Troubleshooting the millivolt gas control system – Lennox Hearth EDVI25 User Manual

Page 20

0

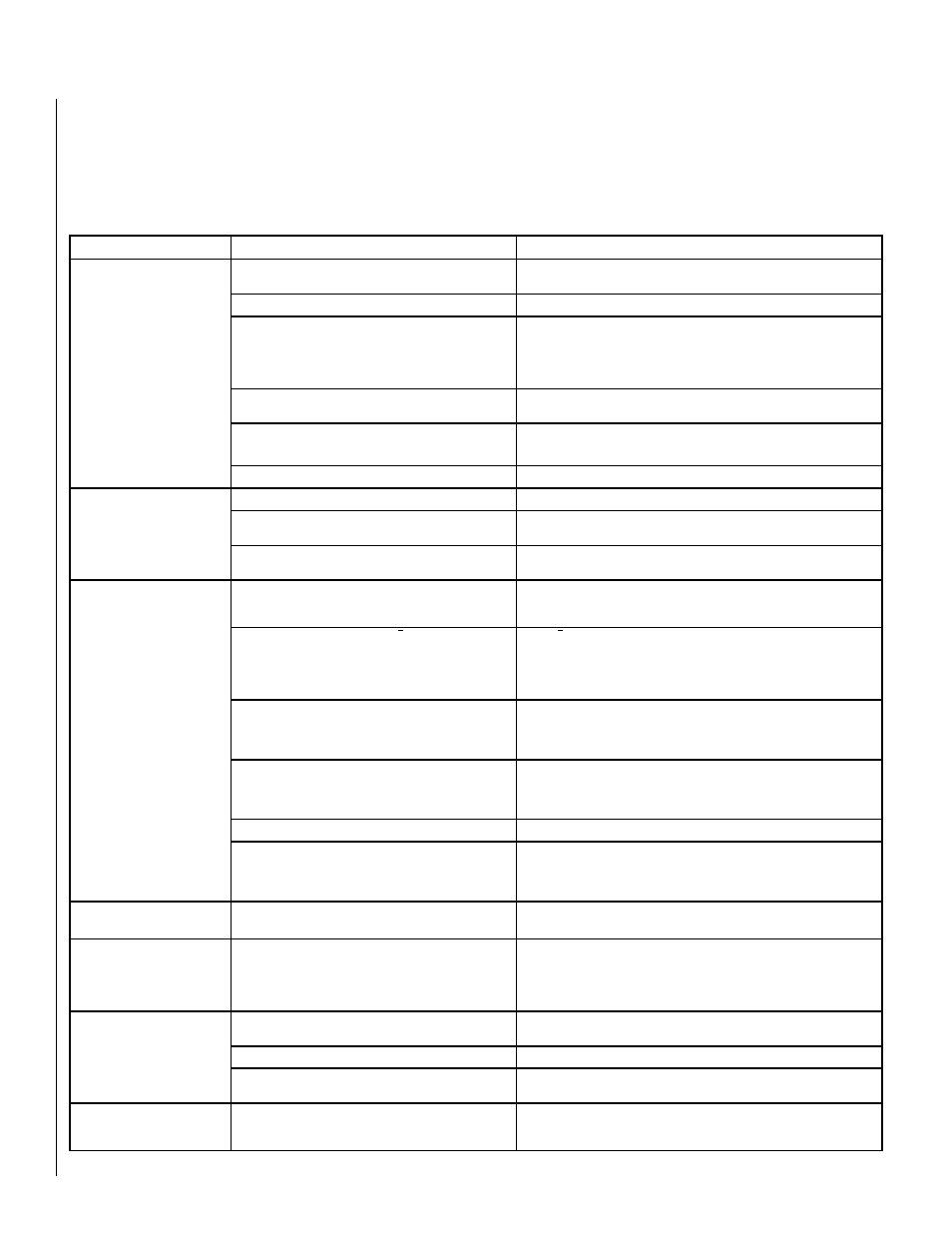

TROUBLESHOOTING THE MILLIVOLT GAS CONTROL SYSTEM

Note: Before troubleshooting the gas control system, be sure external gas shut off valve (located at gas supply inlet) is

in the “ON” position.

Important: Valve system troubleshooting should only be accomplished by a qualified service technician.

SYMPTOM

POSSIBLE CAUSES

CORRECTIVE ACTION

1) Spark igniter will not light

pilot after repeated triggering of

igniter button.

WARNING: IF THE PILOT WILL

NOT LIGHT AFTER ONE MINUTE

OF ATTEMPTING, WAIT FOR AT

LEAST FIVE MINUTES FOR GAS

TO CLEAR BEFORE ATTEMPTING

AGAIN.

A. Electrode wire (at Piezo Igniter) not pushed completely

on.

• Check connection

B. Piezo igniter is defective

• Replace piezo igniter

C. Defective or misaligned electrode at pilot (spark at

electrode)

• Using a match, light pilot. If pilot lights, turn off pilot and trigger the igniter

button again. If pilot lights, an improper gas mixture caused the bad lighting

and a longer purge period is recommended. If pilot will not light – check gap at

electrode and pilot – It should be between 1/8” and 3/16.” If the gap is out of this

range, adjust the gap or replace the pilot assembly. (Page 13, Figure 38)

D. Incorrect lighting procedure

• Carefully follow the lighting instructions on Pages 16 &17 or as found in

the insert control compartment.

E. Gas supply problem

• Check for multiple gas shut-offs. Check gas supply lines.· Check inlet gas

pressure. It should be within the limits as marked on the rating plate.

F. Pilot orifice plugged

• Clean or replace pilot orifice

) Pilot will not stay lit after

carefully following the lighting

instructions.

A. Thermocouple is not firmly connected to control valve

• Check connection at valve

B. Pilot flame is not directed to top of thermocouple

• Ensure thermocouple is fully inserted into pilot assembly. Clean and/or adjust

pilot for maximum flame impingement on thermocouple if necessary.

C. Thermocouple is defective. The millivolt production should

be a minimum of 14 MV with pilot only.

• Replace thermocouple

3) Pilot flame stays lit, but

main burner will not light. (Valve

pilot/on/off knob is in ON position,

on/off switch, wall thermostat or

remote control is set to ON).

Read important note below.

IMPORTANT NOTE: If an

optional Remote Switch*

is used for burner opera-

tion and if the standard

burner OFF/ON switch is

still installed on appli-

ance, it must be in the

"OFF" position.

A. Burner control switch (on/off switch, wall thermostat or

remote control) is in “OFF” position; or thermostat (if installed)

is set to a temperature setting that is too low.

• Turn burner on/off switch on and/or refer to instructions provided with

optional thermostat or remote control, if applicable.

B. Electrical wiring is damaged or poorly connected or

remote switch is defective.

• Check wall switch and wires for proper connections. Refer to Millivolt Wiring

Diagram (Page 14, Figure 41). Jump the wire across terminals at the wall

switch, if the burner comes on, replace the defective wall switch. If okay, jumper

the wires across the wall switch wires at the valve. If the burner comes on,

wires are faulty or connections are bad.

C. One of the following components may be defective:

burner control switch, thermostat or thermopile. Thermopile:

Millivolt production should be a minimum of 325 MV with

pilot only.

• Refer to Millivolt Wiring Diagram (Page 14, Figure 41). Electrically bypass

components one at a time and replace defective item.

D. Thermopile may not be generating sufficient mil-

livolts

• Check thermopile with millivolt meter. Take reading at thermopile ter-

minals of gas valve. It should read 325 millivolts minimum with optional

wall switch “OFF.” Replace faulty thermopile if reading is below specified

minimum.

E. Plugged burner orifice

heck burner orifice for blockage and remove.

F. OFF/ON Switch & Remote Switch* are in the "ON"

position resulting in excessive resistance

When turning on the burner using a Remote Switch,* ensure that the

standard OFF/ON Switch is in the "OFF" position. If both switches are in

the ON position, it may result in excessive resistance (& millivolt drainage)

and the burner may not come on.

4) Frequent pilot/burner outage

problem

A. Pilot flame may be too low or blowing (high) causing the

pilot/valve safety to drop out.

• Clean and/or adjust pilot flame for maximum flame impingement on ther-

mocouple (Page 13, Figure 38).

5) Smell of gas

A. Pilot, gas supply system, or pilot & burner adjustment

screws on valve may be leaking. FOLLOW INSTRUCTIONS

ON THE COVER OF THIS MANUAL

• WARNING: NEVER USE AN OPEN FLAME TO CHECK FOR LEAKS.

After the gas company or fire department has given clearance to re-enter the

dwelling, have a qualified technician test all gas joints from the gas meter to

the gas heater regulator for leaks using a gas leak test solution (also referred

to as bubble leak solution).

6) A thin coating of black soot

forms on the window. NOTE: See

Page 5, Glass Cleaning.

A. Burner primary air inlet is restricted or blocked

• Ensure all openings (fresh air inlets) in the insert are free from dust and

debris. Recheck these areas periodically.

B. Flames make contact with logs or other surfaces

• Ensure ceramic logs are in their correct positions.

C. Improper venting

• Check for flue blockage, disconnected flue, improper installation. Make

appropriate corrections.

7) A white coating forms on

windows, logs, and/or inside

walls of firebox.

A. Residues/impurities being burned off or impurities in the

fuel

• Follow cleaning guidelines outlined in the MAINTENANCE section of this

manual.

*Optional Remote Switch kits: wall switch, wall thermostat or remote control.