Psl1, Psl2 – Lincoln Electric 2HBG User Manual

Page 4

PSL1

4

Pipeliner

www.lincolnelectric.com

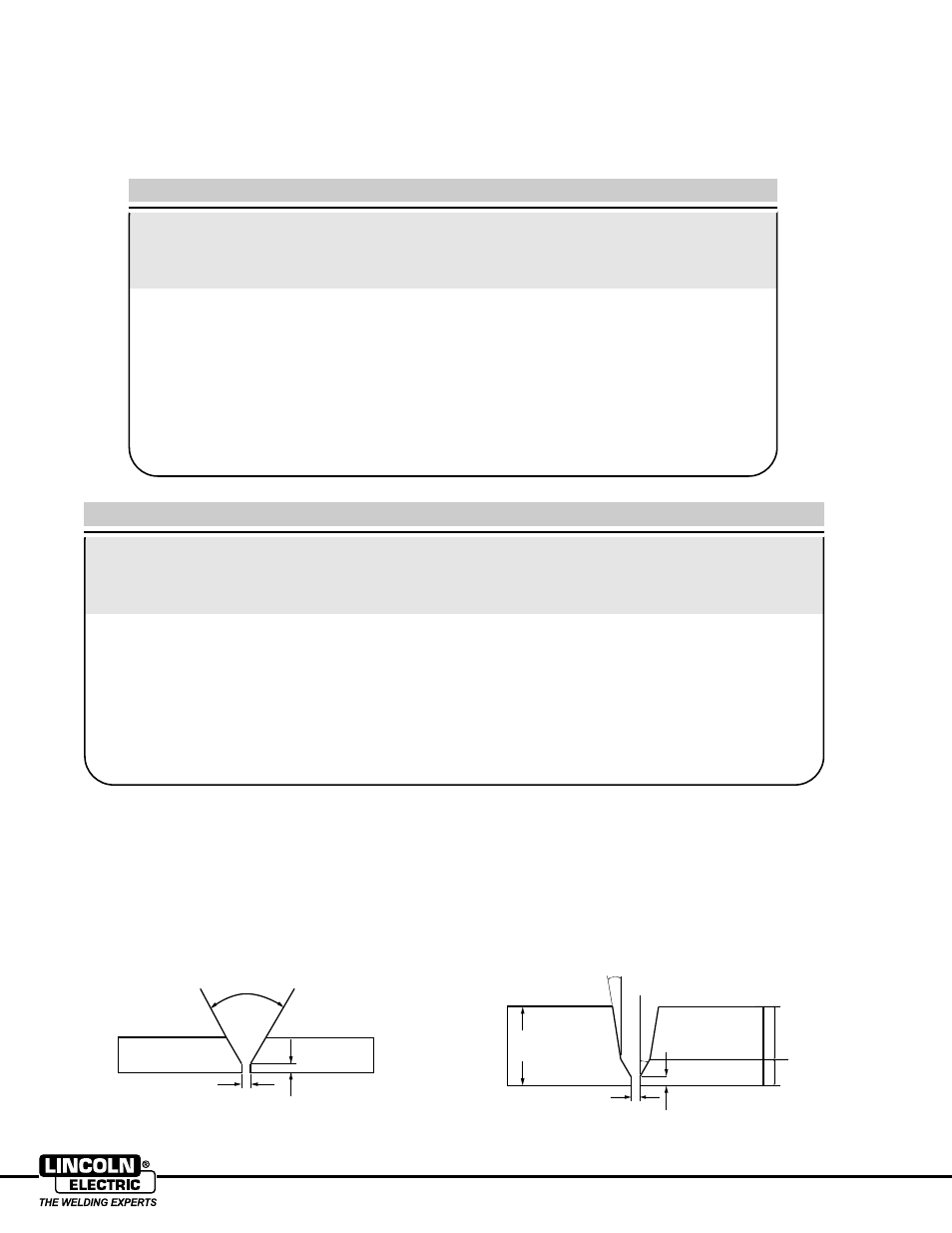

Joint Design

A customary joint preparation is commonly called an "API"

fitup. While this is not actually an API 1104 requirement,

the figures shown in the specification are drawn to have a

60 degree included angle with a 1/16" (1.6 mm) land and

1/16" (1.6 mm) gap.

As an alternative, for thicker wall pipe (>3/4", >20 mm), a

compound bevel can be used. The amount of material

required to fill a compound bevel joint is less than a 60

degree included angle preparation, so productivity may be

increased.

Pipe Grades

The primary pipe grades are classified in accordance with

the API 5L:2000 specification. This specification establishes

requirements for two product specification levels – PSL 1

and PSL 2. PSL 1 includes mandatory requirements for

chemistry, ductility, minimum yield strength and minimum

tensile strength. PSL 2 adds mandatory requirements for

maximum yield strength, maximum tensile strength and

Charpy impacts.

Recommended joint preparation

60˚

3/64-1/16 in.

(1.0-1.6 mm)

1/16-5/64 in.

(1.6-2.0 mm)

1/16 in.

(1.6 mm)

1/3 T

2/3 T

1/16-5/64 in.

(1.6-2.0 mm)

10˚

30˚

T

Wall thickness <3/4 in. (<20mm)

Wall thickness >3/4 in. (>20mm)

Ultimate

Yield Strength

Tensile Strength

Minimum

Minimum

Grade

psi

MPa

psi

MPa

A25

25,000

(172)

45,000

(310)

A

30,000

(207)

48,000

(331)

B

35,000

(241)

60,000

(414)

X42

42,000

(290)

60,000

(414)

X46

46,000

(317)

63,000

(434)

X52

52,000

(359)

66,000

(455)

X56

56,000

(386)

71,000

(490)

X60

60,000

(414)

75,000

(517)

X65

65,000

(448)

77,000

(531)

X70

70,000

(483)

82,000

(565)

PSL2

Ultimate

Ultimate

Yield Strength

Yield Strength

Tensile Strength

Tensile Strength

Minimum

Maximum

Minimum

Maximum

Grade

psi

MPa

psi

MPa

psi

MPa

psi

MPa

B

35,000

(241)

65,000

(448)

60,000

(414)

110,000

(758)

X42

42,000

(290)

72,000

(496)

60,000

(414)

110,000

(758)

X46

46,000

(317)

76,000

(524)

63,000

(434)

110,000

(758)

X52

52,000

(359)

77,000

(531)

66,000

(455)

110,000

(758)

X56

56,000

(386)

79,000

(544)

71,000

(490)

110,000

(758)

X60

60,000

(414)

82,000

(565)

75,000

(517)

110,000

(758)

X65

65,000

(448)

87,000

(600)

77,000

(531)

110,000

(758)

X70

70,000

(483)

90,000

(621)

82,000

(565)

110,000

(758)

X80

80,000

(552)

100,000

(690)

90,000

(621)

120,000

(827)