTT

Current

Time

Wave Control +10.0

Wave Control -10.0

Wave Control 0.00

FIGURE B.2 – CV WAVE CONTROL CHARACTERISTICS